Industrial edge computing enhances manufacturing processes by processing data near the source, reducing latency and enabling real-time decision-making on the factory floor. Machine vision systems capture and analyze visual information to automate quality control, defect detection, and assembly verification. Explore how integrating these technologies can revolutionize industrial efficiency and precision.

Why it is important

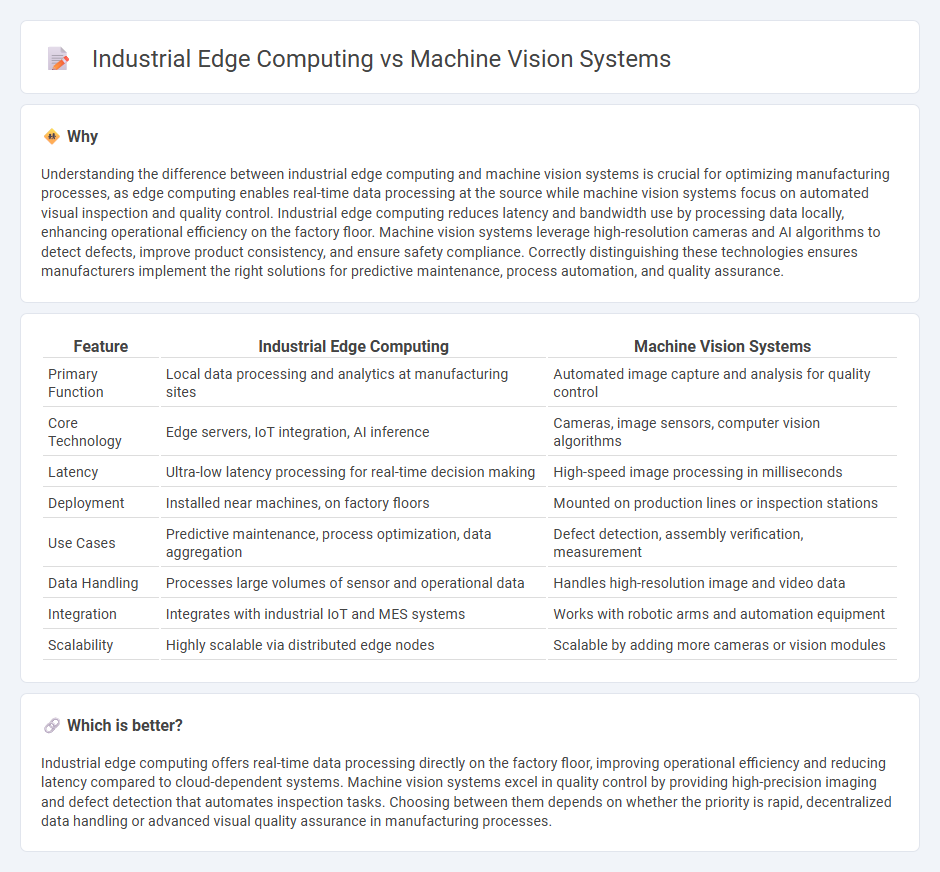

Understanding the difference between industrial edge computing and machine vision systems is crucial for optimizing manufacturing processes, as edge computing enables real-time data processing at the source while machine vision systems focus on automated visual inspection and quality control. Industrial edge computing reduces latency and bandwidth use by processing data locally, enhancing operational efficiency on the factory floor. Machine vision systems leverage high-resolution cameras and AI algorithms to detect defects, improve product consistency, and ensure safety compliance. Correctly distinguishing these technologies ensures manufacturers implement the right solutions for predictive maintenance, process automation, and quality assurance.

Comparison Table

| Feature | Industrial Edge Computing | Machine Vision Systems |

|---|---|---|

| Primary Function | Local data processing and analytics at manufacturing sites | Automated image capture and analysis for quality control |

| Core Technology | Edge servers, IoT integration, AI inference | Cameras, image sensors, computer vision algorithms |

| Latency | Ultra-low latency processing for real-time decision making | High-speed image processing in milliseconds |

| Deployment | Installed near machines, on factory floors | Mounted on production lines or inspection stations |

| Use Cases | Predictive maintenance, process optimization, data aggregation | Defect detection, assembly verification, measurement |

| Data Handling | Processes large volumes of sensor and operational data | Handles high-resolution image and video data |

| Integration | Integrates with industrial IoT and MES systems | Works with robotic arms and automation equipment |

| Scalability | Highly scalable via distributed edge nodes | Scalable by adding more cameras or vision modules |

Which is better?

Industrial edge computing offers real-time data processing directly on the factory floor, improving operational efficiency and reducing latency compared to cloud-dependent systems. Machine vision systems excel in quality control by providing high-precision imaging and defect detection that automates inspection tasks. Choosing between them depends on whether the priority is rapid, decentralized data handling or advanced visual quality assurance in manufacturing processes.

Connection

Industrial edge computing enhances machine vision systems by processing visual data locally on manufacturing floors, reducing latency and improving real-time decision-making. This integration enables faster defect detection, quality control, and predictive maintenance in automated production lines. Combining edge computing with machine vision optimizes operational efficiency and reduces reliance on cloud connectivity.

Key Terms

Image Processing Algorithms

Machine vision systems rely heavily on advanced image processing algorithms to analyze visual data in real-time for quality inspection and automation tasks. Industrial edge computing enhances this capability by processing image data locally, reducing latency and bandwidth usage while improving decision-making speed. Explore the integration of image processing algorithms in edge-enabled machine vision systems to boost industrial efficiency.

Real-time Data Analysis

Machine vision systems generate high-resolution visual data essential for quality control and defect detection in manufacturing, requiring rapid processing to maintain production efficiency. Industrial edge computing processes this data locally at the source, reducing latency and enabling real-time anomaly detection and decision-making without reliance on cloud connectivity. Explore how integrating machine vision with edge computing optimizes real-time data analysis for smarter industrial operations.

Edge Devices

Machine vision systems rely on high-resolution cameras and advanced image processing algorithms to enable real-time defect detection and quality control on manufacturing lines, demanding low-latency computing at the source. Industrial edge computing enhances these systems by integrating powerful edge devices equipped with AI accelerators and robust connectivity, ensuring rapid data analysis and minimal cloud dependency for critical decision-making. Explore how cutting-edge edge devices are transforming machine vision applications in industrial environments.

Source and External Links

Machine Vision - Keyence - Machine vision systems use diverse sensors like 3D cameras and AI-driven software to capture, process, and interpret images for tasks such as object recognition and scene analysis, with categories including 1D, 2D, 3D, and spectral/color vision systems.

Machine Vision Manufacturers | Machine Vision Systems - Advanced machine vision employs neural networks and deep learning for continuous system learning, enhances pattern recognition and OCR capabilities, and enables precise barcode reading for tasks like defect detection, sorting, and traceability.

Machine Vision 101 - Teledyne Vision Solutions - Machine vision combines sensors, processing hardware, and software to perform 100% online inspection, improving product quality, yield, and reducing costs through accurate and consistent visual inspection and guidance in manufacturing.

dowidth.com

dowidth.com