Green steel production leverages renewable energy sources and carbon capture technologies to significantly reduce CO2 emissions compared to conventional processes, making it a promising solution for sustainable manufacturing. Secondary steel, recycled from scrap metal, offers a lower environmental footprint by minimizing raw material extraction and energy consumption during production. Explore the benefits and challenges of green steel versus secondary steel to understand their impact on the future of eco-friendly manufacturing.

Why it is important

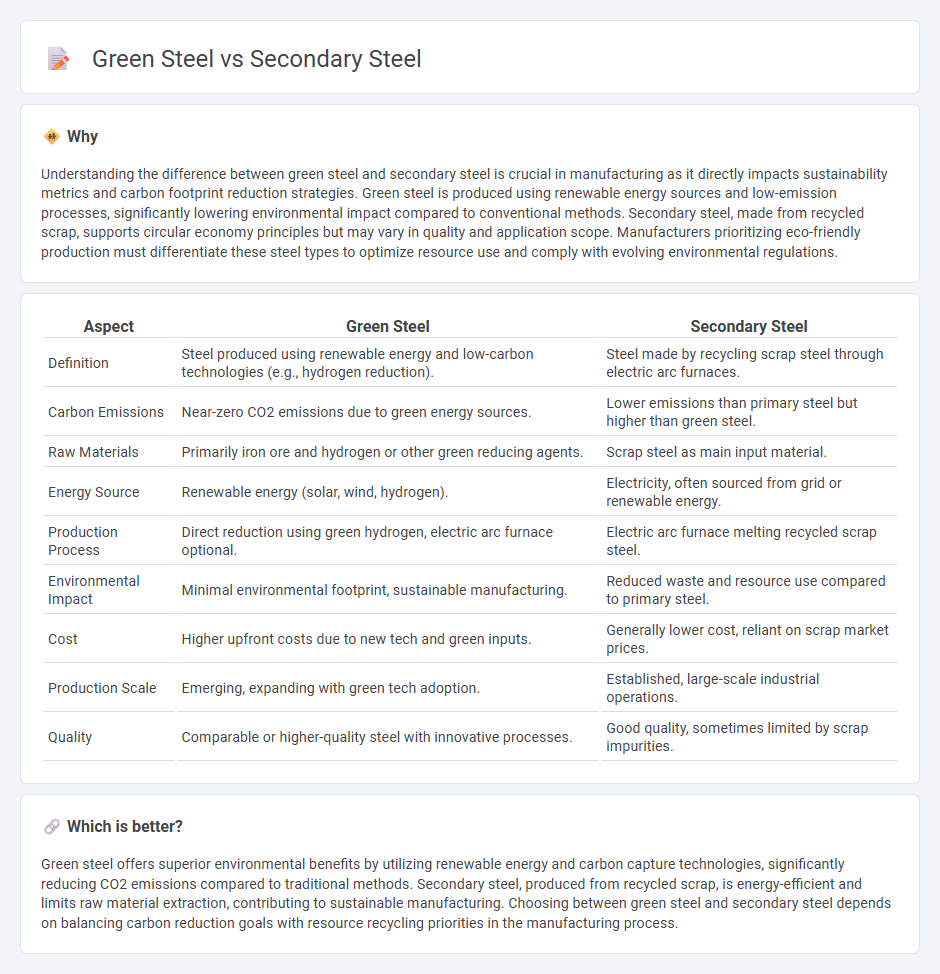

Understanding the difference between green steel and secondary steel is crucial in manufacturing as it directly impacts sustainability metrics and carbon footprint reduction strategies. Green steel is produced using renewable energy sources and low-emission processes, significantly lowering environmental impact compared to conventional methods. Secondary steel, made from recycled scrap, supports circular economy principles but may vary in quality and application scope. Manufacturers prioritizing eco-friendly production must differentiate these steel types to optimize resource use and comply with evolving environmental regulations.

Comparison Table

| Aspect | Green Steel | Secondary Steel |

|---|---|---|

| Definition | Steel produced using renewable energy and low-carbon technologies (e.g., hydrogen reduction). | Steel made by recycling scrap steel through electric arc furnaces. |

| Carbon Emissions | Near-zero CO2 emissions due to green energy sources. | Lower emissions than primary steel but higher than green steel. |

| Raw Materials | Primarily iron ore and hydrogen or other green reducing agents. | Scrap steel as main input material. |

| Energy Source | Renewable energy (solar, wind, hydrogen). | Electricity, often sourced from grid or renewable energy. |

| Production Process | Direct reduction using green hydrogen, electric arc furnace optional. | Electric arc furnace melting recycled scrap steel. |

| Environmental Impact | Minimal environmental footprint, sustainable manufacturing. | Reduced waste and resource use compared to primary steel. |

| Cost | Higher upfront costs due to new tech and green inputs. | Generally lower cost, reliant on scrap market prices. |

| Production Scale | Emerging, expanding with green tech adoption. | Established, large-scale industrial operations. |

| Quality | Comparable or higher-quality steel with innovative processes. | Good quality, sometimes limited by scrap impurities. |

Which is better?

Green steel offers superior environmental benefits by utilizing renewable energy and carbon capture technologies, significantly reducing CO2 emissions compared to traditional methods. Secondary steel, produced from recycled scrap, is energy-efficient and limits raw material extraction, contributing to sustainable manufacturing. Choosing between green steel and secondary steel depends on balancing carbon reduction goals with resource recycling priorities in the manufacturing process.

Connection

Green steel production relies on secondary steel as a key resource to reduce carbon emissions by recycling scrap metal instead of using virgin iron ore. Utilizing secondary steel in electric arc furnaces significantly lowers energy consumption and environmental impact within manufacturing processes. The integration of green steel and secondary steel represents a pivotal advancement toward sustainable steel manufacturing and circular economy principles.

Key Terms

Carbon emissions

Secondary steel production, which involves recycling scrap metal, significantly reduces carbon emissions compared to green steel methods relying on direct reduced iron and hydrogen. While green steel aims for ultimate decarbonization by eliminating fossil fuels, secondary steel currently offers a lower carbon footprint due to energy-efficient electric arc furnaces using recycled materials. Explore how these approaches contribute to sustainable steelmaking and carbon emission reduction.

Recycled materials

Secondary steel primarily relies on recycled scrap metal, significantly reducing the need for raw iron ore and lowering energy consumption compared to green steel, which incorporates innovative methods like hydrogen-based reduction to minimize carbon emissions at the production stage. The recycled content in secondary steel production can reach up to 90%, making it a highly resource-efficient process with substantial environmental benefits. Explore how advancements in recycling technology and green steel innovations are shaping a sustainable future for the steel industry.

Energy source

Secondary steel production primarily uses electric arc furnaces powered by recycled scrap metal, significantly reducing energy consumption compared to primary steelmaking. Green steel focuses on using renewable energy sources such as hydrogen and solar power to minimize carbon emissions throughout the production process. Explore the latest innovations in energy-efficient steel manufacturing to understand their environmental impact.

Source and External Links

Fact sheet 1: Secondary steel - Offshore Wind Scotland - Secondary steel consists of steel elements that fit onto the primary structure, such as platforms, ladders, walkways, railings, and other components enabling access, safety, and protection in structures like wind turbines.

Primary vs Secondary Steelmaking: What's the Difference? - Secondary steelmaking involves electric arc furnaces melting scrap iron to produce steel, differing from primary steelmaking's use of oxygen blowing to convert molten iron.

Structural/primary Steel Vs. Secondary Steel: What's The Difference? - Secondary steel is typically mild steel used to reinforce or support structural steel via smaller components like brackets and braces, offering cost-effectiveness and versatility compared to primary structural steel.

dowidth.com

dowidth.com