Factory as a Service (FaaS) offers on-demand manufacturing resources through cloud-based platforms, optimizing production scalability and cost-efficiency. Flexible Manufacturing Systems (FMS) integrate automated machinery and computer-controlled processes to adapt quickly to product variations and volume changes. Explore how these innovative approaches transform industrial operations and drive competitive advantage.

Why it is important

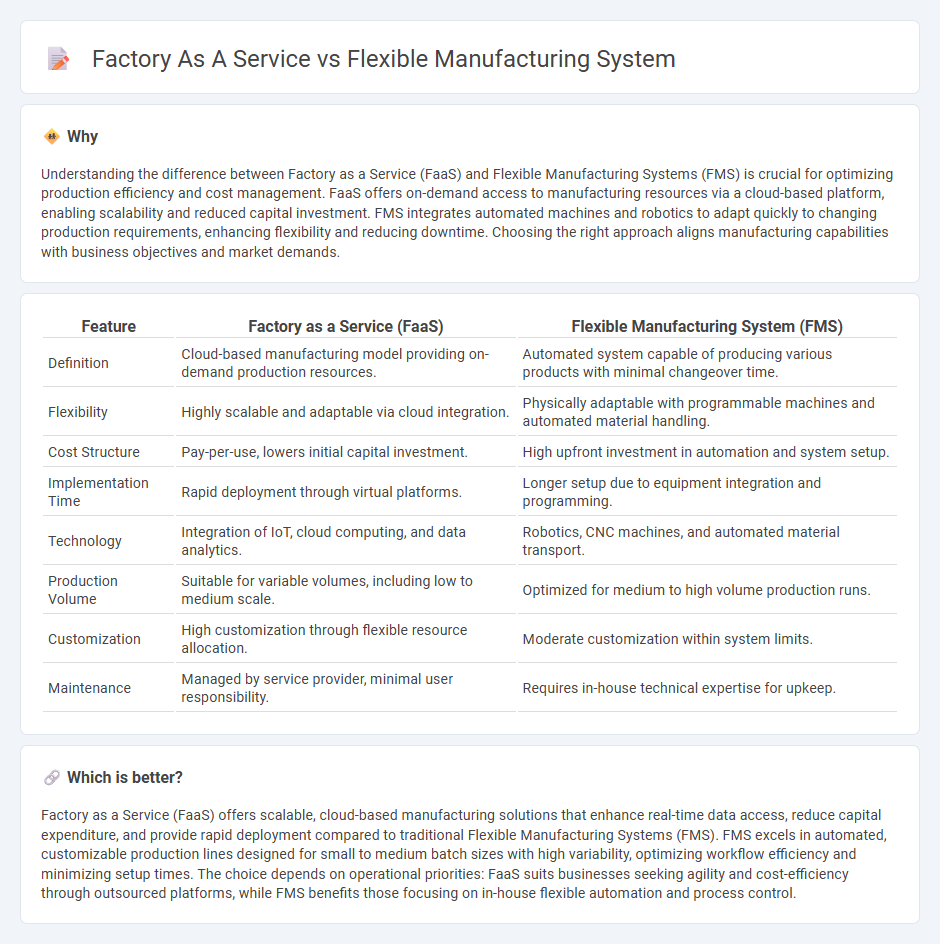

Understanding the difference between Factory as a Service (FaaS) and Flexible Manufacturing Systems (FMS) is crucial for optimizing production efficiency and cost management. FaaS offers on-demand access to manufacturing resources via a cloud-based platform, enabling scalability and reduced capital investment. FMS integrates automated machines and robotics to adapt quickly to changing production requirements, enhancing flexibility and reducing downtime. Choosing the right approach aligns manufacturing capabilities with business objectives and market demands.

Comparison Table

| Feature | Factory as a Service (FaaS) | Flexible Manufacturing System (FMS) |

|---|---|---|

| Definition | Cloud-based manufacturing model providing on-demand production resources. | Automated system capable of producing various products with minimal changeover time. |

| Flexibility | Highly scalable and adaptable via cloud integration. | Physically adaptable with programmable machines and automated material handling. |

| Cost Structure | Pay-per-use, lowers initial capital investment. | High upfront investment in automation and system setup. |

| Implementation Time | Rapid deployment through virtual platforms. | Longer setup due to equipment integration and programming. |

| Technology | Integration of IoT, cloud computing, and data analytics. | Robotics, CNC machines, and automated material transport. |

| Production Volume | Suitable for variable volumes, including low to medium scale. | Optimized for medium to high volume production runs. |

| Customization | High customization through flexible resource allocation. | Moderate customization within system limits. |

| Maintenance | Managed by service provider, minimal user responsibility. | Requires in-house technical expertise for upkeep. |

Which is better?

Factory as a Service (FaaS) offers scalable, cloud-based manufacturing solutions that enhance real-time data access, reduce capital expenditure, and provide rapid deployment compared to traditional Flexible Manufacturing Systems (FMS). FMS excels in automated, customizable production lines designed for small to medium batch sizes with high variability, optimizing workflow efficiency and minimizing setup times. The choice depends on operational priorities: FaaS suits businesses seeking agility and cost-efficiency through outsourced platforms, while FMS benefits those focusing on in-house flexible automation and process control.

Connection

Factory as a Service (FaaS) integrates cloud-based platforms with flexible manufacturing systems (FMS) to enable real-time resource sharing and adaptive production processes. FaaS leverages IoT and AI technologies within FMS to optimize machine utilization, reduce downtime, and customize manufacturing workflows on demand. This synergy enhances scalability and responsiveness, driving efficient, cost-effective production in smart factories.

Key Terms

**Flexible Manufacturing System:**

Flexible Manufacturing Systems (FMS) integrate automated machines, robotics, and computer-controlled processes to enable customizable, efficient production with minimal downtime. Unlike traditional Factory as a Service (FaaS) models that rent out fixed production capacity, FMS offers adaptability to rapid design changes and varying batch sizes, optimizing resource utilization. Explore how adopting FMS can revolutionize your manufacturing agility and operational costs.

Automation

Flexible manufacturing systems (FMS) integrate advanced robotics and computer-controlled machines to enable rapid adaptation and automation of production lines, significantly enhancing operational efficiency. Factory as a Service (FaaS) offers on-demand access to automated manufacturing resources via cloud platforms, facilitating scalability and remote management without extensive capital investment. Explore how automation transforms manufacturing by comparing FMS and FaaS to optimize your production strategy.

CNC Machines

Flexible Manufacturing Systems (FMS) utilize CNC machines to enable automated, adaptable production processes tailored to varying product designs and volumes, significantly reducing setup times and increasing efficiency. Factory as a Service (FaaS) offers on-demand CNC machining capabilities through cloud-connected facilities, providing scalability and access to advanced manufacturing without large capital investments. Explore how both models transform CNC machining workflows and operational strategies to optimize manufacturing performance.

Source and External Links

Flexible manufacturing system (Wikipedia) - A flexible manufacturing system (FMS) is a computer-controlled system that adapts to changes in product type, production volume, or operation sequence, typically consisting of automated machines, a material handling system, and a central control computer to optimize manufacturing flexibility and efficiency.

Flexible Manufacturing Systems (FMS) | What is... (Autodesk) - FMS enables businesses to quickly reconfigure production sequences or switch machines, allowing adaptation to supply disruptions, maintenance needs, or fluctuating demand without compromising product quality.

Flexible Manufacturing System Advantages And... (ARRK) - FMS offers exceptional flexibility, scalability, and customization, making it ideal for industries with variable demand and a need for rapid product changes or personalization.

dowidth.com

dowidth.com