Industrial metaverse integrates virtual reality, digital twins, and IoT to create immersive, collaborative manufacturing environments that enhance real-time decision-making and operational efficiency. Simulation modeling uses mathematical algorithms and data to predict processes, optimize systems, and identify potential issues before physical implementation. Explore how these technologies transform manufacturing workflows and innovation.

Why it is important

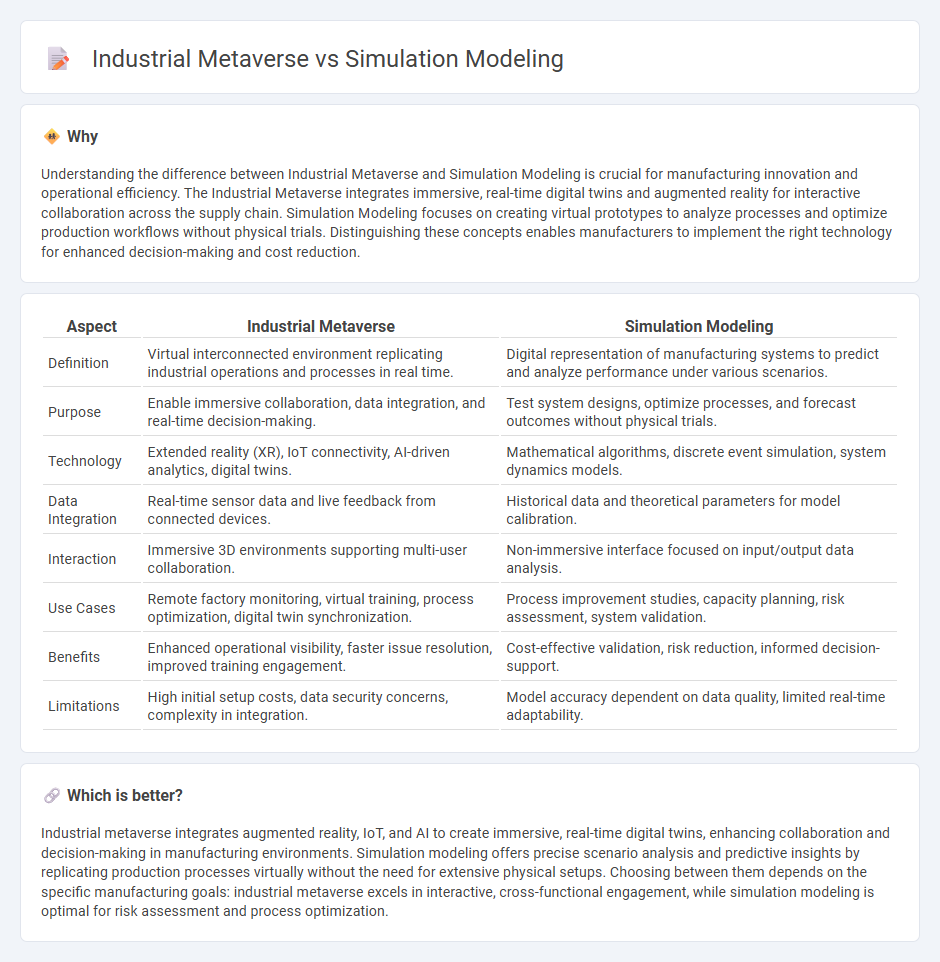

Understanding the difference between Industrial Metaverse and Simulation Modeling is crucial for manufacturing innovation and operational efficiency. The Industrial Metaverse integrates immersive, real-time digital twins and augmented reality for interactive collaboration across the supply chain. Simulation Modeling focuses on creating virtual prototypes to analyze processes and optimize production workflows without physical trials. Distinguishing these concepts enables manufacturers to implement the right technology for enhanced decision-making and cost reduction.

Comparison Table

| Aspect | Industrial Metaverse | Simulation Modeling |

|---|---|---|

| Definition | Virtual interconnected environment replicating industrial operations and processes in real time. | Digital representation of manufacturing systems to predict and analyze performance under various scenarios. |

| Purpose | Enable immersive collaboration, data integration, and real-time decision-making. | Test system designs, optimize processes, and forecast outcomes without physical trials. |

| Technology | Extended reality (XR), IoT connectivity, AI-driven analytics, digital twins. | Mathematical algorithms, discrete event simulation, system dynamics models. |

| Data Integration | Real-time sensor data and live feedback from connected devices. | Historical data and theoretical parameters for model calibration. |

| Interaction | Immersive 3D environments supporting multi-user collaboration. | Non-immersive interface focused on input/output data analysis. |

| Use Cases | Remote factory monitoring, virtual training, process optimization, digital twin synchronization. | Process improvement studies, capacity planning, risk assessment, system validation. |

| Benefits | Enhanced operational visibility, faster issue resolution, improved training engagement. | Cost-effective validation, risk reduction, informed decision-support. |

| Limitations | High initial setup costs, data security concerns, complexity in integration. | Model accuracy dependent on data quality, limited real-time adaptability. |

Which is better?

Industrial metaverse integrates augmented reality, IoT, and AI to create immersive, real-time digital twins, enhancing collaboration and decision-making in manufacturing environments. Simulation modeling offers precise scenario analysis and predictive insights by replicating production processes virtually without the need for extensive physical setups. Choosing between them depends on the specific manufacturing goals: industrial metaverse excels in interactive, cross-functional engagement, while simulation modeling is optimal for risk assessment and process optimization.

Connection

The Industrial Metaverse integrates advanced simulation modeling to create immersive digital twins of manufacturing processes, enabling real-time monitoring and optimization. These simulations replicate complex production environments, allowing manufacturers to test scenarios, predict outcomes, and improve efficiency without physical risks. By combining Industrial Metaverse platforms with simulation modeling, industries achieve enhanced decision-making, reduced downtime, and accelerated innovation cycles.

Key Terms

Digital Twin

Simulation modeling creates virtual replicas of physical systems to analyze performance and predict outcomes using mathematical algorithms and historical data. The industrial metaverse integrates digital twin technology into immersive, real-time virtual environments, enhancing collaboration, monitoring, and decision-making across complex industrial operations. Explore how digital twin innovations drive efficiency and connectivity in the industrial metaverse.

Virtual Reality (VR)

Simulation modeling leverages detailed algorithms to replicate real-world industrial processes, enabling precise scenario testing and optimization in a virtual environment. The industrial metaverse, powered by advanced Virtual Reality (VR) technology, integrates immersive 3D environments for interactive collaboration and real-time data visualization across industrial operations. Explore the transformative impact of VR in industrial settings to understand how these technologies redefine efficiency and innovation.

Real-time Data

Simulation modeling utilizes historical and static data to create predictive scenarios for manufacturing processes, while the industrial metaverse leverages real-time data streams from IoT sensors and digital twins for dynamic decision-making. Industrial metaverse platforms enable continuous monitoring and adaptive adjustments, enhancing operational efficiency and reducing downtime. Discover how integrating real-time data in the industrial metaverse transforms simulation modeling for smarter industrial innovation.

Source and External Links

Simulation modeling - Wikipedia - Simulation modeling is the creation and analysis of a digital prototype to predict real-world performance and understand failure modes, loads, and environmental impacts without physical prototypes.

INTRODUCTION TO MODELING AND SIMULATION - Modeling and simulation provide a method to design and evaluate complex systems by representing inputs, outputs, and parameters, enabling numerical estimation of system behavior when analytical solutions are not possible.

4 types of simulation models used in data analytics - TechTarget - Simulation models, including Monte Carlo, agent-based, discrete event, and system dynamics, are used in data analytics to test and predict the behavior of complex systems virtually, supporting risk-free decision-making.

dowidth.com

dowidth.com