Digital twinning leverages real-time data and advanced simulations to create virtual replicas of manufacturing processes, enabling predictive maintenance and enhanced operational efficiency. Traditional monitoring relies on manual inspections and historical data analysis, often resulting in delayed responses to equipment issues and reduced process optimization. Discover how digital twinning transforms manufacturing by providing proactive insights and reducing downtime.

Why it is important

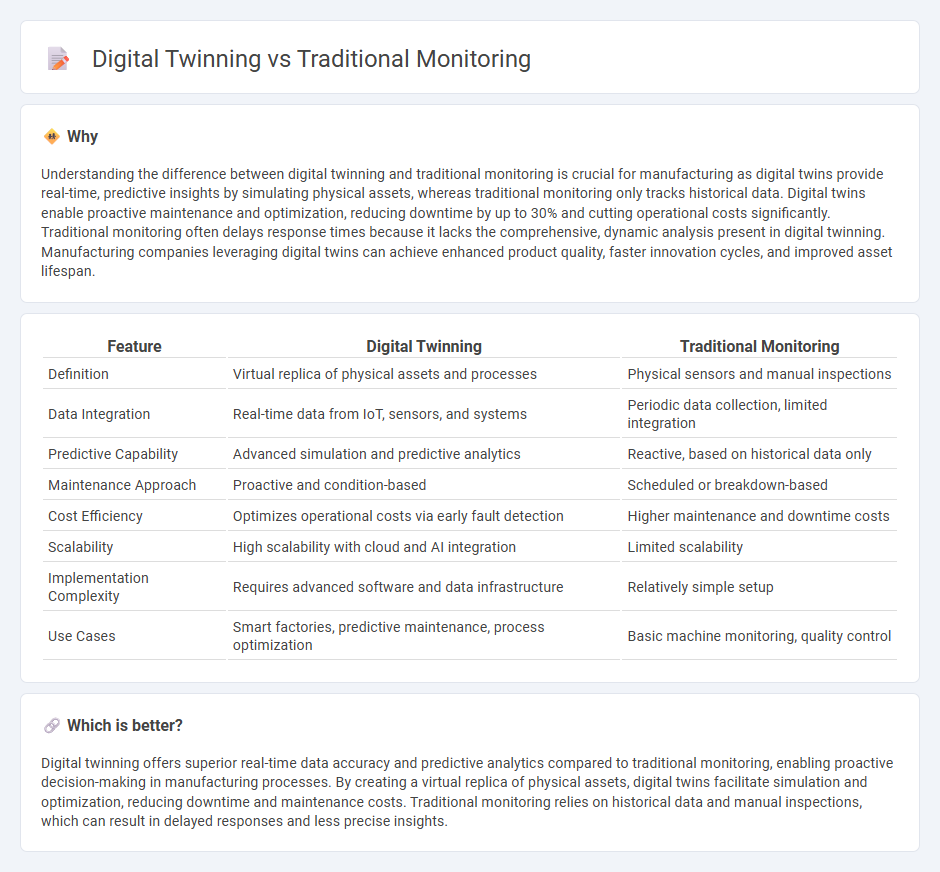

Understanding the difference between digital twinning and traditional monitoring is crucial for manufacturing as digital twins provide real-time, predictive insights by simulating physical assets, whereas traditional monitoring only tracks historical data. Digital twins enable proactive maintenance and optimization, reducing downtime by up to 30% and cutting operational costs significantly. Traditional monitoring often delays response times because it lacks the comprehensive, dynamic analysis present in digital twinning. Manufacturing companies leveraging digital twins can achieve enhanced product quality, faster innovation cycles, and improved asset lifespan.

Comparison Table

| Feature | Digital Twinning | Traditional Monitoring |

|---|---|---|

| Definition | Virtual replica of physical assets and processes | Physical sensors and manual inspections |

| Data Integration | Real-time data from IoT, sensors, and systems | Periodic data collection, limited integration |

| Predictive Capability | Advanced simulation and predictive analytics | Reactive, based on historical data only |

| Maintenance Approach | Proactive and condition-based | Scheduled or breakdown-based |

| Cost Efficiency | Optimizes operational costs via early fault detection | Higher maintenance and downtime costs |

| Scalability | High scalability with cloud and AI integration | Limited scalability |

| Implementation Complexity | Requires advanced software and data infrastructure | Relatively simple setup |

| Use Cases | Smart factories, predictive maintenance, process optimization | Basic machine monitoring, quality control |

Which is better?

Digital twinning offers superior real-time data accuracy and predictive analytics compared to traditional monitoring, enabling proactive decision-making in manufacturing processes. By creating a virtual replica of physical assets, digital twins facilitate simulation and optimization, reducing downtime and maintenance costs. Traditional monitoring relies on historical data and manual inspections, which can result in delayed responses and less precise insights.

Connection

Digital twinning enhances traditional manufacturing monitoring by creating virtual replicas of physical assets, enabling real-time data analysis and predictive maintenance. Integrating IoT sensors with traditional monitoring systems improves accuracy by continuously capturing operational parameters such as temperature, vibration, and pressure. This synergy optimizes production efficiency, reduces downtime, and supports data-driven decision-making in smart manufacturing environments.

Key Terms

Real-time data acquisition

Traditional monitoring relies on periodic data collection through manual or sensor-based methods, often resulting in delayed insights and limited situational awareness. Digital twinning enables real-time data acquisition by continuously synchronizing with physical assets via IoT sensors and cloud computing, allowing instant detection of anomalies and dynamic system simulation. Explore how digital twinning transforms data acquisition to enhance operational efficiency and predictive maintenance.

Predictive analytics

Traditional monitoring relies on real-time data collection and reactive maintenance, while digital twinning enhances predictive analytics through dynamic simulation and continuous data integration from IoT devices. By creating virtual replicas of physical assets, digital twins enable more accurate failure predictions, optimize operational efficiency, and reduce downtime significantly. Explore how digital twins revolutionize predictive analytics to drive smarter decision-making and asset management.

Physical sensor integration

Traditional monitoring systems rely heavily on physical sensor integration to collect real-time data, often limited by the placement and capabilities of these sensors. Digital twinning transcends these limitations by combining sensor data with simulation models, enabling comprehensive system analysis and predictive maintenance. Discover how integrating advanced sensor technologies within digital twins revolutionizes asset monitoring and operational efficiency.

Source and External Links

From Traditional Monitoring to AI-Enhanced Observability - Uptrace - Traditional monitoring relies on predefined static thresholds and rules to trigger alerts, is metric-focused, reactive, requires manual data correlation, and struggles with scalability in modern complex environments.

Application Performance Monitoring Software vs. Traditional Tools - Traditional monitoring tools are infrastructure-focused, reactive, and use simpler metrics-based alerts, making them suitable for legacy systems or holistic infrastructure views but less effective for application-specific insights and proactive issue detection.

SIEM Security Tool vs. Traditional Monitoring: What's the Difference? - Traditional monitoring tools track system health and performance metrics like uptime or CPU usage but lack security threat detection, correlation, or response capabilities found in modern SIEM tools.

dowidth.com

dowidth.com