Lights-out manufacturing employs fully automated, unmanned production systems that operate continuously without human intervention, maximizing efficiency and reducing labor costs. Process manufacturing involves the transformation of raw materials through chemical, physical, or biological processes into finished products, commonly used in industries like pharmaceuticals, food, and chemicals. Explore the distinct advantages and applications of these manufacturing approaches to optimize your production strategy.

Why it is important

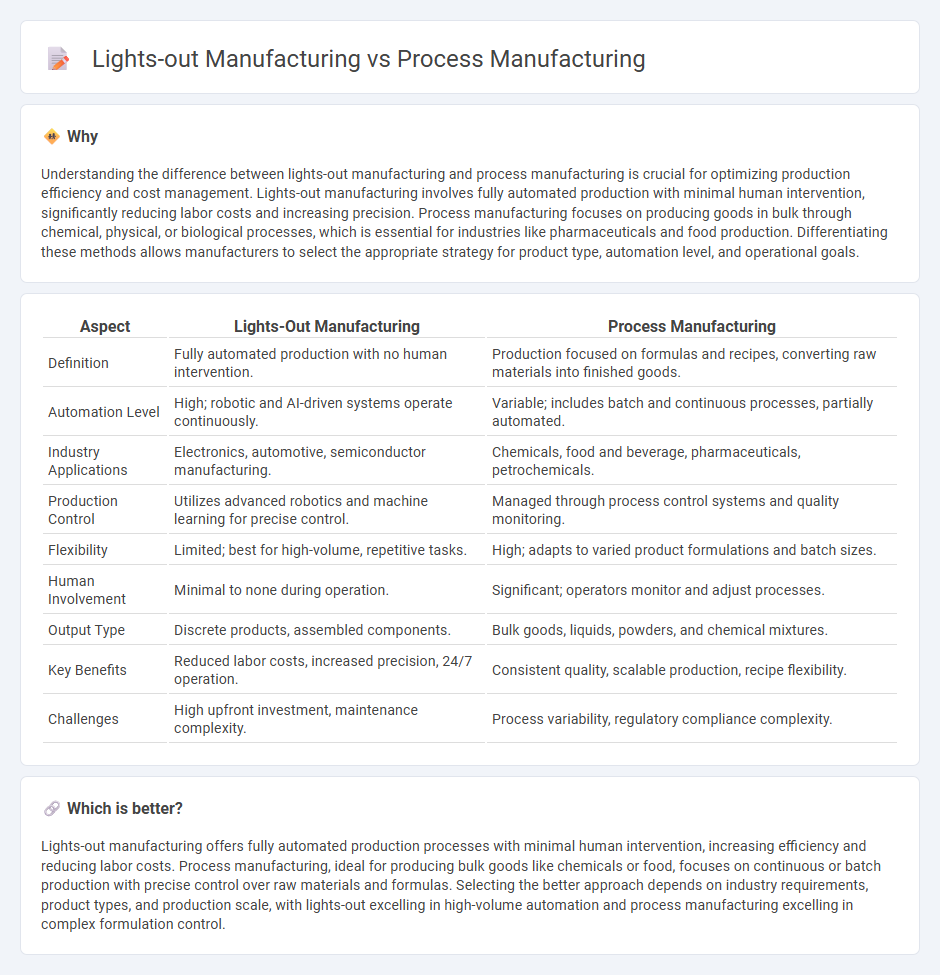

Understanding the difference between lights-out manufacturing and process manufacturing is crucial for optimizing production efficiency and cost management. Lights-out manufacturing involves fully automated production with minimal human intervention, significantly reducing labor costs and increasing precision. Process manufacturing focuses on producing goods in bulk through chemical, physical, or biological processes, which is essential for industries like pharmaceuticals and food production. Differentiating these methods allows manufacturers to select the appropriate strategy for product type, automation level, and operational goals.

Comparison Table

| Aspect | Lights-Out Manufacturing | Process Manufacturing |

|---|---|---|

| Definition | Fully automated production with no human intervention. | Production focused on formulas and recipes, converting raw materials into finished goods. |

| Automation Level | High; robotic and AI-driven systems operate continuously. | Variable; includes batch and continuous processes, partially automated. |

| Industry Applications | Electronics, automotive, semiconductor manufacturing. | Chemicals, food and beverage, pharmaceuticals, petrochemicals. |

| Production Control | Utilizes advanced robotics and machine learning for precise control. | Managed through process control systems and quality monitoring. |

| Flexibility | Limited; best for high-volume, repetitive tasks. | High; adapts to varied product formulations and batch sizes. |

| Human Involvement | Minimal to none during operation. | Significant; operators monitor and adjust processes. |

| Output Type | Discrete products, assembled components. | Bulk goods, liquids, powders, and chemical mixtures. |

| Key Benefits | Reduced labor costs, increased precision, 24/7 operation. | Consistent quality, scalable production, recipe flexibility. |

| Challenges | High upfront investment, maintenance complexity. | Process variability, regulatory compliance complexity. |

Which is better?

Lights-out manufacturing offers fully automated production processes with minimal human intervention, increasing efficiency and reducing labor costs. Process manufacturing, ideal for producing bulk goods like chemicals or food, focuses on continuous or batch production with precise control over raw materials and formulas. Selecting the better approach depends on industry requirements, product types, and production scale, with lights-out excelling in high-volume automation and process manufacturing excelling in complex formulation control.

Connection

Lights-out manufacturing leverages automation and robotics to enable unmanned production facilities, enhancing efficiency in process manufacturing industries such as chemicals, pharmaceuticals, and food production. Process manufacturing involves continuous production of goods through chemical, physical, or biological transformations, which benefits from lights-out systems by reducing human error and operational costs. Integrating lights-out technology optimizes real-time process control, improves product consistency, and accelerates throughput in complex manufacturing environments.

Key Terms

Batch Production

Batch production in process manufacturing involves the production of goods in specific quantities or batches, allowing precise control over chemical or biological processes. Lights-out manufacturing, characterized by fully automated, unattended operations, enhances efficiency and consistency in batch production by minimizing human intervention and errors. Explore more to understand how integrating automation transforms batch process manufacturing for improved quality and scalability.

Automation

Process manufacturing relies heavily on continuous production systems with automated control for chemical, pharmaceutical, or food industries, optimizing efficiency and consistency through programmable logic controllers (PLCs) and distributed control systems (DCS). Lights-out manufacturing employs fully autonomous, unmanned factory operations, using robotics, AI, and IoT sensors to enhance precision and reduce human intervention in discrete manufacturing environments. Explore the latest advancements in industrial automation to better understand how these technologies transform manufacturing processes.

Industrial Robotics

Industrial robotics in process manufacturing enhance precision and efficiency by automating repetitive tasks such as mixing, filling, and packaging within chemical, pharmaceutical, and food industries. Lights-out manufacturing leverages industrial robots for fully autonomous, 24/7 production with minimal human intervention, optimizing resource use and reducing labor costs. Explore how integrating industrial robotics transforms manufacturing workflows for better productivity and innovation.

Source and External Links

Process Manufacturing | Propel Glossary - Process manufacturing is a production method that transforms raw materials into final products through precise chemical or mechanical processes, using formulas or recipes, and is common in industries such as pharmaceuticals, chemicals, and food where consistency and quality are critical.

Process Manufacturing: Definition, Benefits, and Industries - Process manufacturing produces goods by combining ingredients under specific thermal and pressure conditions according to set formulas, resulting in homogeneous products that cannot be separated back into their original components, and is widely used in food, beverage, and chemical industries.

What is Process Manufacturing? Definition and Examples - TechTarget - In process manufacturing, goods are created in bulk through sequential, often irreversible steps following a predetermined recipe, and typical examples include food, pharmaceuticals, plastics, and fuels, with the process differing from discrete manufacturing where products are assembled from individual parts.

dowidth.com

dowidth.com