Soft robotics utilizes flexible materials and bio-inspired designs to perform delicate, adaptive tasks in manufacturing, contrasting with traditional robotics that rely on rigid structures and precise, repetitive movements. This innovation enhances safety and versatility in handling fragile components, expanding automation possibilities across industries such as electronics and healthcare. Explore how soft robotics is transforming manufacturing efficiency and capability.

Why it is important

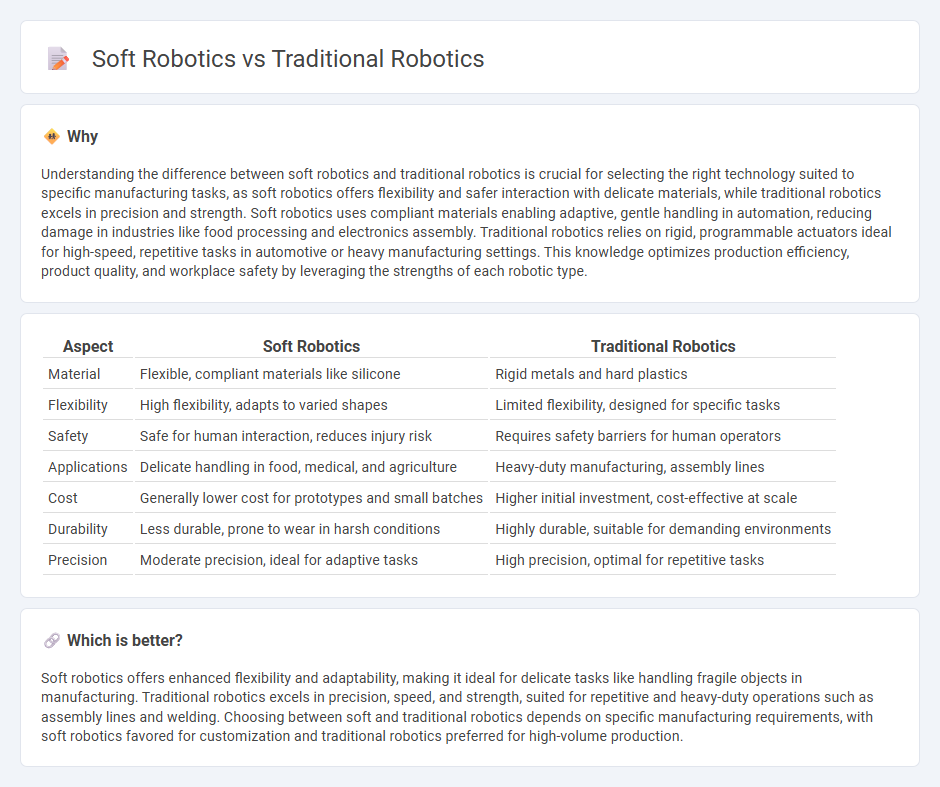

Understanding the difference between soft robotics and traditional robotics is crucial for selecting the right technology suited to specific manufacturing tasks, as soft robotics offers flexibility and safer interaction with delicate materials, while traditional robotics excels in precision and strength. Soft robotics uses compliant materials enabling adaptive, gentle handling in automation, reducing damage in industries like food processing and electronics assembly. Traditional robotics relies on rigid, programmable actuators ideal for high-speed, repetitive tasks in automotive or heavy manufacturing settings. This knowledge optimizes production efficiency, product quality, and workplace safety by leveraging the strengths of each robotic type.

Comparison Table

| Aspect | Soft Robotics | Traditional Robotics |

|---|---|---|

| Material | Flexible, compliant materials like silicone | Rigid metals and hard plastics |

| Flexibility | High flexibility, adapts to varied shapes | Limited flexibility, designed for specific tasks |

| Safety | Safe for human interaction, reduces injury risk | Requires safety barriers for human operators |

| Applications | Delicate handling in food, medical, and agriculture | Heavy-duty manufacturing, assembly lines |

| Cost | Generally lower cost for prototypes and small batches | Higher initial investment, cost-effective at scale |

| Durability | Less durable, prone to wear in harsh conditions | Highly durable, suitable for demanding environments |

| Precision | Moderate precision, ideal for adaptive tasks | High precision, optimal for repetitive tasks |

Which is better?

Soft robotics offers enhanced flexibility and adaptability, making it ideal for delicate tasks like handling fragile objects in manufacturing. Traditional robotics excels in precision, speed, and strength, suited for repetitive and heavy-duty operations such as assembly lines and welding. Choosing between soft and traditional robotics depends on specific manufacturing requirements, with soft robotics favored for customization and traditional robotics preferred for high-volume production.

Connection

Soft robotics and traditional robotics are interconnected through their complementary applications in manufacturing, where traditional robots provide precision and high-speed automation while soft robots offer adaptability and safe interaction with delicate materials. Integrating soft robotics with rigid robotic systems enhances production lines by increasing flexibility, improving human-robot collaboration, and enabling new capabilities such as handling irregularly shaped objects. This synergy drives innovation in smart factories, optimizing efficiency and reducing downtime across diverse industrial processes.

Key Terms

Rigid actuators vs. Soft actuators

Rigid actuators in traditional robotics provide precise control and high force output by using solid materials like metals and hard plastics, enabling tasks that require strength and stability. Soft actuators in soft robotics utilize flexible, elastic materials such as silicone and shape-memory alloys to mimic natural movements, offering safer interactions and adaptability for delicate or unpredictable environments. Explore the advancements in actuation technology to understand how these differences impact applications across industries.

Fixed automation vs. Adaptive automation

Traditional robotics primarily employs fixed automation engineered for repetitive, high-precision tasks in controlled environments, optimizing efficiency and consistency but lacking flexibility. Soft robotics leverages adaptive automation techniques using compliant materials and sensors, enabling robots to interact safely with dynamic and unstructured surroundings while adjusting to unexpected changes. Explore the evolving landscape of robotic automation to understand the distinct applications and innovations driving both fixed and adaptive systems.

Safety cages vs. Human-robot collaboration

Traditional robotics often rely on safety cages to prevent human-robot collisions, ensuring operational security but limiting workspace flexibility. Soft robotics employs compliant, flexible materials that enable safer human-robot collaboration without extensive physical barriers, enhancing interactive tasks and adaptability in dynamic environments. Explore the latest advancements in human-robot collaboration to understand the transformative potential of soft robotics safety innovations.

Source and External Links

Traditional and modern approaches to robotics - RoboticsBiz - Traditional robotics relies on explicit internal world models, symbolic reasoning, and centralized control, with robots like Shakey from SRI using vision and logic models to navigate structured environments.

Collaborative Robots vs. Traditional Robots: What's Right for Your... - Traditional robots are powerful, fast, and precise for repetitive industrial tasks, but are typically isolated from human workers due to safety concerns because of their large, hazardous moving parts.

Collaborative robots vs. traditional robots: a comparative guide - Niryo - Traditional robots are known for high efficiency, precision, and durability, excelling in demanding tasks like welding, painting, and palletizing, but require significant space and safety measures.

dowidth.com

dowidth.com