The industrial metaverse integrates virtual reality, digital twins, and AI to revolutionize manufacturing processes, creating immersive simulations for optimized production and maintenance. Automation focuses on deploying robotics and programmable systems to enhance efficiency, reduce errors, and lower human intervention in factories. Explore how these cutting-edge technologies transform the future of manufacturing.

Why it is important

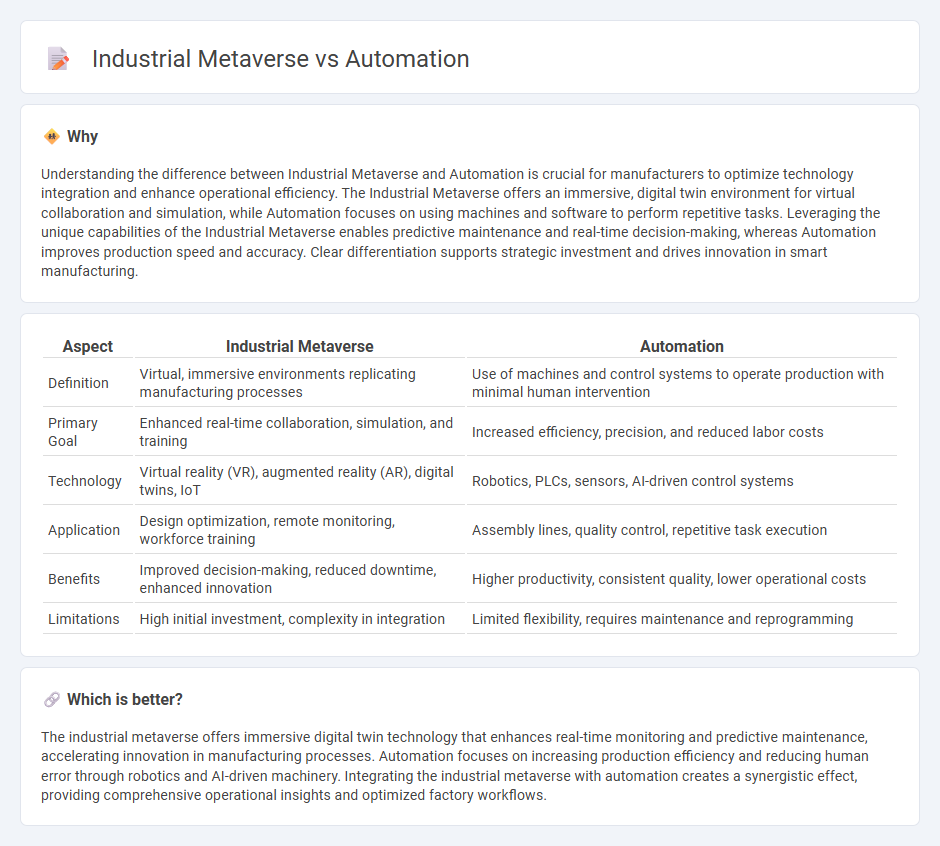

Understanding the difference between Industrial Metaverse and Automation is crucial for manufacturers to optimize technology integration and enhance operational efficiency. The Industrial Metaverse offers an immersive, digital twin environment for virtual collaboration and simulation, while Automation focuses on using machines and software to perform repetitive tasks. Leveraging the unique capabilities of the Industrial Metaverse enables predictive maintenance and real-time decision-making, whereas Automation improves production speed and accuracy. Clear differentiation supports strategic investment and drives innovation in smart manufacturing.

Comparison Table

| Aspect | Industrial Metaverse | Automation |

|---|---|---|

| Definition | Virtual, immersive environments replicating manufacturing processes | Use of machines and control systems to operate production with minimal human intervention |

| Primary Goal | Enhanced real-time collaboration, simulation, and training | Increased efficiency, precision, and reduced labor costs |

| Technology | Virtual reality (VR), augmented reality (AR), digital twins, IoT | Robotics, PLCs, sensors, AI-driven control systems |

| Application | Design optimization, remote monitoring, workforce training | Assembly lines, quality control, repetitive task execution |

| Benefits | Improved decision-making, reduced downtime, enhanced innovation | Higher productivity, consistent quality, lower operational costs |

| Limitations | High initial investment, complexity in integration | Limited flexibility, requires maintenance and reprogramming |

Which is better?

The industrial metaverse offers immersive digital twin technology that enhances real-time monitoring and predictive maintenance, accelerating innovation in manufacturing processes. Automation focuses on increasing production efficiency and reducing human error through robotics and AI-driven machinery. Integrating the industrial metaverse with automation creates a synergistic effect, providing comprehensive operational insights and optimized factory workflows.

Connection

Industrial metaverse integrates virtual reality, digital twins, and advanced simulations to enhance manufacturing processes by enabling real-time monitoring, predictive maintenance, and remote collaboration. Automation in manufacturing leverages robotics, AI, and IoT systems that seamlessly connect with the industrial metaverse to optimize production efficiency, reduce downtime, and improve quality control. This interconnected ecosystem facilitates data-driven decision-making and accelerates innovation in smart factories.

Key Terms

Robotics

Robotics in automation streamlines manufacturing through programmable machines performing repetitive tasks, enhancing efficiency and precision. The industrial metaverse integrates robotics with digital twins, augmented reality, and AI-driven simulations for real-time monitoring and predictive maintenance. Explore how advanced robotics within the industrial metaverse revolutionizes operational capabilities and innovation.

Digital Twin

Digital Twin technology bridges automation and the Industrial Metaverse by creating real-time virtual replicas of physical assets, enhancing operational efficiency and predictive maintenance. In industrial automation, Digital Twins enable precise monitoring and control of machinery, while the Industrial Metaverse expands this concept into immersive, interactive environments for simulation and collaboration. Explore the future of manufacturing through the transformative potential of Digital Twins in industrial ecosystems.

Cyber-Physical Systems

Cyber-Physical Systems (CPS) serve as the backbone of both automation and the industrial metaverse, integrating physical processes with computational intelligence for enhanced operational control. While automation emphasizes real-time process optimization through sensors and actuators, the industrial metaverse extends this by creating immersive digital twins that enable remote monitoring, simulation, and collaborative decision-making. Explore the transformative impact of CPS on industrial innovation by delving deeper into their roles and applications.

Source and External Links

Automation - Wikipedia - Automation involves technologies that reduce human intervention in processes by predetermining decision criteria and embodying them in machines.

What Is Automation? - IBM - Automation applies technology to achieve outcomes with minimal human input, enhancing productivity across various industries.

Understanding Automation - Red Hat - Automation uses technology to perform tasks with reduced human assistance, prevalent in industries like manufacturing and IT.

dowidth.com

dowidth.com