Manufacturing is rapidly evolving with two significant trends: servitization, which integrates services with product offerings to enhance customer value, and reshoring, the strategic relocation of production closer to home markets to improve supply chain resilience and reduce costs. Companies embracing servitization achieve increased revenue streams through maintenance, consulting, and customization services, while reshoring addresses geopolitical risks and rising labor expenses abroad. Explore these transformative strategies to understand how modern manufacturers optimize competitiveness and operational efficiency.

Why it is important

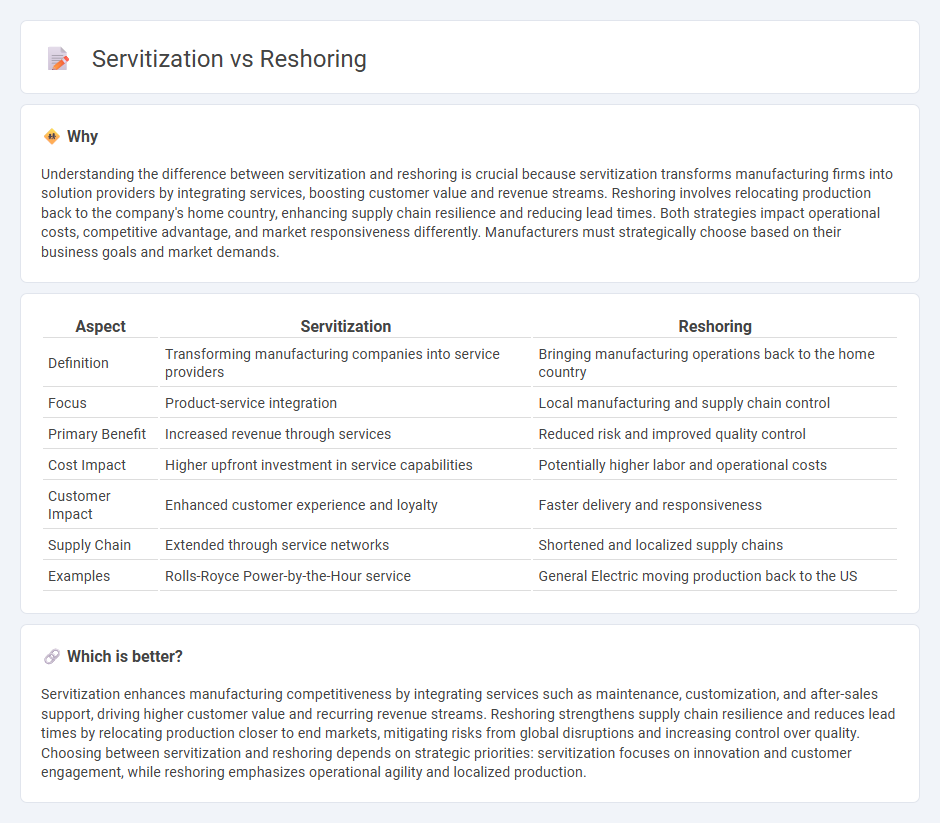

Understanding the difference between servitization and reshoring is crucial because servitization transforms manufacturing firms into solution providers by integrating services, boosting customer value and revenue streams. Reshoring involves relocating production back to the company's home country, enhancing supply chain resilience and reducing lead times. Both strategies impact operational costs, competitive advantage, and market responsiveness differently. Manufacturers must strategically choose based on their business goals and market demands.

Comparison Table

| Aspect | Servitization | Reshoring |

|---|---|---|

| Definition | Transforming manufacturing companies into service providers | Bringing manufacturing operations back to the home country |

| Focus | Product-service integration | Local manufacturing and supply chain control |

| Primary Benefit | Increased revenue through services | Reduced risk and improved quality control |

| Cost Impact | Higher upfront investment in service capabilities | Potentially higher labor and operational costs |

| Customer Impact | Enhanced customer experience and loyalty | Faster delivery and responsiveness |

| Supply Chain | Extended through service networks | Shortened and localized supply chains |

| Examples | Rolls-Royce Power-by-the-Hour service | General Electric moving production back to the US |

Which is better?

Servitization enhances manufacturing competitiveness by integrating services such as maintenance, customization, and after-sales support, driving higher customer value and recurring revenue streams. Reshoring strengthens supply chain resilience and reduces lead times by relocating production closer to end markets, mitigating risks from global disruptions and increasing control over quality. Choosing between servitization and reshoring depends on strategic priorities: servitization focuses on innovation and customer engagement, while reshoring emphasizes operational agility and localized production.

Connection

Servitization transforms manufacturing businesses by integrating services with product offerings, enhancing customer value and operational flexibility. Reshoring supports this shift by bringing production closer to end markets, enabling faster service delivery and improved supply chain responsiveness. Together, servitization and reshoring create a competitive advantage through localized, service-oriented manufacturing models.

Key Terms

Supply Chain Localization

Reshoring involves relocating manufacturing operations closer to the end market to enhance supply chain localization, reducing lead times and transportation costs while improving responsiveness. Servitization transforms traditional product-centric businesses into service-oriented models, emphasizing after-sales services and customer support, which further localizes supply chain interactions by fostering closer supplier and client relationships. Explore detailed strategies to optimize supply chain localization through reshoring and servitization to boost operational efficiency and customer satisfaction.

Product-Service Systems

Reshoring involves relocating manufacturing processes closer to the home market to enhance control, reduce lead times, and improve responsiveness, while servitization transforms traditional product offerings into integrated Product-Service Systems (PSS) that combine products and services for added value. Product-Service Systems optimize customer experience by delivering tailored solutions, increasing operational efficiency through service innovation, and fostering sustainable competitive advantage in reshoring strategies. Explore how integrating reshoring with servitization can drive growth and resilience in manufacturing ecosystems.

Total Cost of Ownership

Reshoring manufacturing operations can significantly reduce the Total Cost of Ownership (TCO) by minimizing logistics expenses, tariffs, and lead times, while servitization enhances value by transforming products into service offerings that optimize operational costs and customer satisfaction. Combining reshoring with servitization strategies offers businesses a competitive advantage through increased control over supply chains and stronger customer relationships, leading to a more efficient and cost-effective business model. Explore how integrating reshoring and servitization can strategically impact your company's TCO and profitability.

Source and External Links

Reshoring - SCRG - Reshoring is the process of bringing manufacturing operations back from a foreign country to a business's home country, aiming to regain control over quality, lead time, intellectual property, and supply chain visibility while reducing risks associated with foreign production.

What is Reshoring? - Reshoring is the practice of bringing manufacturing and services back to the U.S. from overseas to strengthen the economy by creating well-paying jobs, reducing trade deficits, and improving total product cost and innovation effectiveness.

Offshoring vs reshoring - The Rodon Group - Reshoring offers benefits like more American jobs, lower delivery costs, shorter lead times, higher product quality, and better customer perception, but can face challenges such as higher labor and relocation costs.

dowidth.com

dowidth.com