Microfactories streamline manufacturing by integrating compact, flexible production units that enable localized and rapid response to market demands. Just-in-time manufacturing reduces inventory costs and waste by synchronizing production schedules closely with demand to deliver materials exactly when needed. Explore the advantages and applications of these manufacturing approaches to enhance operational efficiency.

Why it is important

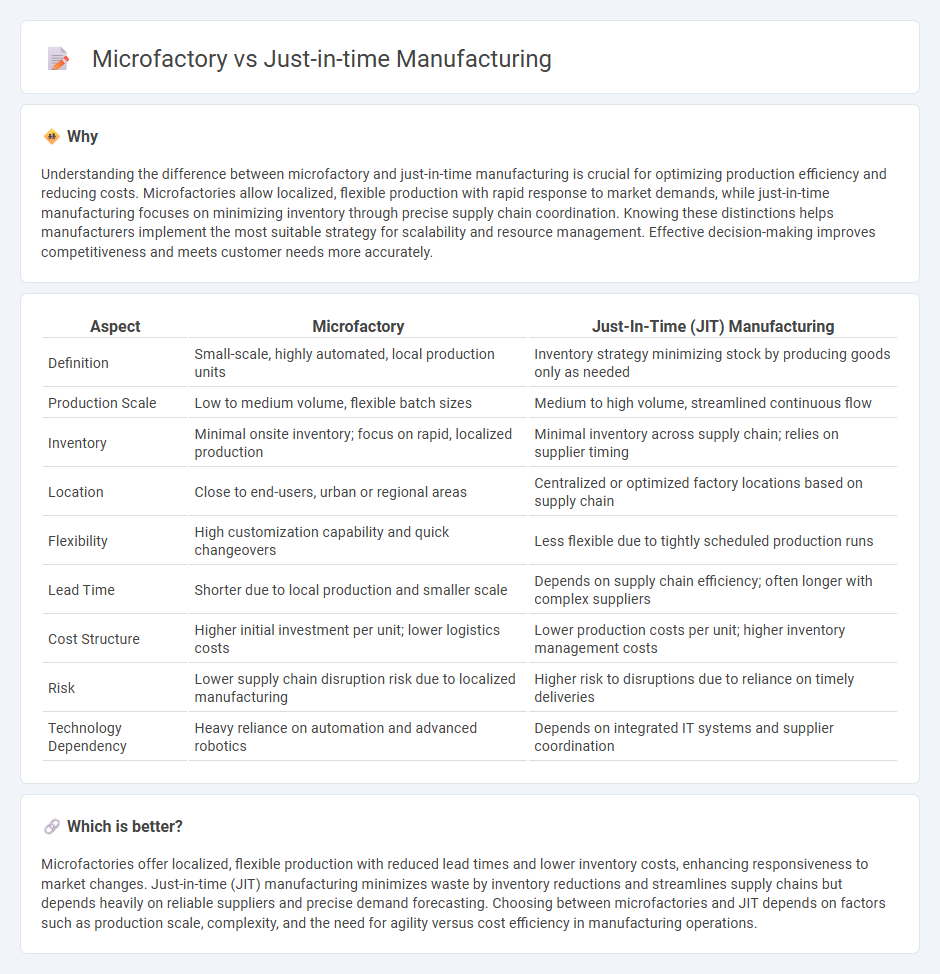

Understanding the difference between microfactory and just-in-time manufacturing is crucial for optimizing production efficiency and reducing costs. Microfactories allow localized, flexible production with rapid response to market demands, while just-in-time manufacturing focuses on minimizing inventory through precise supply chain coordination. Knowing these distinctions helps manufacturers implement the most suitable strategy for scalability and resource management. Effective decision-making improves competitiveness and meets customer needs more accurately.

Comparison Table

| Aspect | Microfactory | Just-In-Time (JIT) Manufacturing |

|---|---|---|

| Definition | Small-scale, highly automated, local production units | Inventory strategy minimizing stock by producing goods only as needed |

| Production Scale | Low to medium volume, flexible batch sizes | Medium to high volume, streamlined continuous flow |

| Inventory | Minimal onsite inventory; focus on rapid, localized production | Minimal inventory across supply chain; relies on supplier timing |

| Location | Close to end-users, urban or regional areas | Centralized or optimized factory locations based on supply chain |

| Flexibility | High customization capability and quick changeovers | Less flexible due to tightly scheduled production runs |

| Lead Time | Shorter due to local production and smaller scale | Depends on supply chain efficiency; often longer with complex suppliers |

| Cost Structure | Higher initial investment per unit; lower logistics costs | Lower production costs per unit; higher inventory management costs |

| Risk | Lower supply chain disruption risk due to localized manufacturing | Higher risk to disruptions due to reliance on timely deliveries |

| Technology Dependency | Heavy reliance on automation and advanced robotics | Depends on integrated IT systems and supplier coordination |

Which is better?

Microfactories offer localized, flexible production with reduced lead times and lower inventory costs, enhancing responsiveness to market changes. Just-in-time (JIT) manufacturing minimizes waste by inventory reductions and streamlines supply chains but depends heavily on reliable suppliers and precise demand forecasting. Choosing between microfactories and JIT depends on factors such as production scale, complexity, and the need for agility versus cost efficiency in manufacturing operations.

Connection

Microfactories leverage just-in-time manufacturing by producing goods in small, flexible batches, reducing inventory costs and minimizing waste. This approach streamlines production schedules, allowing manufacturers to respond quickly to demand fluctuations. Integration of microfactory design with just-in-time principles enhances operational efficiency and agility in supply chains.

Key Terms

Inventory Management

Just-in-time manufacturing minimizes inventory levels by synchronizing production schedules closely with demand, reducing storage costs and waste. Microfactories leverage compact, flexible production units to enable rapid inventory replenishment and localized supply chains, enhancing responsiveness and reducing lead times. Explore how these innovative approaches transform inventory management for efficiency and agility.

Production Scale

Just-in-time manufacturing optimizes large-scale production by minimizing inventory and reducing waste through precise demand forecasting, enhancing efficiency in mass production environments. Microfactories prioritize agility and rapid customization, operating on a smaller scale to deliver localized, flexible manufacturing with lower overhead costs. Explore how these production scales impact operational strategies and supply chain resilience.

Flexibility

Just-in-time manufacturing minimizes inventory by producing goods only as needed, emphasizing demand-driven flexibility but often relying on complex supply chains. Microfactories offer enhanced operational flexibility through compact, modular designs that enable rapid reconfiguration and localized production for diverse product lines. Explore how these approaches redefine manufacturing agility and responsiveness.

Source and External Links

Just In Time Manufacturing: Definition, Benefits, and Origin - Just-in-time (JIT) manufacturing is a strategy that increases efficiency and reduces waste by producing goods only as needed, enabling companies to better match supply with demand and improve production processes.

What is just-in-time manufacturing (JIT manufacturing)? - JIT manufacturing is a production model where items are created to meet actual demand rather than in surplus or in advance, aiming to cut costs, eliminate waste, and speed up delivery by focusing on overproduction and inventory reduction.

What is Just-in-Time Manufacturing (JIT)? - Planview - JIT is a workflow methodology that reduces production flow times and supplier response times by strictly limiting inventory and emphasizing continuous improvement, defect elimination, and flexible, visible processes.

dowidth.com

dowidth.com