Industrial edge computing processes data locally near manufacturing equipment, reducing latency and enhancing real-time decision-making in smart factories. Sensor networks collect extensive environmental and operational data but often rely on centralized processing, which can introduce delays and bandwidth limitations. Discover how integrating industrial edge computing with sensor networks revolutionizes manufacturing efficiency and reliability.

Why it is important

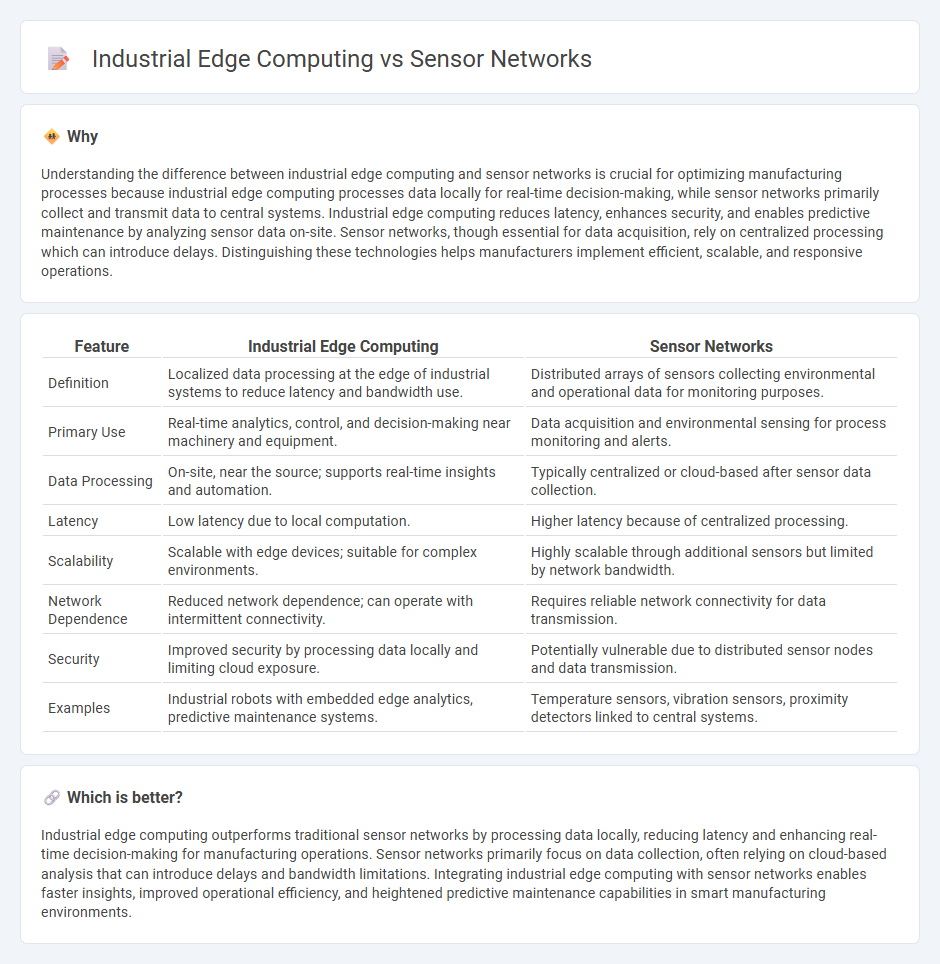

Understanding the difference between industrial edge computing and sensor networks is crucial for optimizing manufacturing processes because industrial edge computing processes data locally for real-time decision-making, while sensor networks primarily collect and transmit data to central systems. Industrial edge computing reduces latency, enhances security, and enables predictive maintenance by analyzing sensor data on-site. Sensor networks, though essential for data acquisition, rely on centralized processing which can introduce delays. Distinguishing these technologies helps manufacturers implement efficient, scalable, and responsive operations.

Comparison Table

| Feature | Industrial Edge Computing | Sensor Networks |

|---|---|---|

| Definition | Localized data processing at the edge of industrial systems to reduce latency and bandwidth use. | Distributed arrays of sensors collecting environmental and operational data for monitoring purposes. |

| Primary Use | Real-time analytics, control, and decision-making near machinery and equipment. | Data acquisition and environmental sensing for process monitoring and alerts. |

| Data Processing | On-site, near the source; supports real-time insights and automation. | Typically centralized or cloud-based after sensor data collection. |

| Latency | Low latency due to local computation. | Higher latency because of centralized processing. |

| Scalability | Scalable with edge devices; suitable for complex environments. | Highly scalable through additional sensors but limited by network bandwidth. |

| Network Dependence | Reduced network dependence; can operate with intermittent connectivity. | Requires reliable network connectivity for data transmission. |

| Security | Improved security by processing data locally and limiting cloud exposure. | Potentially vulnerable due to distributed sensor nodes and data transmission. |

| Examples | Industrial robots with embedded edge analytics, predictive maintenance systems. | Temperature sensors, vibration sensors, proximity detectors linked to central systems. |

Which is better?

Industrial edge computing outperforms traditional sensor networks by processing data locally, reducing latency and enhancing real-time decision-making for manufacturing operations. Sensor networks primarily focus on data collection, often relying on cloud-based analysis that can introduce delays and bandwidth limitations. Integrating industrial edge computing with sensor networks enables faster insights, improved operational efficiency, and heightened predictive maintenance capabilities in smart manufacturing environments.

Connection

Industrial edge computing enhances manufacturing efficiency by processing sensor network data locally, reducing latency and bandwidth usage. Sensor networks collect real-time data from machines and production lines, enabling predictive maintenance and process optimization. Integrating edge computing with these sensor networks ensures rapid decision-making and improved operational reliability in industrial environments.

Key Terms

Data Acquisition

Sensor networks specialize in continuous data acquisition by deploying distributed nodes that capture real-time environmental variables such as temperature, humidity, and pressure. Industrial edge computing enhances this capability by processing and filtering sensor data locally, reducing latency and bandwidth usage before transmitting actionable insights to central systems. Explore the advancements in sensor integration and edge analytics for optimized industrial data acquisition solutions.

Real-time Processing

Sensor networks collect vast amounts of raw data from distributed devices, but often lack the computational power for real-time processing at the source, leading to latency in critical decision-making. Industrial edge computing enhances real-time processing by deploying powerful edge servers close to the data origin, enabling immediate analytics, reduced bandwidth usage, and faster response times for industrial automation. Discover how integrating edge computing with sensor networks revolutionizes real-time data processing and operational efficiency.

Decentralized Control

Sensor networks enable decentralized control by collecting and processing data locally, reducing latency and enhancing real-time decision-making in industrial environments. Industrial edge computing extends this capability by integrating advanced analytics and machine learning at the edge, facilitating autonomous operations and predictive maintenance. Explore how decentralized control through these technologies transforms industrial processes and drives operational efficiency.

Source and External Links

Wireless sensor network - Wireless sensor networks (WSNs) consist of spatially dispersed sensors that monitor environmental conditions like temperature and sound, forwarding data wirelessly to a central location, commonly used in applications ranging from military surveillance to industrial process monitoring.

Sensor Networks - Sensor networks are interconnected sensor systems designed to collect, transmit, and analyze data in contexts such as mining operations, enhancing safety and operational efficiency through wireless communication and power management.

Sensor Networks: Definition, Operation & Relationship - Sensor networks include both wired and wireless configurations that use sensor nodes with sensing, processing, and communication components to monitor physical phenomena, playing a crucial role in Internet of Things (IoT) systems.

dowidth.com

dowidth.com