Predictive maintenance uses real-time data and machine learning algorithms to anticipate equipment failures before they occur, minimizing downtime and reducing costs. Prescriptive maintenance goes further by not only forecasting potential issues but also recommending specific actions to optimize maintenance schedules and improve operational efficiency. Explore the differences and benefits of these advanced maintenance strategies to enhance your manufacturing processes.

Why it is important

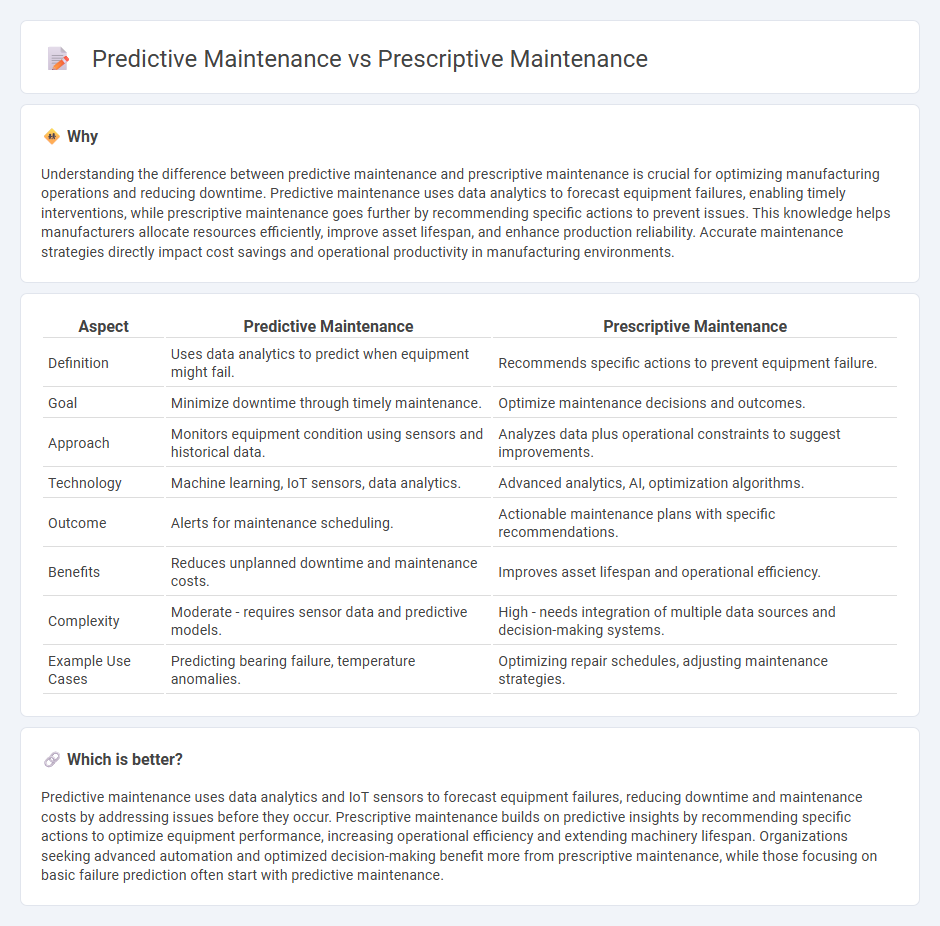

Understanding the difference between predictive maintenance and prescriptive maintenance is crucial for optimizing manufacturing operations and reducing downtime. Predictive maintenance uses data analytics to forecast equipment failures, enabling timely interventions, while prescriptive maintenance goes further by recommending specific actions to prevent issues. This knowledge helps manufacturers allocate resources efficiently, improve asset lifespan, and enhance production reliability. Accurate maintenance strategies directly impact cost savings and operational productivity in manufacturing environments.

Comparison Table

| Aspect | Predictive Maintenance | Prescriptive Maintenance |

|---|---|---|

| Definition | Uses data analytics to predict when equipment might fail. | Recommends specific actions to prevent equipment failure. |

| Goal | Minimize downtime through timely maintenance. | Optimize maintenance decisions and outcomes. |

| Approach | Monitors equipment condition using sensors and historical data. | Analyzes data plus operational constraints to suggest improvements. |

| Technology | Machine learning, IoT sensors, data analytics. | Advanced analytics, AI, optimization algorithms. |

| Outcome | Alerts for maintenance scheduling. | Actionable maintenance plans with specific recommendations. |

| Benefits | Reduces unplanned downtime and maintenance costs. | Improves asset lifespan and operational efficiency. |

| Complexity | Moderate - requires sensor data and predictive models. | High - needs integration of multiple data sources and decision-making systems. |

| Example Use Cases | Predicting bearing failure, temperature anomalies. | Optimizing repair schedules, adjusting maintenance strategies. |

Which is better?

Predictive maintenance uses data analytics and IoT sensors to forecast equipment failures, reducing downtime and maintenance costs by addressing issues before they occur. Prescriptive maintenance builds on predictive insights by recommending specific actions to optimize equipment performance, increasing operational efficiency and extending machinery lifespan. Organizations seeking advanced automation and optimized decision-making benefit more from prescriptive maintenance, while those focusing on basic failure prediction often start with predictive maintenance.

Connection

Predictive maintenance utilizes data analytics and IoT sensors to forecast equipment failures by detecting patterns and anomalies in real-time operational data. Prescriptive maintenance builds on these insights by recommending specific actions to prevent failures and optimize machine performance, combining advanced algorithms with predictive models. The integration of predictive and prescriptive maintenance transforms manufacturing operations through reduced downtime, lower maintenance costs, and enhanced asset reliability.

Key Terms

**Prescriptive Maintenance:**

Prescriptive maintenance uses advanced data analytics and machine learning algorithms to recommend specific actions that prevent equipment failures and optimize operational efficiency, going beyond merely predicting when a failure might occur. It integrates real-time sensor data, historical maintenance records, and operational parameters to generate actionable maintenance schedules tailored to individual asset conditions. Discover detailed insights on how prescriptive maintenance transforms asset management and reduces downtime.

Optimization Recommendations

Prescriptive maintenance leverages advanced analytics and machine learning to provide specific optimization recommendations, such as adjusting operational parameters and scheduling targeted interventions to minimize downtime and costs. Predictive maintenance primarily focuses on identifying potential failures before they occur by analyzing real-time sensor data and historical trends to forecast equipment health. Discover how integrating these strategies can revolutionize maintenance efficiency and extend asset lifespan.

Automated Decision-Making

Prescriptive maintenance leverages automated decision-making algorithms to provide actionable recommendations that optimize equipment uptime and reduce operational costs by anticipating failures and suggesting specific interventions. Predictive maintenance uses data analytics and machine learning models to forecast potential equipment failures before they occur, relying primarily on real-time sensor data for condition monitoring. Explore deeper insights into how automated decision-making transforms maintenance strategies by enhancing precision and efficiency in industrial applications.

Source and External Links

What is Prescriptive Maintenance? Definition and Benefits - Prescriptive maintenance is a cutting-edge approach to asset management that uses advanced analytics and machine learning to predict maintenance needs and prescribe solutions.

What Is Prescriptive Maintenance? - Prescriptive maintenance is a proactive strategy that uses machine data to determine and recommend necessary maintenance for equipment, improving reliability and reducing failures.

Prescriptive Maintenance - This strategy uses machine learning to adjust operating conditions for desired outcomes and intelligently schedule asset maintenance to minimize downtime and optimize performance.

dowidth.com

dowidth.com