Collaborative robots, or cobots, offer flexible automation with built-in safety features for direct human interaction, enhancing productivity in small to medium batch manufacturing. CNC machines provide precise, repeatable machining capabilities ideal for high-volume production and complex component fabrication. Explore the advantages of each technology to optimize your manufacturing processes.

Why it is important

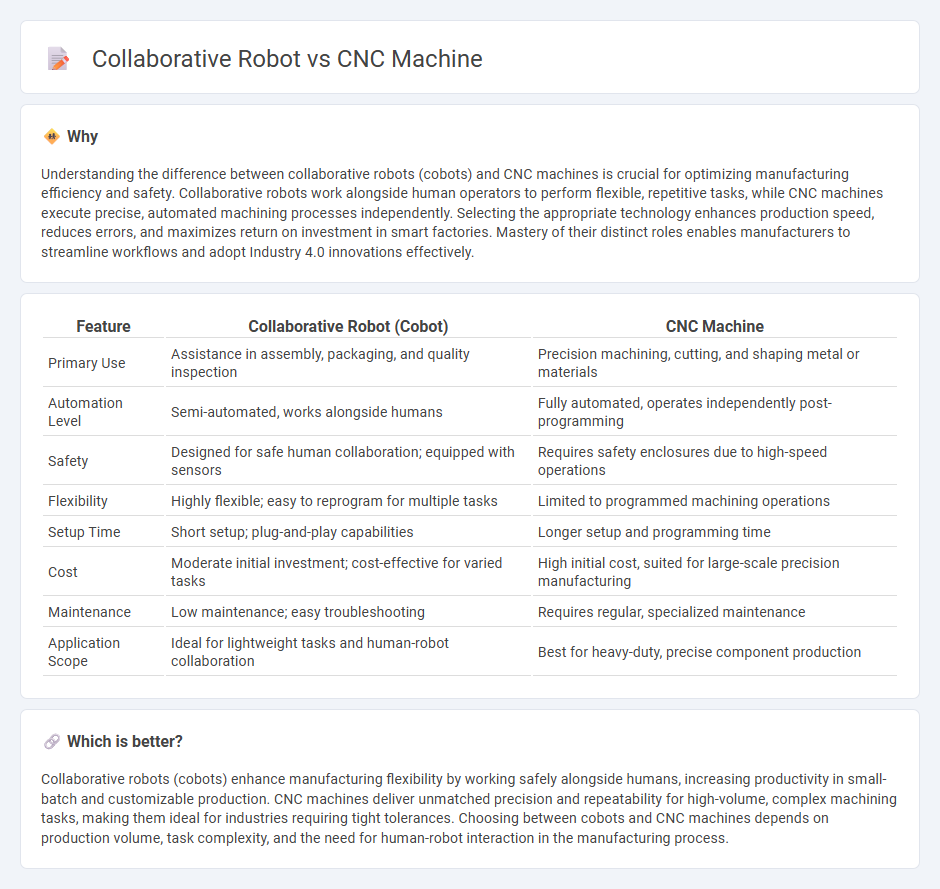

Understanding the difference between collaborative robots (cobots) and CNC machines is crucial for optimizing manufacturing efficiency and safety. Collaborative robots work alongside human operators to perform flexible, repetitive tasks, while CNC machines execute precise, automated machining processes independently. Selecting the appropriate technology enhances production speed, reduces errors, and maximizes return on investment in smart factories. Mastery of their distinct roles enables manufacturers to streamline workflows and adopt Industry 4.0 innovations effectively.

Comparison Table

| Feature | Collaborative Robot (Cobot) | CNC Machine |

|---|---|---|

| Primary Use | Assistance in assembly, packaging, and quality inspection | Precision machining, cutting, and shaping metal or materials |

| Automation Level | Semi-automated, works alongside humans | Fully automated, operates independently post-programming |

| Safety | Designed for safe human collaboration; equipped with sensors | Requires safety enclosures due to high-speed operations |

| Flexibility | Highly flexible; easy to reprogram for multiple tasks | Limited to programmed machining operations |

| Setup Time | Short setup; plug-and-play capabilities | Longer setup and programming time |

| Cost | Moderate initial investment; cost-effective for varied tasks | High initial cost, suited for large-scale precision manufacturing |

| Maintenance | Low maintenance; easy troubleshooting | Requires regular, specialized maintenance |

| Application Scope | Ideal for lightweight tasks and human-robot collaboration | Best for heavy-duty, precise component production |

Which is better?

Collaborative robots (cobots) enhance manufacturing flexibility by working safely alongside humans, increasing productivity in small-batch and customizable production. CNC machines deliver unmatched precision and repeatability for high-volume, complex machining tasks, making them ideal for industries requiring tight tolerances. Choosing between cobots and CNC machines depends on production volume, task complexity, and the need for human-robot interaction in the manufacturing process.

Connection

Collaborative robots (cobots) and CNC machines integrate seamlessly to enhance manufacturing precision and efficiency by automating complex machining processes and real-time quality control. Cobots assist CNC operations through tasks such as material loading, part inspection, and tool changes, reducing downtime and extending machine utilization. This synergy enables smart factory environments where data exchange and adaptive workflows improve throughput and reduce operational costs.

Key Terms

Automation

CNC machines offer precision and repeatability in automated manufacturing processes, excelling in high-volume production where complex parts require consistent machining. Collaborative robots, or cobots, enhance automation by working safely alongside human operators, providing flexibility and adaptability in dynamic production environments. Discover how combining CNC technology with collaborative robots can revolutionize your automation strategy.

Precision

CNC machines deliver high precision with repeatability measured in microns, ideal for complex machining tasks requiring exact tolerances. Collaborative robots offer flexibility and moderate precision, suitable for assembly and inspection where adaptability is key but ultra-fine accuracy is less critical. Explore how precision requirements influence the choice between CNC machines and collaborative robots.

Human-robot interaction

CNC machines operate with minimal human interaction, primarily requiring programming and maintenance expertise, whereas collaborative robots (cobots) are designed for direct physical interaction with human workers in shared workspaces, enhancing safety and ergonomics through sensors and adaptive behaviors. Cobots improve productivity by enabling teams to work alongside machines, dynamically adjusting to human actions without compromising efficiency or safety standards. Explore the advancements in human-robot interaction to understand how collaborative robotics are transforming industrial workflows.

Source and External Links

What is CNC Machining? | Goodwin University - CNC (Computer Numerical Control) machining is an automated manufacturing process where computers precisely control machinery like lathes, mills, drills, and routers to fabricate parts from materials such as metal or plastic using pre-programmed instructions.

CNC Machines: What Are the Different Types? | UTI - There are various types of CNC machines, including milling machines, lathes, routers, plasma cutters, electric discharge machines, and laser cutters, each designed for specific cutting, shaping, and fabrication tasks in manufacturing.

Computer numerical control - Wikipedia - CNC systems use computer-controlled motors to move tools and workpieces along multiple axes, enabling highly accurate and repeatable operations for processes such as cutting, welding, bending, and more, with modern machines being fully electronically controlled for safety and precision.

dowidth.com

dowidth.com