Zero defect manufacturing aims to eliminate all defects by emphasizing flawless processes and high-quality standards, reducing waste and increasing customer satisfaction. Statistical Process Control uses data-driven techniques and control charts to monitor production variations, identifying trends before defects occur to maintain consistent quality. Explore how integrating these approaches can elevate manufacturing precision and efficiency.

Why it is important

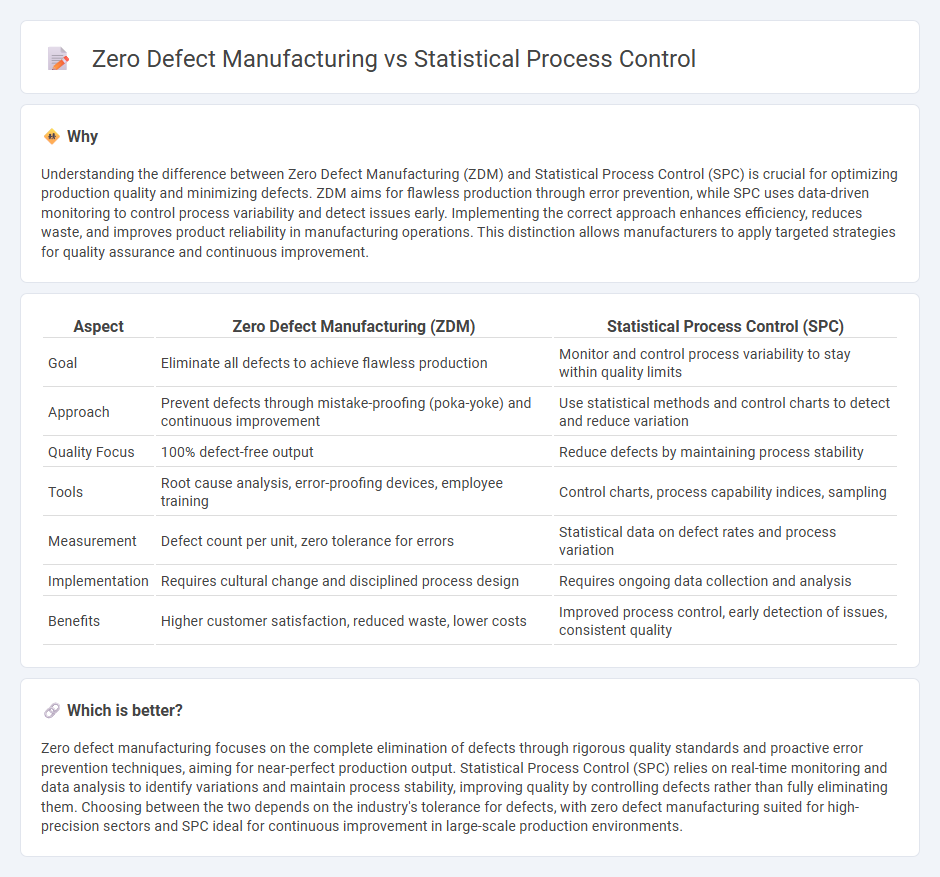

Understanding the difference between Zero Defect Manufacturing (ZDM) and Statistical Process Control (SPC) is crucial for optimizing production quality and minimizing defects. ZDM aims for flawless production through error prevention, while SPC uses data-driven monitoring to control process variability and detect issues early. Implementing the correct approach enhances efficiency, reduces waste, and improves product reliability in manufacturing operations. This distinction allows manufacturers to apply targeted strategies for quality assurance and continuous improvement.

Comparison Table

| Aspect | Zero Defect Manufacturing (ZDM) | Statistical Process Control (SPC) |

|---|---|---|

| Goal | Eliminate all defects to achieve flawless production | Monitor and control process variability to stay within quality limits |

| Approach | Prevent defects through mistake-proofing (poka-yoke) and continuous improvement | Use statistical methods and control charts to detect and reduce variation |

| Quality Focus | 100% defect-free output | Reduce defects by maintaining process stability |

| Tools | Root cause analysis, error-proofing devices, employee training | Control charts, process capability indices, sampling |

| Measurement | Defect count per unit, zero tolerance for errors | Statistical data on defect rates and process variation |

| Implementation | Requires cultural change and disciplined process design | Requires ongoing data collection and analysis |

| Benefits | Higher customer satisfaction, reduced waste, lower costs | Improved process control, early detection of issues, consistent quality |

Which is better?

Zero defect manufacturing focuses on the complete elimination of defects through rigorous quality standards and proactive error prevention techniques, aiming for near-perfect production output. Statistical Process Control (SPC) relies on real-time monitoring and data analysis to identify variations and maintain process stability, improving quality by controlling defects rather than fully eliminating them. Choosing between the two depends on the industry's tolerance for defects, with zero defect manufacturing suited for high-precision sectors and SPC ideal for continuous improvement in large-scale production environments.

Connection

Zero defect manufacturing relies heavily on Statistical Process Control (SPC) to monitor and control production processes, ensuring minimal variation and preventing defects in real-time. SPC uses data-driven techniques such as control charts to detect anomalies and maintain process stability, which is critical for achieving zero defects. Implementing SPC allows manufacturers to identify potential errors early, reduce waste, and continuously improve product quality aligned with zero defect manufacturing goals.

Key Terms

**Statistical Process Control:**

Statistical Process Control (SPC) leverages real-time data monitoring tools, such as control charts, to detect and reduce process variation, ensuring consistent product quality in manufacturing environments. Unlike Zero Defect Manufacturing, which aims for flawless output by eliminating errors, SPC emphasizes ongoing process stability and continuous improvement through statistical analysis. Explore more about how SPC enhances quality control and operational efficiency in complex production systems.

Control charts

Control charts are pivotal in Statistical Process Control (SPC) as they monitor process variability and detect deviations from stability, enabling timely interventions to maintain quality. Zero Defect Manufacturing (ZDM) aims for flawless production by minimizing defects through proactive techniques, often integrating SPC tools like control charts to prevent errors before they occur. Explore how combining control charts within SPC frameworks supports zero-defect goals for superior manufacturing quality.

Process variation

Statistical Process Control (SPC) emphasizes monitoring and controlling process variation through data-driven techniques to maintain quality within defined limits. Zero Defect Manufacturing strives to eliminate defects entirely by reducing process variation to near zero, promoting proactive error prevention rather than reactive detection. Explore the distinct methodologies and benefits of SPC and Zero Defect Manufacturing to enhance your quality management strategy.

Source and External Links

What is Statistical Process Control? SPC Quality Tools - ASQ - Statistical process control (SPC) uses statistical techniques such as control charts to monitor and control production processes, distinguishing between common cause and special cause variation to maintain process quality and improve production outcomes.

Statistical process control - Wikipedia - SPC applies statistical methods to ensure efficient production processes that produce conforming products with less waste by early detection and prevention of quality issues, typically using control charts and continuous improvement techniques.

The Ultimate Guide to Statistical Process Control (SPC) - Six Sigma - SPC is a data-driven approach focusing on understanding variation, maintaining stable processes, enabling continuous improvement, and making preventive, statistically grounded decisions to manage quality effectively.

dowidth.com

dowidth.com