Machine vision inspection leverages high-resolution cameras and image processing algorithms to detect surface defects, ensure proper assembly, and verify product quality in real-time on production lines. X-ray inspection provides non-destructive internal examination, identifying hidden flaws such as voids, cracks, and contaminations in components and assemblies. Explore the key differences and advantages of machine vision and X-ray inspection technologies for advanced manufacturing quality control.

Why it is important

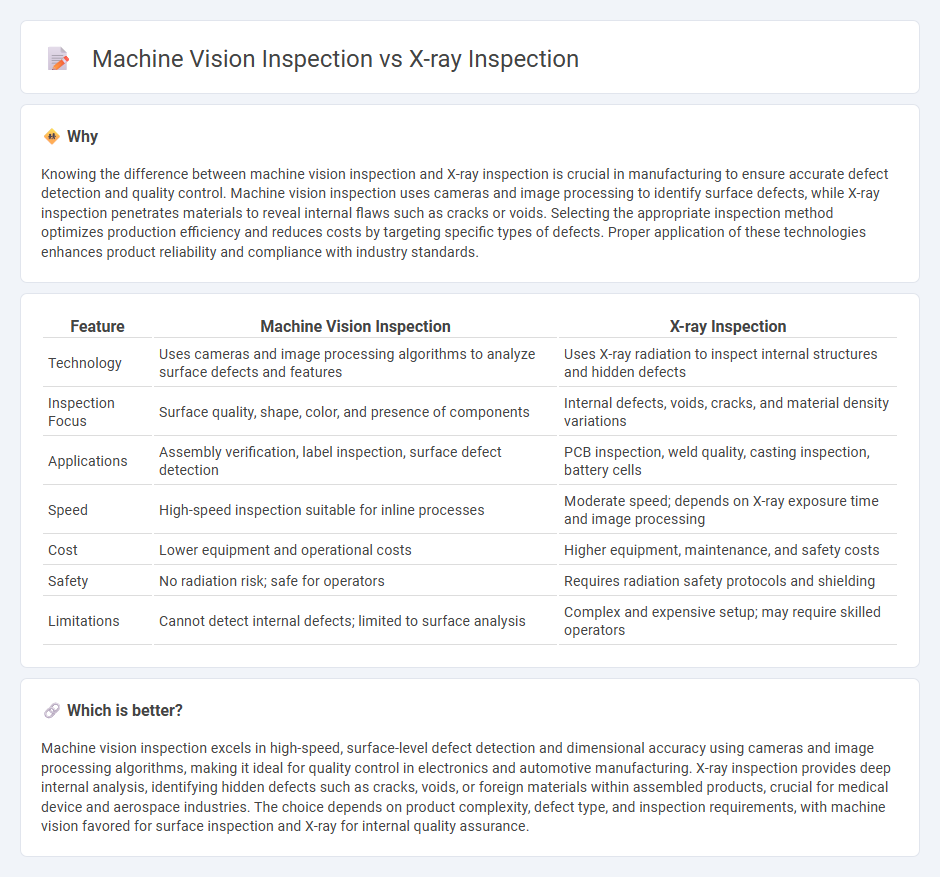

Knowing the difference between machine vision inspection and X-ray inspection is crucial in manufacturing to ensure accurate defect detection and quality control. Machine vision inspection uses cameras and image processing to identify surface defects, while X-ray inspection penetrates materials to reveal internal flaws such as cracks or voids. Selecting the appropriate inspection method optimizes production efficiency and reduces costs by targeting specific types of defects. Proper application of these technologies enhances product reliability and compliance with industry standards.

Comparison Table

| Feature | Machine Vision Inspection | X-ray Inspection |

|---|---|---|

| Technology | Uses cameras and image processing algorithms to analyze surface defects and features | Uses X-ray radiation to inspect internal structures and hidden defects |

| Inspection Focus | Surface quality, shape, color, and presence of components | Internal defects, voids, cracks, and material density variations |

| Applications | Assembly verification, label inspection, surface defect detection | PCB inspection, weld quality, casting inspection, battery cells |

| Speed | High-speed inspection suitable for inline processes | Moderate speed; depends on X-ray exposure time and image processing |

| Cost | Lower equipment and operational costs | Higher equipment, maintenance, and safety costs |

| Safety | No radiation risk; safe for operators | Requires radiation safety protocols and shielding |

| Limitations | Cannot detect internal defects; limited to surface analysis | Complex and expensive setup; may require skilled operators |

Which is better?

Machine vision inspection excels in high-speed, surface-level defect detection and dimensional accuracy using cameras and image processing algorithms, making it ideal for quality control in electronics and automotive manufacturing. X-ray inspection provides deep internal analysis, identifying hidden defects such as cracks, voids, or foreign materials within assembled products, crucial for medical device and aerospace industries. The choice depends on product complexity, defect type, and inspection requirements, with machine vision favored for surface inspection and X-ray for internal quality assurance.

Connection

Machine vision inspection and X-ray inspection are connected through their roles in enhancing quality control within manufacturing processes by detecting surface defects and internal flaws, respectively. Both technologies rely on advanced imaging and algorithms to ensure product integrity, improve precision, and reduce waste. Integrating these inspections creates a comprehensive quality assurance system that addresses both external and hidden manufacturing issues.

Key Terms

Defect Detection

X-ray inspection excels in detecting internal defects such as voids, cracks, and inclusions within materials, providing detailed subsurface analysis that machine vision inspection cannot achieve. Machine vision inspection specializes in identifying surface-level defects like scratches, misalignments, and surface contamination using high-resolution cameras and image processing algorithms. Explore in-depth comparisons and technical insights on defect detection methods to determine the best fit for your quality control needs.

Imaging Technology

X-ray inspection utilizes high-energy electromagnetic radiation to capture detailed internal images, enabling detection of hidden defects and material inconsistencies within objects. Machine vision inspection relies on cameras and optical sensors to analyze surface features, color, shape, and texture for quality control and defect identification. Discover how advanced imaging technologies enhance precision and efficiency in industrial applications.

Non-Destructive Testing

X-ray inspection excels at detecting internal defects such as voids, cracks, and inclusions within materials, offering high-resolution images that reveal hidden flaws without damaging the object. Machine vision inspection utilizes cameras and image processing algorithms to assess surface defects, alignment, and assembly integrity, providing real-time, high-speed quality control in manufacturing. Explore further to understand the applications and benefits of each non-destructive testing method in industrial quality assurance.

Source and External Links

X-ray Equipment Inspection - Ohio Department of Health - The Ohio X-ray Program inspects facilities and businesses using or installing x-ray equipment, reviewing quality assurance aspects and performing equipment tests like kVp accuracy and safety interlocks to ensure safe and compliant operation.

X-Ray Inspection Systems | Anritsu America - Anritsu provides X-ray inspection systems that detect physical contaminants and quality defects using single or dual energy technologies, supporting upstream and end-of-line product inspection to identify metal, stone, glass, or bone contaminants in manufacturing processes.

X-Ray CT Inspection Services - Nikon Metrology Inc. - Nikon offers advanced non-destructive X-ray and CT inspection services for quality assurance and metrology, capable of revealing internal defects, foreign materials, and structural inconsistencies in components through 2D and 3D imaging.

dowidth.com

dowidth.com