Additive manufacturing builds components layer by layer using digital models, enabling complex geometries and reduced material waste. Casting involves pouring molten metal into molds, ideal for high-volume production with established material properties. Discover how these processes impact manufacturing efficiency and product design.

Why it is important

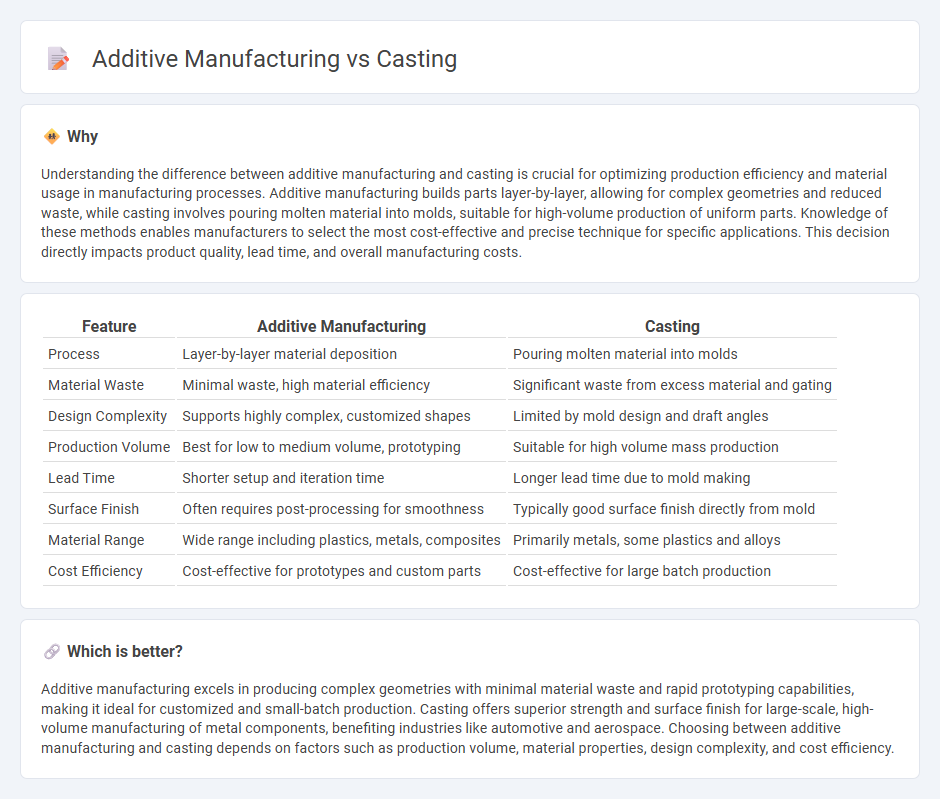

Understanding the difference between additive manufacturing and casting is crucial for optimizing production efficiency and material usage in manufacturing processes. Additive manufacturing builds parts layer-by-layer, allowing for complex geometries and reduced waste, while casting involves pouring molten material into molds, suitable for high-volume production of uniform parts. Knowledge of these methods enables manufacturers to select the most cost-effective and precise technique for specific applications. This decision directly impacts product quality, lead time, and overall manufacturing costs.

Comparison Table

| Feature | Additive Manufacturing | Casting |

|---|---|---|

| Process | Layer-by-layer material deposition | Pouring molten material into molds |

| Material Waste | Minimal waste, high material efficiency | Significant waste from excess material and gating |

| Design Complexity | Supports highly complex, customized shapes | Limited by mold design and draft angles |

| Production Volume | Best for low to medium volume, prototyping | Suitable for high volume mass production |

| Lead Time | Shorter setup and iteration time | Longer lead time due to mold making |

| Surface Finish | Often requires post-processing for smoothness | Typically good surface finish directly from mold |

| Material Range | Wide range including plastics, metals, composites | Primarily metals, some plastics and alloys |

| Cost Efficiency | Cost-effective for prototypes and custom parts | Cost-effective for large batch production |

Which is better?

Additive manufacturing excels in producing complex geometries with minimal material waste and rapid prototyping capabilities, making it ideal for customized and small-batch production. Casting offers superior strength and surface finish for large-scale, high-volume manufacturing of metal components, benefiting industries like automotive and aerospace. Choosing between additive manufacturing and casting depends on factors such as production volume, material properties, design complexity, and cost efficiency.

Connection

Additive manufacturing and casting both serve as integral processes in advanced manufacturing, enabling the production of complex and customized components with precision. Additive manufacturing creates detailed prototypes and molds layer by layer, which can then be used in casting processes to produce metal parts with high accuracy and reduced lead times. The synergy between additive manufacturing and casting enhances design flexibility, reduces material waste, and accelerates product development cycles in various industrial sectors.

Key Terms

Mold

Casting typically involves creating a mold from materials such as sand, metal, or ceramic, which shapes the molten material poured into it, allowing for mass production of complex parts with good surface finish. Additive manufacturing, on the other hand, often reduces the need for traditional molds by building parts layer-by-layer directly from digital models, enabling rapid prototyping and customization while minimizing material waste. Explore more about how mold design impacts efficiency and quality in both casting and additive manufacturing processes.

Layer-by-layer

Casting forms objects by pouring molten material into molds, relying on traditional shaping techniques, while additive manufacturing builds components layer-by-layer, enabling intricate geometries and precise control over material deposition. The layer-by-layer process in additive manufacturing allows for customization, reduced waste, and optimization of mechanical properties through controlled material placement. Explore the detailed advantages of layer-by-layer construction in additive manufacturing to better understand its impact on modern fabrication.

Material feedstock

Casting utilizes molten metal or alloy feedstock poured into molds to form parts, often requiring high-quality raw materials for optimal flow and solidification. Additive manufacturing employs granular powders, filaments, or liquid resins as feedstock, enabling precise layer-by-layer material deposition and reduced waste. Explore detailed comparisons of material feedstock selection and its impact on manufacturing efficiency and product properties.

Source and External Links

Casting - Wikipedia - Casting is a manufacturing process where liquid material is poured into a mold containing a hollow cavity in the desired shape, then solidified to create complex shapes typically in metals, epoxy, concrete, plaster, or clay.

Casting Frontier: Auditions & Casting Calls | Casting Talent - Casting Frontier is a platform connecting actors and performers with casting directors, allowing users to find, audition, and book acting roles for film, TV, commercials, and more.

Central Casting - Central Casting is a leading background actor casting company in the U.S., managing hundreds of casting roles daily and providing info and support for background actors working on film and TV sets.

dowidth.com

dowidth.com