Factory as a Service (FaaS) offers on-demand, scalable manufacturing resources through cloud-based platforms, enabling businesses to access flexible production capabilities without owning physical facilities. Contract manufacturing involves outsourcing production to third-party manufacturers who handle the entire manufacturing process based on agreed specifications and volume commitments. Explore how these models can optimize your supply chain and manufacturing efficiency.

Why it is important

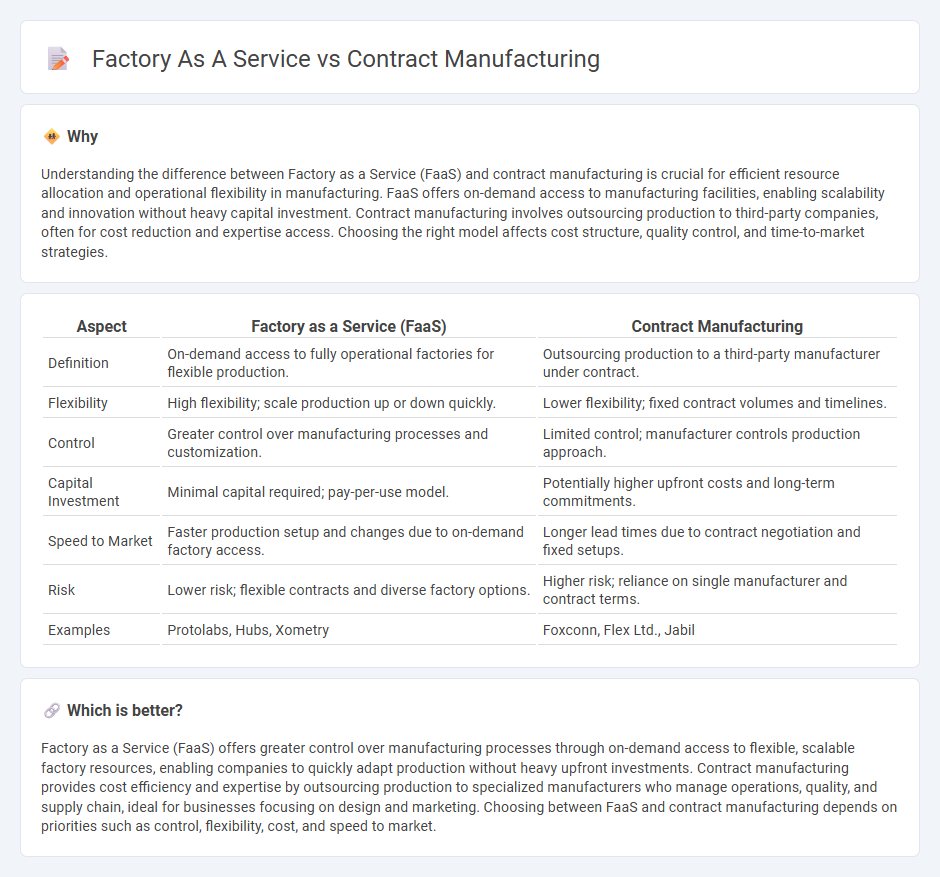

Understanding the difference between Factory as a Service (FaaS) and contract manufacturing is crucial for efficient resource allocation and operational flexibility in manufacturing. FaaS offers on-demand access to manufacturing facilities, enabling scalability and innovation without heavy capital investment. Contract manufacturing involves outsourcing production to third-party companies, often for cost reduction and expertise access. Choosing the right model affects cost structure, quality control, and time-to-market strategies.

Comparison Table

| Aspect | Factory as a Service (FaaS) | Contract Manufacturing |

|---|---|---|

| Definition | On-demand access to fully operational factories for flexible production. | Outsourcing production to a third-party manufacturer under contract. |

| Flexibility | High flexibility; scale production up or down quickly. | Lower flexibility; fixed contract volumes and timelines. |

| Control | Greater control over manufacturing processes and customization. | Limited control; manufacturer controls production approach. |

| Capital Investment | Minimal capital required; pay-per-use model. | Potentially higher upfront costs and long-term commitments. |

| Speed to Market | Faster production setup and changes due to on-demand factory access. | Longer lead times due to contract negotiation and fixed setups. |

| Risk | Lower risk; flexible contracts and diverse factory options. | Higher risk; reliance on single manufacturer and contract terms. |

| Examples | Protolabs, Hubs, Xometry | Foxconn, Flex Ltd., Jabil |

Which is better?

Factory as a Service (FaaS) offers greater control over manufacturing processes through on-demand access to flexible, scalable factory resources, enabling companies to quickly adapt production without heavy upfront investments. Contract manufacturing provides cost efficiency and expertise by outsourcing production to specialized manufacturers who manage operations, quality, and supply chain, ideal for businesses focusing on design and marketing. Choosing between FaaS and contract manufacturing depends on priorities such as control, flexibility, cost, and speed to market.

Connection

Factory as a Service (FaaS) and contract manufacturing both streamline production processes by leveraging third-party facilities and expertise to optimize efficiency and cost-effectiveness. FaaS offers scalable, on-demand manufacturing resources that integrate advanced technologies like IoT and automation, enabling contract manufacturers to deliver customized products with faster turnaround times. This synergy allows companies to reduce capital investment and improve supply chain agility while maintaining high-quality standards.

Key Terms

Outsourcing

Contract manufacturing involves outsourcing production to specialized third-party manufacturers to reduce costs and leverage expertise, while Factory as a Service (FaaS) provides flexible, on-demand access to manufacturing capacity through digital platforms without long-term commitments. Outsourcing with contract manufacturing centralizes quality control and intellectual property management, whereas FaaS emphasizes agility and scalability for rapid prototyping and small-batch production. Discover more about how these outsourcing models transform modern manufacturing strategies and optimize supply chains.

Flexibility

Contract manufacturing offers tailored production with flexible scaling options, allowing businesses to adjust output based on demand fluctuations without investing in fixed assets. Factory as a Service (FaaS) provides on-demand access to advanced manufacturing facilities and technology, enabling rapid reconfiguration and customization to meet evolving market needs. Explore how each model can enhance your operational flexibility and drive competitive advantage.

Asset-Light

Contract manufacturing leverages third-party facilities to produce goods, minimizing capital investment and maintaining an asset-light approach. Factory as a Service (FaaS) combines on-demand manufacturing with flexible access to advanced equipment, further reducing the need for heavy asset ownership. Explore how these models optimize production efficiency while preserving operational agility.

Source and External Links

Overview of Contract Manufacturing - Oracle Help Center - Contract manufacturing is a business process where the original equipment manufacturer (OEM) outsources production of specific parts or full products to a contract manufacturer who builds to exact OEM specifications, allowing OEMs to completely outsource their manufacturing while tracking inventory and production in real time.

What is OEM vs Contract Manufacturing? - Komaspec - In contract manufacturing, the client provides designs and specifications, retains IP rights, and contracts a manufacturer to produce products or assemblies based on those specifications, often used for custom or niche products without existing OEM tooling.

Top Contract Manufacturing Companies | Service Providers - Contract manufacturing companies provide services such as CNC machining, assembly, finishing, testing, prototyping, and large or small volume production across diverse industries, evolving since the 1970s to include advanced manufacturing technologies and supply chain support.

dowidth.com

dowidth.com