Machine vision inspection utilizes high-resolution cameras and advanced algorithms to detect surface defects and ensure dimensional accuracy in manufacturing processes. Ultrasonic testing employs high-frequency sound waves to identify internal flaws and material inconsistencies without damaging the components. Discover more about how these technologies enhance quality control and improve production efficiency.

Why it is important

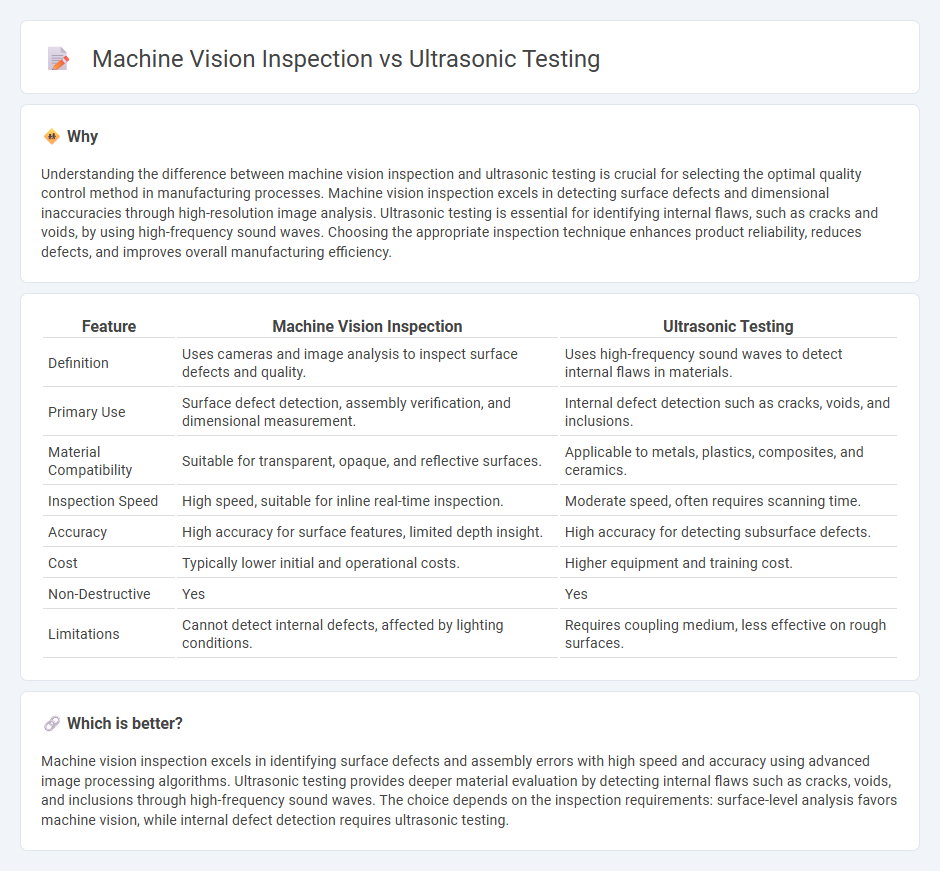

Understanding the difference between machine vision inspection and ultrasonic testing is crucial for selecting the optimal quality control method in manufacturing processes. Machine vision inspection excels in detecting surface defects and dimensional inaccuracies through high-resolution image analysis. Ultrasonic testing is essential for identifying internal flaws, such as cracks and voids, by using high-frequency sound waves. Choosing the appropriate inspection technique enhances product reliability, reduces defects, and improves overall manufacturing efficiency.

Comparison Table

| Feature | Machine Vision Inspection | Ultrasonic Testing |

|---|---|---|

| Definition | Uses cameras and image analysis to inspect surface defects and quality. | Uses high-frequency sound waves to detect internal flaws in materials. |

| Primary Use | Surface defect detection, assembly verification, and dimensional measurement. | Internal defect detection such as cracks, voids, and inclusions. |

| Material Compatibility | Suitable for transparent, opaque, and reflective surfaces. | Applicable to metals, plastics, composites, and ceramics. |

| Inspection Speed | High speed, suitable for inline real-time inspection. | Moderate speed, often requires scanning time. |

| Accuracy | High accuracy for surface features, limited depth insight. | High accuracy for detecting subsurface defects. |

| Cost | Typically lower initial and operational costs. | Higher equipment and training cost. |

| Non-Destructive | Yes | Yes |

| Limitations | Cannot detect internal defects, affected by lighting conditions. | Requires coupling medium, less effective on rough surfaces. |

Which is better?

Machine vision inspection excels in identifying surface defects and assembly errors with high speed and accuracy using advanced image processing algorithms. Ultrasonic testing provides deeper material evaluation by detecting internal flaws such as cracks, voids, and inclusions through high-frequency sound waves. The choice depends on the inspection requirements: surface-level analysis favors machine vision, while internal defect detection requires ultrasonic testing.

Connection

Machine vision inspection and ultrasonic testing are interconnected in manufacturing through their complementary roles in quality control and defect detection. Machine vision uses optical sensors and image processing algorithms to identify surface defects and ensure dimensional accuracy, while ultrasonic testing employs high-frequency sound waves to detect internal flaws and material inconsistencies. Together, these technologies enhance manufacturing reliability by providing comprehensive inspection capabilities for both external and subsurface defects.

Key Terms

**Ultrasonic Testing:**

Ultrasonic testing employs high-frequency sound waves to detect internal flaws and material thickness variations in metals, composites, and welds, offering precise subsurface defect identification beyond surface-level inspection capabilities. Machine vision relies on camera-based systems to analyze surface features, ideal for detecting surface defects but limited in penetrating materials for internal inspection. Explore the unique advantages and applications of ultrasonic testing to enhance your nondestructive evaluation processes.

Transducer

Ultrasonic testing relies on piezoelectric transducers to generate and receive high-frequency sound waves, enabling precise detection of internal flaws in materials. Machine vision inspection employs image sensors and cameras instead of transducers, focusing on surface quality and visual defects. Explore the differences between transducers in ultrasonic testing and sensors in machine vision to optimize your inspection process.

Couplant

Ultrasonic testing relies on a couplant, typically a gel or liquid, to facilitate the transmission of sound waves between the probe and the tested material, ensuring accurate defect detection. Machine vision inspection, in contrast, is a non-contact optical method that does not require a couplant, using cameras and lighting to analyze surface features and dimensions. Explore deeper insights on selecting inspection methods based on couplant requirements and application specificity.

Source and External Links

Ultrasonic testing - Ultrasonic testing (UT) uses high-frequency sound waves, typically between 0.1-15 MHz, to detect internal flaws, measure material thickness, and characterize materials in metals, concrete, wood, and composites.

Basic Principles of Ultrasonic Testing - Ultrasonic testing operates by sending sound energy into a material and analyzing echoes reflected from internal discontinuities to determine flaw location, size, and orientation.

Ultrasonic Testing: Enhancing Industrial Inspections - Common UT methods include pulse-echo, phased array, and pitch-catch, with scan types such as A-scan (thickness), B-scan (cross-section), and C-scan (3D mapping) for detailed material inspection.

dowidth.com

dowidth.com