Digital thread integrates data flow across the entire manufacturing lifecycle, enabling real-time visibility and traceability of products from design to delivery. Value stream mapping visualizes and analyzes production processes to identify waste and optimize efficiency, focusing on process improvements within the value chain. Explore how combining digital thread and value stream mapping transforms manufacturing operations for enhanced productivity and product quality.

Why it is important

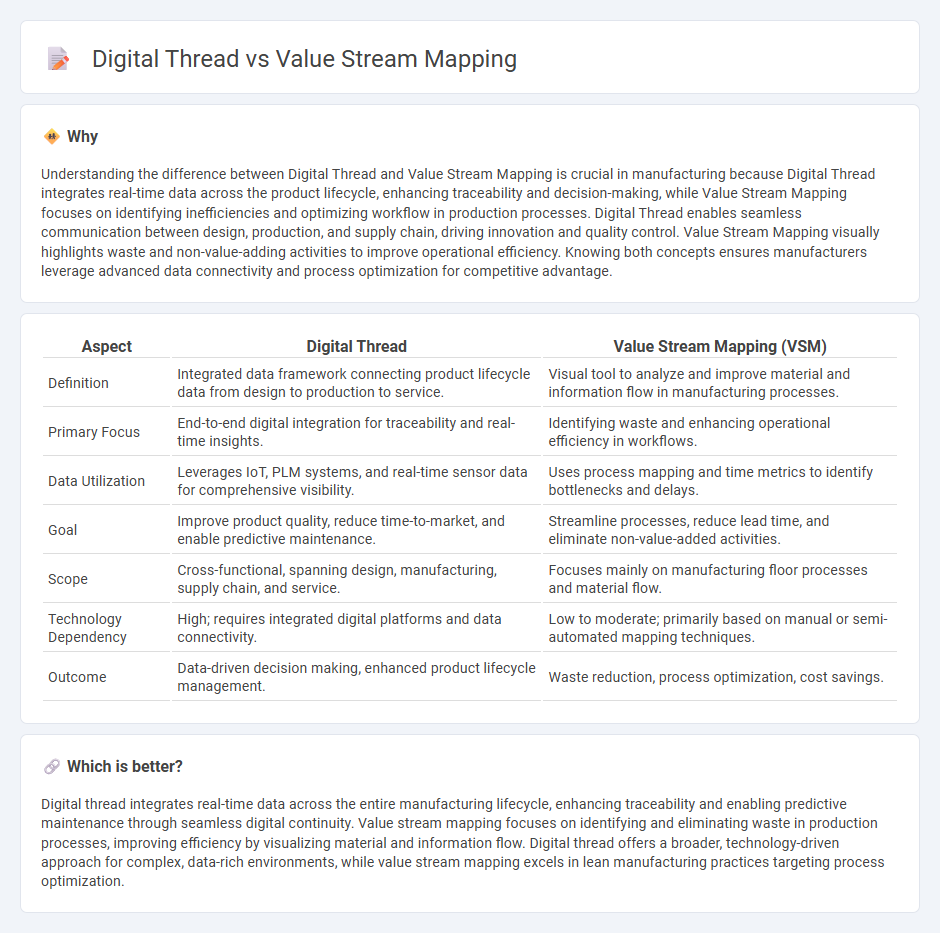

Understanding the difference between Digital Thread and Value Stream Mapping is crucial in manufacturing because Digital Thread integrates real-time data across the product lifecycle, enhancing traceability and decision-making, while Value Stream Mapping focuses on identifying inefficiencies and optimizing workflow in production processes. Digital Thread enables seamless communication between design, production, and supply chain, driving innovation and quality control. Value Stream Mapping visually highlights waste and non-value-adding activities to improve operational efficiency. Knowing both concepts ensures manufacturers leverage advanced data connectivity and process optimization for competitive advantage.

Comparison Table

| Aspect | Digital Thread | Value Stream Mapping (VSM) |

|---|---|---|

| Definition | Integrated data framework connecting product lifecycle data from design to production to service. | Visual tool to analyze and improve material and information flow in manufacturing processes. |

| Primary Focus | End-to-end digital integration for traceability and real-time insights. | Identifying waste and enhancing operational efficiency in workflows. |

| Data Utilization | Leverages IoT, PLM systems, and real-time sensor data for comprehensive visibility. | Uses process mapping and time metrics to identify bottlenecks and delays. |

| Goal | Improve product quality, reduce time-to-market, and enable predictive maintenance. | Streamline processes, reduce lead time, and eliminate non-value-added activities. |

| Scope | Cross-functional, spanning design, manufacturing, supply chain, and service. | Focuses mainly on manufacturing floor processes and material flow. |

| Technology Dependency | High; requires integrated digital platforms and data connectivity. | Low to moderate; primarily based on manual or semi-automated mapping techniques. |

| Outcome | Data-driven decision making, enhanced product lifecycle management. | Waste reduction, process optimization, cost savings. |

Which is better?

Digital thread integrates real-time data across the entire manufacturing lifecycle, enhancing traceability and enabling predictive maintenance through seamless digital continuity. Value stream mapping focuses on identifying and eliminating waste in production processes, improving efficiency by visualizing material and information flow. Digital thread offers a broader, technology-driven approach for complex, data-rich environments, while value stream mapping excels in lean manufacturing practices targeting process optimization.

Connection

Digital thread integrates data flow across the entire manufacturing process, enabling real-time visibility and traceability from design to production. Value stream mapping visually represents these processes, identifying waste and bottlenecks to improve efficiency. Together, digital thread data enhances value stream mapping accuracy, driving continuous optimization in manufacturing operations.

Key Terms

**Value stream mapping:**

Value stream mapping (VSM) is a lean-management method used to analyze and design the flow of materials and information required to bring a product or service to a customer, focusing on identifying waste and improving efficiency across processes. Unlike the digital thread, which integrates data across the product lifecycle digitally, VSM emphasizes visualizing processes and pinpointing bottlenecks to enhance value delivery in manufacturing or service systems. Explore how value stream mapping can optimize your operational workflow for improved productivity and reduced lead times.

Process flow

Value stream mapping visualizes the end-to-end process flow by identifying waste and inefficiencies to optimize production cycles, focusing on lean manufacturing principles. The digital thread integrates data across the product lifecycle, creating a continuous, digital process flow that enables real-time tracking and decision-making through interconnected systems. Explore how combining value stream mapping and the digital thread can revolutionize your process flow optimization strategy.

Waste identification

Value stream mapping highlights waste identification by visualizing processes, material flows, and information flows to pinpoint inefficiencies in production cycles. The digital thread integrates real-time data across the product lifecycle, enabling continuous monitoring and early detection of waste through digital traceability. Explore deeper insights into how these methodologies optimize manufacturing waste reduction strategies.

Source and External Links

Value-stream mapping - Wikipedia - Value-stream mapping (VSM) is a lean-management method that visually maps all critical steps in a process to analyze and design material and information flows, aiming to identify and remove waste and improve efficiency across industries like manufacturing, healthcare, and software development.

Value Stream Mapping Overview - Lean Enterprise Institute - VSM involves diagramming every step in the flow of materials and information from order to delivery, starting with a current state map and then creating a future state map to visualize improvements and eliminate waste, originally developed as part of the Toyota Production System.

What is Value Stream Mapping | Lucidchart - Value stream mapping is a flowchart method used to analyze and improve all actions in delivering a product or service by distinguishing value-added steps from waste, enabling teams to create efficient, integrated systems through current, future, and ideal state maps.

dowidth.com

dowidth.com