Digital thread integrates real-time data from design to production, enabling seamless traceability and operational efficiency in manufacturing. Predictive maintenance leverages advanced analytics and IoT sensors to anticipate equipment failures, reducing downtime and maintenance costs. Explore how combining digital thread and predictive maintenance transforms manufacturing workflows for superior productivity.

Why it is important

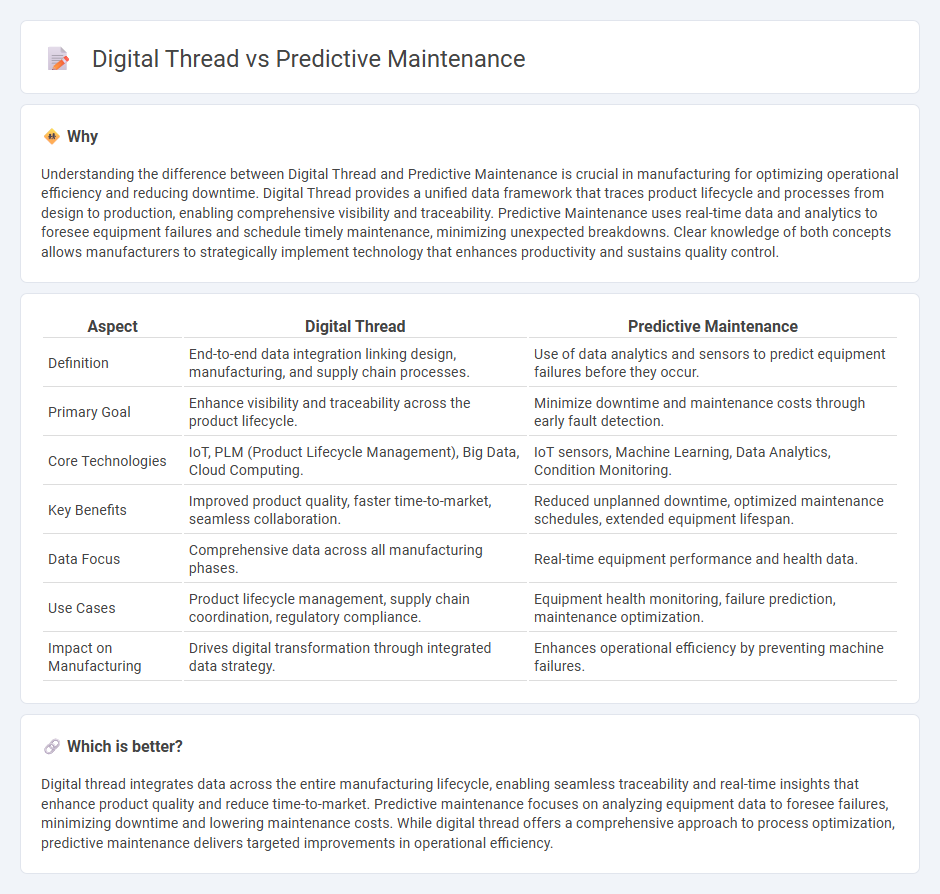

Understanding the difference between Digital Thread and Predictive Maintenance is crucial in manufacturing for optimizing operational efficiency and reducing downtime. Digital Thread provides a unified data framework that traces product lifecycle and processes from design to production, enabling comprehensive visibility and traceability. Predictive Maintenance uses real-time data and analytics to foresee equipment failures and schedule timely maintenance, minimizing unexpected breakdowns. Clear knowledge of both concepts allows manufacturers to strategically implement technology that enhances productivity and sustains quality control.

Comparison Table

| Aspect | Digital Thread | Predictive Maintenance |

|---|---|---|

| Definition | End-to-end data integration linking design, manufacturing, and supply chain processes. | Use of data analytics and sensors to predict equipment failures before they occur. |

| Primary Goal | Enhance visibility and traceability across the product lifecycle. | Minimize downtime and maintenance costs through early fault detection. |

| Core Technologies | IoT, PLM (Product Lifecycle Management), Big Data, Cloud Computing. | IoT sensors, Machine Learning, Data Analytics, Condition Monitoring. |

| Key Benefits | Improved product quality, faster time-to-market, seamless collaboration. | Reduced unplanned downtime, optimized maintenance schedules, extended equipment lifespan. |

| Data Focus | Comprehensive data across all manufacturing phases. | Real-time equipment performance and health data. |

| Use Cases | Product lifecycle management, supply chain coordination, regulatory compliance. | Equipment health monitoring, failure prediction, maintenance optimization. |

| Impact on Manufacturing | Drives digital transformation through integrated data strategy. | Enhances operational efficiency by preventing machine failures. |

Which is better?

Digital thread integrates data across the entire manufacturing lifecycle, enabling seamless traceability and real-time insights that enhance product quality and reduce time-to-market. Predictive maintenance focuses on analyzing equipment data to foresee failures, minimizing downtime and lowering maintenance costs. While digital thread offers a comprehensive approach to process optimization, predictive maintenance delivers targeted improvements in operational efficiency.

Connection

Digital thread creates an integrated data framework that connects every stage of the manufacturing lifecycle, enabling real-time visibility and traceability of equipment performance. Predictive maintenance leverages this continuous data flow to analyze machine conditions and forecast failures before they occur, reducing downtime and maintenance costs. The synergy between digital thread and predictive maintenance enhances operational efficiency and extends asset lifespan through timely, data-driven interventions.

Key Terms

**Predictive Maintenance:**

Predictive maintenance leverages real-time data and machine learning algorithms to anticipate equipment failures, reducing downtime and lowering maintenance costs. This approach uses sensors and IoT devices to continuously monitor asset conditions, enabling proactive interventions before issues escalate. Explore how predictive maintenance transforms operational efficiency and asset management in modern industries.

Condition monitoring

Predictive maintenance leverages real-time sensor data and AI algorithms to anticipate equipment failures by continuously monitoring conditions such as temperature, vibration, and pressure, thereby reducing downtime and maintenance costs. The digital thread integrates this condition monitoring data across the entire product lifecycle, enabling seamless information flow from design to operation and facilitating more informed maintenance decisions. Explore how the synergy between predictive maintenance and the digital thread enhances equipment reliability and operational efficiency.

Machine learning

Predictive maintenance leverages machine learning algorithms to analyze sensor data and predict equipment failures before they occur, minimizing downtime and maintenance costs. The digital thread integrates machine learning within a comprehensive data framework, connecting design, production, and operational data to optimize asset performance throughout its lifecycle. Explore how machine learning enhances both predictive maintenance and digital thread strategies for smarter manufacturing.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses real-time sensor data and advanced analytics to anticipate equipment failures and schedule maintenance only when truly needed, optimizing costs and reducing downtime.

Predictive maintenance - Wikipedia - Predictive maintenance estimates when maintenance is required by monitoring current equipment conditions, aiming to improve scheduling, increase safety, and prolong equipment lifespan.

What is Predictive Maintenance? Benefits, Challenges & Examples - Predictive maintenance leverages data and analytics to alert managers of potential issues before they occur, optimizing maintenance, reducing breakdowns, and increasing fleet efficiency.

dowidth.com

dowidth.com