Flexible manufacturing systems enable rapid adaptation to product changes with minimal downtime, optimizing efficiency for customized orders and varying volumes. Batch production involves producing goods in defined quantities, balancing efficiency and flexibility but often requiring setup time between batches. Explore the distinct benefits and applications of flexible manufacturing versus batch production to determine the best fit for your business needs.

Why it is important

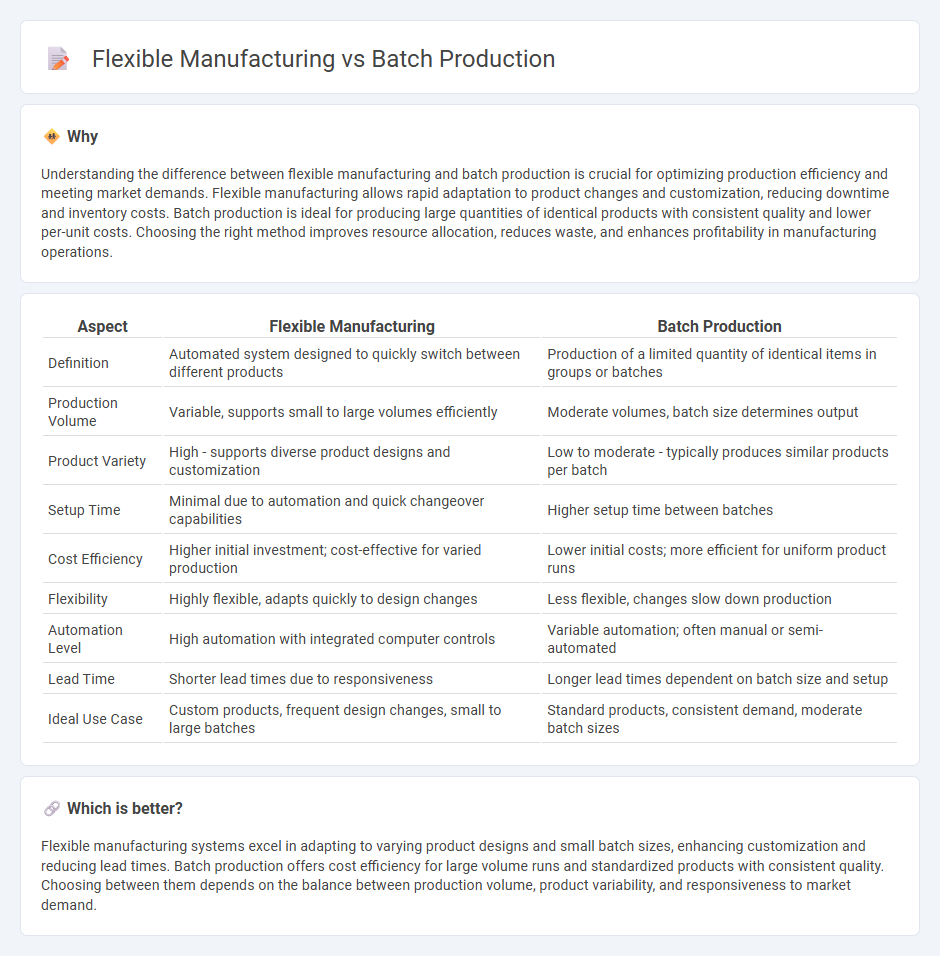

Understanding the difference between flexible manufacturing and batch production is crucial for optimizing production efficiency and meeting market demands. Flexible manufacturing allows rapid adaptation to product changes and customization, reducing downtime and inventory costs. Batch production is ideal for producing large quantities of identical products with consistent quality and lower per-unit costs. Choosing the right method improves resource allocation, reduces waste, and enhances profitability in manufacturing operations.

Comparison Table

| Aspect | Flexible Manufacturing | Batch Production |

|---|---|---|

| Definition | Automated system designed to quickly switch between different products | Production of a limited quantity of identical items in groups or batches |

| Production Volume | Variable, supports small to large volumes efficiently | Moderate volumes, batch size determines output |

| Product Variety | High - supports diverse product designs and customization | Low to moderate - typically produces similar products per batch |

| Setup Time | Minimal due to automation and quick changeover capabilities | Higher setup time between batches |

| Cost Efficiency | Higher initial investment; cost-effective for varied production | Lower initial costs; more efficient for uniform product runs |

| Flexibility | Highly flexible, adapts quickly to design changes | Less flexible, changes slow down production |

| Automation Level | High automation with integrated computer controls | Variable automation; often manual or semi-automated |

| Lead Time | Shorter lead times due to responsiveness | Longer lead times dependent on batch size and setup |

| Ideal Use Case | Custom products, frequent design changes, small to large batches | Standard products, consistent demand, moderate batch sizes |

Which is better?

Flexible manufacturing systems excel in adapting to varying product designs and small batch sizes, enhancing customization and reducing lead times. Batch production offers cost efficiency for large volume runs and standardized products with consistent quality. Choosing between them depends on the balance between production volume, product variability, and responsiveness to market demand.

Connection

Flexible manufacturing systems (FMS) enhance batch production by enabling quick adjustments in machinery and processes to accommodate varied product types within a single production run. This adaptability reduces downtime and increases efficiency, allowing manufacturers to respond swiftly to changing market demands. Integration of flexible manufacturing with batch production supports optimized resource utilization and improved production scalability.

Key Terms

Volume

Batch production efficiently handles moderate volumes by producing goods in set quantities, minimizing setup times between batches. Flexible manufacturing adapts seamlessly to varying volumes, quickly scaling production up or down without sacrificing efficiency. Explore the advantages and applications of each method to determine the best fit for your production needs.

Customization

Batch production offers limited customization by producing goods in fixed quantities with standardized processes, making it suitable for moderate variety but constrained adaptability. Flexible manufacturing systems enhance customization by enabling quick adjustments in production setups, allowing diverse product variations without significant downtime or cost increase. Explore how flexible manufacturing can transform your customization capabilities and meet dynamic market demands.

Production line configuration

Batch production configures production lines to process similar products in groups, optimizing equipment setup for specific product runs and minimizing changeover times. Flexible manufacturing systems employ modular and adaptable production line configurations that allow quick transitions between different products without extensive retooling, enhancing responsiveness to market demand. Explore the advantages of each system to determine the ideal production line setup for your manufacturing needs.

Source and External Links

What is batch production in manufacturing? - Batch production is a manufacturing method where groups of identical products are produced simultaneously, allowing flexibility to change product specifications between batches and conduct quality checks after each production stage.

Batch Production - Benefits, Examples, and Tips - Batch production involves producing sets of identical products through production steps together, offering advantages such as flexibility, quality control, and lower costs, but with disadvantages like higher work-in-progress inventory and idle time.

Batch Production: Examples, Advantages and Disadvantages - Batch production is a process where a batch of products moves through manufacturing stages together, enabling quality checks at each stage and machinery testing between batches for consistent performance.

dowidth.com

dowidth.com