Closed-loop manufacturing integrates real-time feedback systems to continuously optimize production quality and efficiency, reducing waste and downtime through dynamic adjustments. Process manufacturing focuses on producing goods by combining ingredients or raw materials in batches or continuous processes, commonly used in chemical, food, and pharmaceutical industries. Explore the key differences and applications to determine the best approach for your manufacturing needs.

Why it is important

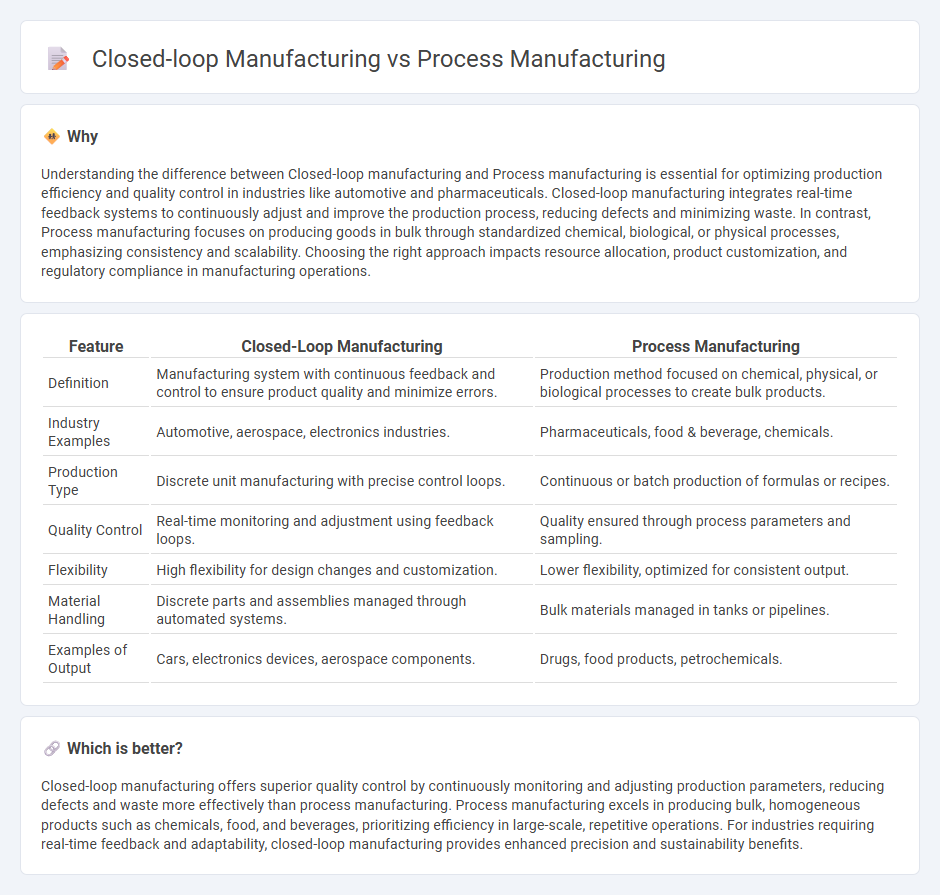

Understanding the difference between Closed-loop manufacturing and Process manufacturing is essential for optimizing production efficiency and quality control in industries like automotive and pharmaceuticals. Closed-loop manufacturing integrates real-time feedback systems to continuously adjust and improve the production process, reducing defects and minimizing waste. In contrast, Process manufacturing focuses on producing goods in bulk through standardized chemical, biological, or physical processes, emphasizing consistency and scalability. Choosing the right approach impacts resource allocation, product customization, and regulatory compliance in manufacturing operations.

Comparison Table

| Feature | Closed-Loop Manufacturing | Process Manufacturing |

|---|---|---|

| Definition | Manufacturing system with continuous feedback and control to ensure product quality and minimize errors. | Production method focused on chemical, physical, or biological processes to create bulk products. |

| Industry Examples | Automotive, aerospace, electronics industries. | Pharmaceuticals, food & beverage, chemicals. |

| Production Type | Discrete unit manufacturing with precise control loops. | Continuous or batch production of formulas or recipes. |

| Quality Control | Real-time monitoring and adjustment using feedback loops. | Quality ensured through process parameters and sampling. |

| Flexibility | High flexibility for design changes and customization. | Lower flexibility, optimized for consistent output. |

| Material Handling | Discrete parts and assemblies managed through automated systems. | Bulk materials managed in tanks or pipelines. |

| Examples of Output | Cars, electronics devices, aerospace components. | Drugs, food products, petrochemicals. |

Which is better?

Closed-loop manufacturing offers superior quality control by continuously monitoring and adjusting production parameters, reducing defects and waste more effectively than process manufacturing. Process manufacturing excels in producing bulk, homogeneous products such as chemicals, food, and beverages, prioritizing efficiency in large-scale, repetitive operations. For industries requiring real-time feedback and adaptability, closed-loop manufacturing provides enhanced precision and sustainability benefits.

Connection

Closed-loop manufacturing integrates real-time feedback and quality control into process manufacturing workflows, enhancing precision and minimizing waste. Process manufacturing relies on continuous monitoring and adjustments, which closed-loop systems facilitate through automated data collection and analysis. This synergy optimizes resource usage, reduces production errors, and improves overall efficiency in manufacturing operations.

Key Terms

Batch Production

Process manufacturing involves producing goods by combining ingredients or raw materials through chemical, biological, or physical processes, commonly used in industries like food, pharmaceuticals, and chemicals. Closed-loop manufacturing integrates real-time feedback and automated adjustments to continuously optimize batch production, enhancing quality control and minimizing waste. Discover how leveraging closed-loop systems can revolutionize batch process manufacturing efficiency and consistency.

Continuous Feedback

Process manufacturing relies on batch production with limited real-time data, often lacking immediate feedback for quality control. Closed-loop manufacturing integrates continuous feedback systems using sensors and IoT devices to monitor and adjust processes in real-time, enhancing product consistency and reducing waste. Explore the advantages of closed-loop manufacturing to optimize your production efficiency and quality control.

Quality Control

Process manufacturing involves large-scale production of goods using raw materials combined in bulk, where quality control relies heavily on standardized measurements and batch testing to ensure uniformity. Closed-loop manufacturing incorporates real-time feedback systems, continuously monitoring production variables to immediately adjust processes and maintain optimal quality standards. Explore how integrating closed-loop control can significantly enhance quality assurance in process manufacturing environments.

Source and External Links

Process Manufacturing | Propel Glossary - Process manufacturing involves transforming raw materials into finished goods through precise chemical or mechanical processes, often used in industries like pharmaceuticals and chemicals.

Process Manufacturing: Definition, Benefits, and Industries - Process manufacturing creates goods by combining components under specific conditions, commonly used in sectors like food, beverage, and pharmaceuticals.

What is Process Manufacturing? Definition and Examples - Process manufacturing involves combining supplies using a predetermined formula, often in bulk production for industries such as food, beverages, and chemicals.

dowidth.com

dowidth.com