Zero Defect Manufacturing focuses on eliminating defects entirely through rigorous quality control and process standardization, aiming for flawless production output. Six Sigma employs statistical methods and data-driven analysis to reduce process variation and defects, targeting a maximum of 3.4 defects per million opportunities. Explore how these methodologies enhance manufacturing efficiency and quality standards.

Why it is important

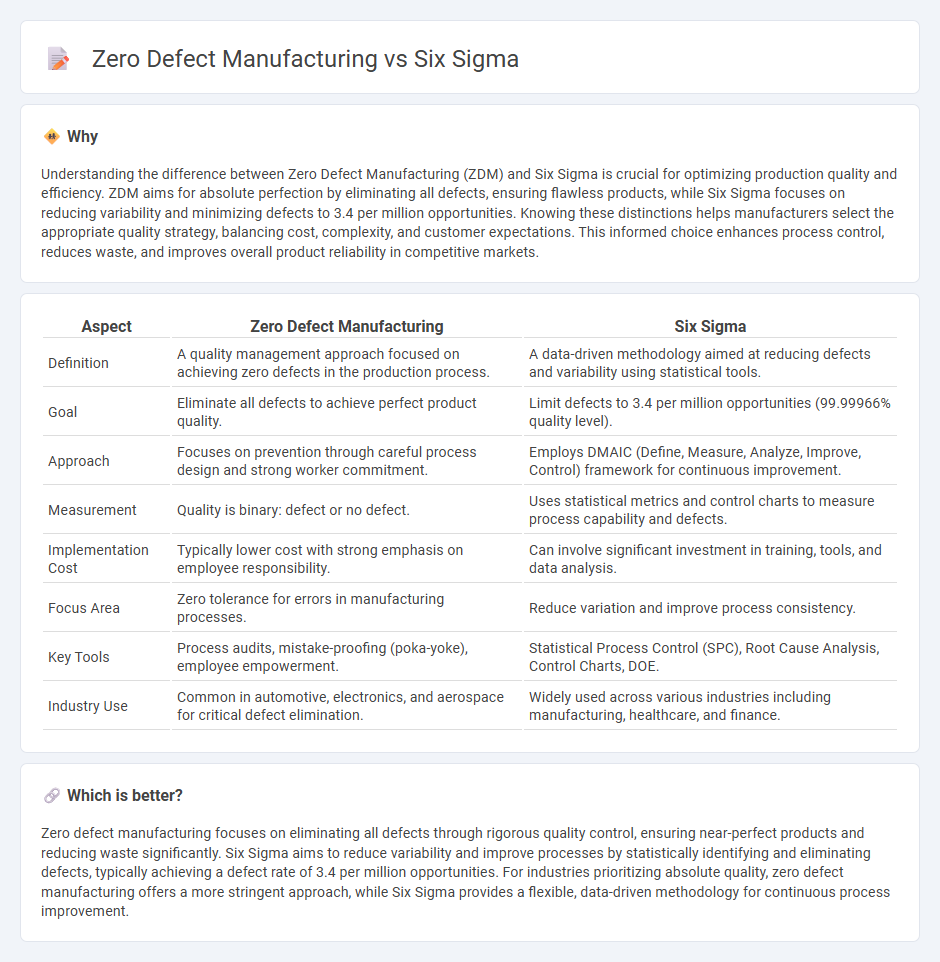

Understanding the difference between Zero Defect Manufacturing (ZDM) and Six Sigma is crucial for optimizing production quality and efficiency. ZDM aims for absolute perfection by eliminating all defects, ensuring flawless products, while Six Sigma focuses on reducing variability and minimizing defects to 3.4 per million opportunities. Knowing these distinctions helps manufacturers select the appropriate quality strategy, balancing cost, complexity, and customer expectations. This informed choice enhances process control, reduces waste, and improves overall product reliability in competitive markets.

Comparison Table

| Aspect | Zero Defect Manufacturing | Six Sigma |

|---|---|---|

| Definition | A quality management approach focused on achieving zero defects in the production process. | A data-driven methodology aimed at reducing defects and variability using statistical tools. |

| Goal | Eliminate all defects to achieve perfect product quality. | Limit defects to 3.4 per million opportunities (99.99966% quality level). |

| Approach | Focuses on prevention through careful process design and strong worker commitment. | Employs DMAIC (Define, Measure, Analyze, Improve, Control) framework for continuous improvement. |

| Measurement | Quality is binary: defect or no defect. | Uses statistical metrics and control charts to measure process capability and defects. |

| Implementation Cost | Typically lower cost with strong emphasis on employee responsibility. | Can involve significant investment in training, tools, and data analysis. |

| Focus Area | Zero tolerance for errors in manufacturing processes. | Reduce variation and improve process consistency. |

| Key Tools | Process audits, mistake-proofing (poka-yoke), employee empowerment. | Statistical Process Control (SPC), Root Cause Analysis, Control Charts, DOE. |

| Industry Use | Common in automotive, electronics, and aerospace for critical defect elimination. | Widely used across various industries including manufacturing, healthcare, and finance. |

Which is better?

Zero defect manufacturing focuses on eliminating all defects through rigorous quality control, ensuring near-perfect products and reducing waste significantly. Six Sigma aims to reduce variability and improve processes by statistically identifying and eliminating defects, typically achieving a defect rate of 3.4 per million opportunities. For industries prioritizing absolute quality, zero defect manufacturing offers a more stringent approach, while Six Sigma provides a flexible, data-driven methodology for continuous process improvement.

Connection

Zero Defect Manufacturing (ZDM) and Six Sigma are connected through their shared goal of minimizing defects and improving process quality in manufacturing. Six Sigma employs data-driven methodologies and statistical tools to identify and eliminate process variations, directly supporting ZDM's objective of producing error-free products. Implementing Six Sigma techniques enables manufacturers to achieve near-zero defect rates, enhancing efficiency and customer satisfaction.

Key Terms

Defects per Million Opportunities (DPMO)

Six Sigma targets a defect rate of 3.4 defects per million opportunities (DPMO), emphasizing statistical control and process improvement to reduce variation. Zero Defect Manufacturing aims for absolute perfection with zero tolerable defects, focusing on prevention rather than inspection. Explore detailed methodologies and metrics to understand their impact on quality management.

Continuous Improvement

Six Sigma emphasizes reducing process variation through statistical analysis to achieve near-perfect quality, while Zero Defect Manufacturing focuses on preventing defects by establishing stringent error-proofing and quality standards. Both methodologies drive continuous improvement by targeting defect elimination and process optimization to enhance product reliability and customer satisfaction. Discover how integrating these approaches can elevate your manufacturing excellence.

Process Capability

Six Sigma and Zero Defect Manufacturing both aim to improve process capability but differ in approach; Six Sigma emphasizes reducing variation to achieve a process capability index (Cpk) of at least 1.5, while Zero Defect Manufacturing targets eliminating defects entirely, striving for a defect rate of near zero. Six Sigma uses statistical tools and DMAIC methodology to analyze and enhance process stability, whereas Zero Defect Manufacturing focuses on error prevention and quality at the source. Explore detailed comparisons and practical applications to understand which methodology best fits your manufacturing goals.

Source and External Links

What is Lean Six Sigma? - Six Sigma is a disciplined quality improvement method that provides organizations with tools to reduce process variation and defects, aiming for high customer satisfaction and operational excellence.

Six Sigma - Six Sigma is a set of techniques and tools for process improvement, emphasizing measurable financial returns, management leadership, and data-driven decision-making to reduce defects and process variation.

What Is Six Sigma? - Six Sigma is a structured, data-driven methodology for eliminating defects, requiring senior leadership commitment, organizational involvement, and clearly defined roles for successful implementation.

dowidth.com

dowidth.com