Mass customization enables manufacturers to produce personalized products at near mass production efficiency by integrating advanced technologies like CAD and modular design. Flexible manufacturing systems (FMS) allow rapid adaptation to varying product types and volumes through automated machinery and reprogrammable controls. Explore how these approaches revolutionize production efficiency and customer satisfaction in modern manufacturing.

Why it is important

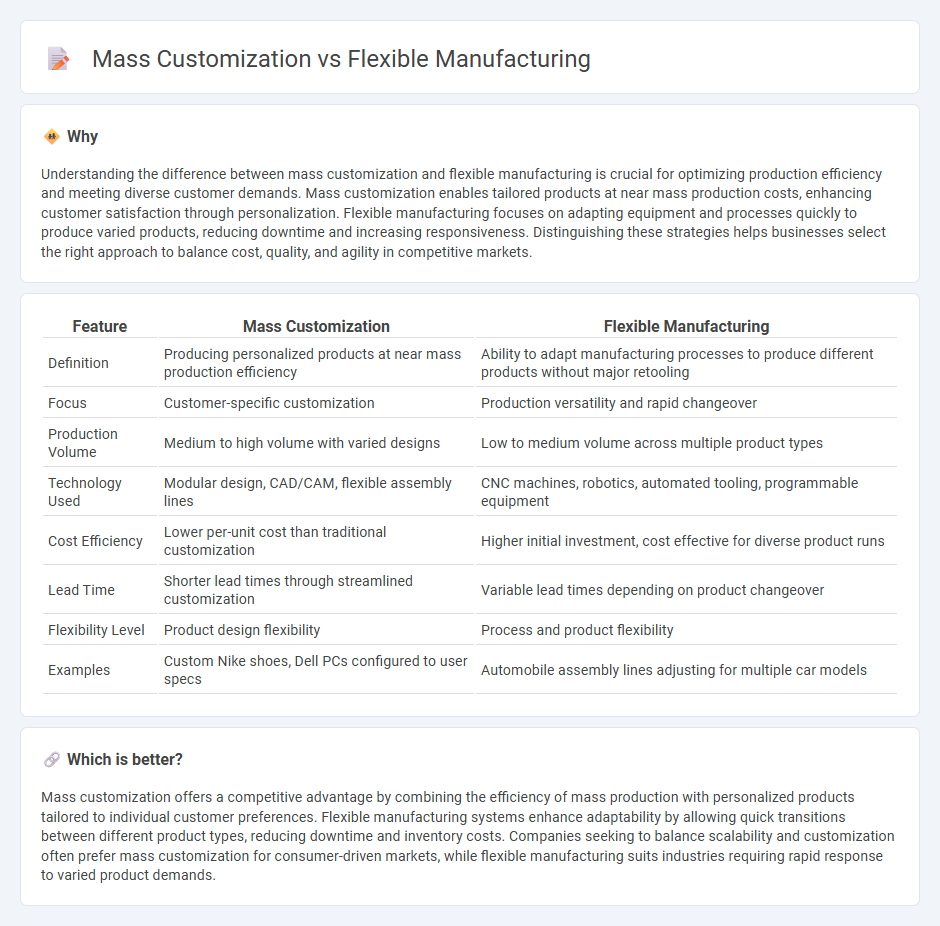

Understanding the difference between mass customization and flexible manufacturing is crucial for optimizing production efficiency and meeting diverse customer demands. Mass customization enables tailored products at near mass production costs, enhancing customer satisfaction through personalization. Flexible manufacturing focuses on adapting equipment and processes quickly to produce varied products, reducing downtime and increasing responsiveness. Distinguishing these strategies helps businesses select the right approach to balance cost, quality, and agility in competitive markets.

Comparison Table

| Feature | Mass Customization | Flexible Manufacturing |

|---|---|---|

| Definition | Producing personalized products at near mass production efficiency | Ability to adapt manufacturing processes to produce different products without major retooling |

| Focus | Customer-specific customization | Production versatility and rapid changeover |

| Production Volume | Medium to high volume with varied designs | Low to medium volume across multiple product types |

| Technology Used | Modular design, CAD/CAM, flexible assembly lines | CNC machines, robotics, automated tooling, programmable equipment |

| Cost Efficiency | Lower per-unit cost than traditional customization | Higher initial investment, cost effective for diverse product runs |

| Lead Time | Shorter lead times through streamlined customization | Variable lead times depending on product changeover |

| Flexibility Level | Product design flexibility | Process and product flexibility |

| Examples | Custom Nike shoes, Dell PCs configured to user specs | Automobile assembly lines adjusting for multiple car models |

Which is better?

Mass customization offers a competitive advantage by combining the efficiency of mass production with personalized products tailored to individual customer preferences. Flexible manufacturing systems enhance adaptability by allowing quick transitions between different product types, reducing downtime and inventory costs. Companies seeking to balance scalability and customization often prefer mass customization for consumer-driven markets, while flexible manufacturing suits industries requiring rapid response to varied product demands.

Connection

Mass customization leverages flexible manufacturing systems to efficiently produce personalized products at scale, enabling rapid adjustments in production processes without sacrificing cost or speed. Flexible manufacturing uses adaptable machinery and workflows that respond to diverse customer specifications, facilitating the seamless integration of custom features. This synergy enhances manufacturing agility, reduces lead times, and aligns product variety with individual consumer demands.

Key Terms

Automation

Flexible manufacturing integrates advanced automation technologies such as CNC machines and robotic systems to rapidly switch production lines, enabling efficient handling of varying product designs without extensive downtime. Mass customization leverages automation for scalable personalization, combining modular design and automated assembly to produce tailored products at near mass production speeds. Explore how automation transforms manufacturing strategies to meet evolving market demands.

Product Variety

Flexible manufacturing systems (FMS) excel in producing a wide range of products with quick changeovers and minimal downtime, enhancing product variety without sacrificing efficiency. Mass customization leverages flexible manufacturing alongside customer input to deliver personalized products on a large scale, blending individuality with mass production. Explore how integrating these strategies can maximize product variety and meet diverse market demands.

Production Scalability

Flexible manufacturing enhances production scalability by enabling rapid adaptation to varying product types and volumes through modular equipment and reprogrammable systems. Mass customization focuses on delivering personalized products at near mass production efficiency, utilizing advanced technologies like AI-driven design and automated assembly lines to maintain high output with individualized features. Explore how these strategies impact scalability in modern manufacturing for deeper insights.

Source and External Links

Flexible manufacturing system - A flexible manufacturing system (FMS) is a production system with routing and machine flexibility that allows adaptation to changes in product type or volume, enhancing efficiency, reducing costs, and improving quality by integrating automated CNC machines, material handling, and central control computers.

Flexible Manufacturing Systems (FMS) | What is ... - FMS involves computer-controlled setups enabling a facility to rearrange production sequences or shift tasks between machines to adapt to supply disruptions or maintenance, with various types including dedicated, sequential, engineered, random, and modular systems for different production needs.

Flexible manufacturing - Flexible manufacturing aims to produce highly varied products with automation, smart robotics, and software working seamlessly, enabling one-off product costs equivalent to mass production while minimizing errors and downtime during quick product changes.

dowidth.com

dowidth.com