Machine vision inspection enhances manufacturing quality control by using cameras and software to detect surface defects and ensure assembly accuracy quickly and non-invasively. In contrast, 3D metrology provides precise dimensional measurements and geometric analysis through laser scanners or coordinate measuring machines, critical for verifying complex part specifications. Explore how these technologies optimize production efficiency and product reliability in modern manufacturing environments.

Why it is important

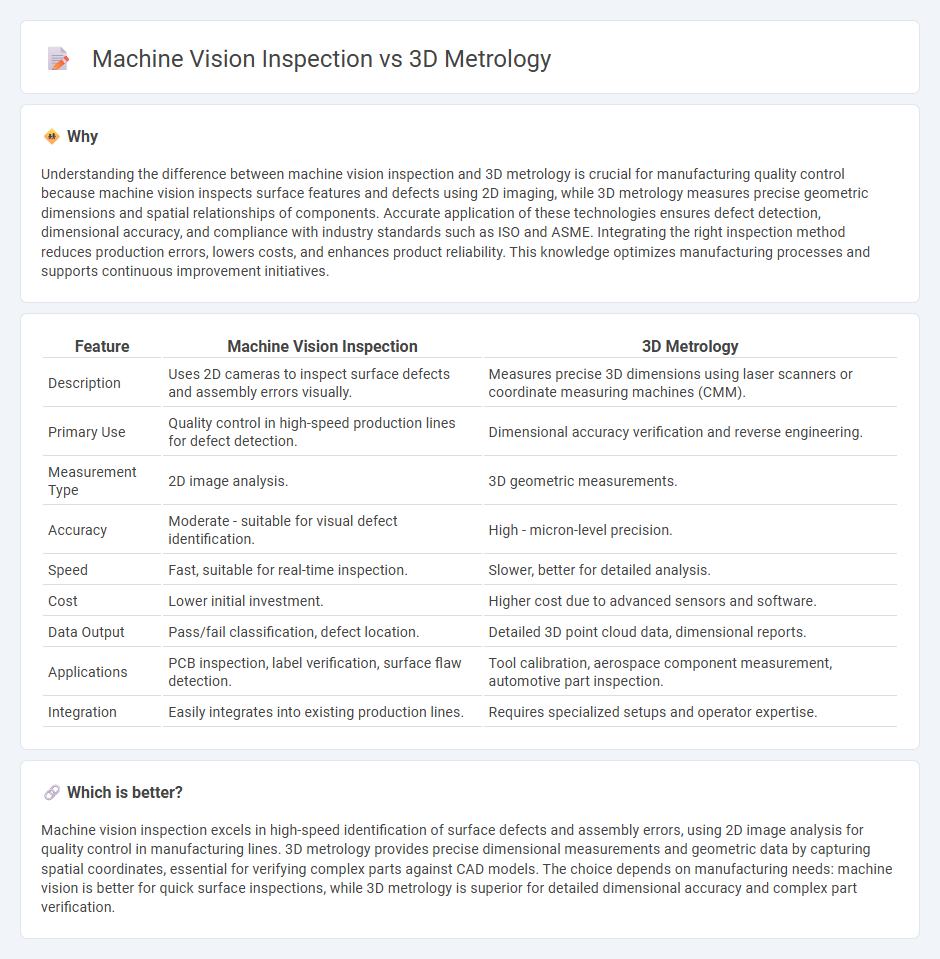

Understanding the difference between machine vision inspection and 3D metrology is crucial for manufacturing quality control because machine vision inspects surface features and defects using 2D imaging, while 3D metrology measures precise geometric dimensions and spatial relationships of components. Accurate application of these technologies ensures defect detection, dimensional accuracy, and compliance with industry standards such as ISO and ASME. Integrating the right inspection method reduces production errors, lowers costs, and enhances product reliability. This knowledge optimizes manufacturing processes and supports continuous improvement initiatives.

Comparison Table

| Feature | Machine Vision Inspection | 3D Metrology |

|---|---|---|

| Description | Uses 2D cameras to inspect surface defects and assembly errors visually. | Measures precise 3D dimensions using laser scanners or coordinate measuring machines (CMM). |

| Primary Use | Quality control in high-speed production lines for defect detection. | Dimensional accuracy verification and reverse engineering. |

| Measurement Type | 2D image analysis. | 3D geometric measurements. |

| Accuracy | Moderate - suitable for visual defect identification. | High - micron-level precision. |

| Speed | Fast, suitable for real-time inspection. | Slower, better for detailed analysis. |

| Cost | Lower initial investment. | Higher cost due to advanced sensors and software. |

| Data Output | Pass/fail classification, defect location. | Detailed 3D point cloud data, dimensional reports. |

| Applications | PCB inspection, label verification, surface flaw detection. | Tool calibration, aerospace component measurement, automotive part inspection. |

| Integration | Easily integrates into existing production lines. | Requires specialized setups and operator expertise. |

Which is better?

Machine vision inspection excels in high-speed identification of surface defects and assembly errors, using 2D image analysis for quality control in manufacturing lines. 3D metrology provides precise dimensional measurements and geometric data by capturing spatial coordinates, essential for verifying complex parts against CAD models. The choice depends on manufacturing needs: machine vision is better for quick surface inspections, while 3D metrology is superior for detailed dimensional accuracy and complex part verification.

Connection

Machine vision inspection enhances manufacturing quality control by using cameras and image processing to detect defects and ensure product consistency. 3D metrology complements this process by providing precise three-dimensional measurements of components, enabling detailed dimensional analysis and verification against design specifications. Integration of machine vision inspection with 3D metrology systems results in improved accuracy, faster defect detection, and optimized production workflow.

Key Terms

**3D Metrology:**

3D metrology provides precise measurement of object geometries using laser scanners, structured light, or coordinate measuring machines (CMM), ensuring high accuracy in quality control processes across automotive and aerospace industries. This technique captures comprehensive spatial data to detect dimensional deviations and surface defects, outperforming traditional 2D inspection methods in complex component analysis. Discover how integrating 3D metrology enhances production efficiency and product reliability.

Coordinate Measuring Machine (CMM)

Coordinate Measuring Machines (CMM) provide highly accurate 3D metrology data by precisely capturing geometric dimensions and tolerances through tactile or non-contact probes. Machine vision inspection excels in high-speed, non-contact optical assessments for surface defects, pattern recognition, and part alignment but typically lacks the dimensional precision of CMM systems. Explore the detailed advantages and applications of CMM versus machine vision inspection to optimize your quality control processes.

Point Cloud

Point cloud data is central to 3D metrology, capturing precise spatial coordinates that enable detailed dimensional analysis and surface inspection. Machine vision inspection typically relies on 2D images or depth maps, which may lack the rich geometric information found in point clouds, limiting accuracy in complex object evaluation. Explore how leveraging point clouds can enhance accuracy and efficiency in industrial quality control.

Source and External Links

What is 3D Metrology? - 3D metrology is the scientific study of precise measurements in three dimensions to obtain exact geometrical data of an object along the x, y, and z axes, often using coordinate measuring machines or 3D scanning systems for applications like quality inspection and reverse engineering.

What is 3D Metrology? And Other Things You Should Know ... - ZEISS - 3D metrology involves physical measurement technologies such as tactile CMMs, structured light scanners, and CT scanners that create detailed 3D representations for quality control, with advances enabling faster, more accurate scanning and integration with CAD software.

3D scanning for metrology - Artec 3D - 3D metrology solutions provide precise 3D measurements of parts' surfaces, evolving from manual tools to coordinate measuring machines and 3D scanners, which offer non-contact scanning beneficial for complex or delicate objects where contact probes may cause damage or miss details.

dowidth.com

dowidth.com