Dark factories operate with minimal or no human presence, relying heavily on automation and robotics to maintain continuous production and reduce labor costs. Cyber-physical systems integrate physical machinery with digital computing and communication, enabling real-time monitoring and adaptive control for enhanced efficiency and flexibility. Discover how these advanced manufacturing models are transforming industrial processes and driving innovation.

Why it is important

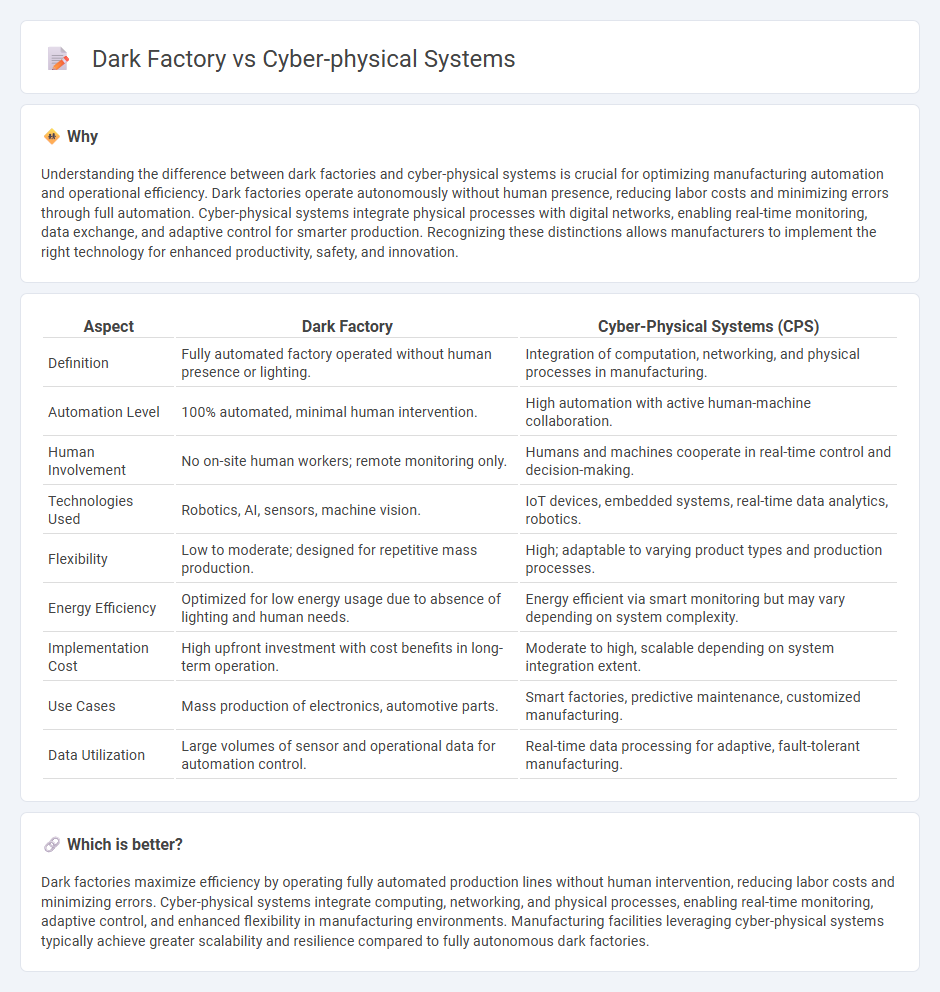

Understanding the difference between dark factories and cyber-physical systems is crucial for optimizing manufacturing automation and operational efficiency. Dark factories operate autonomously without human presence, reducing labor costs and minimizing errors through full automation. Cyber-physical systems integrate physical processes with digital networks, enabling real-time monitoring, data exchange, and adaptive control for smarter production. Recognizing these distinctions allows manufacturers to implement the right technology for enhanced productivity, safety, and innovation.

Comparison Table

| Aspect | Dark Factory | Cyber-Physical Systems (CPS) |

|---|---|---|

| Definition | Fully automated factory operated without human presence or lighting. | Integration of computation, networking, and physical processes in manufacturing. |

| Automation Level | 100% automated, minimal human intervention. | High automation with active human-machine collaboration. |

| Human Involvement | No on-site human workers; remote monitoring only. | Humans and machines cooperate in real-time control and decision-making. |

| Technologies Used | Robotics, AI, sensors, machine vision. | IoT devices, embedded systems, real-time data analytics, robotics. |

| Flexibility | Low to moderate; designed for repetitive mass production. | High; adaptable to varying product types and production processes. |

| Energy Efficiency | Optimized for low energy usage due to absence of lighting and human needs. | Energy efficient via smart monitoring but may vary depending on system complexity. |

| Implementation Cost | High upfront investment with cost benefits in long-term operation. | Moderate to high, scalable depending on system integration extent. |

| Use Cases | Mass production of electronics, automotive parts. | Smart factories, predictive maintenance, customized manufacturing. |

| Data Utilization | Large volumes of sensor and operational data for automation control. | Real-time data processing for adaptive, fault-tolerant manufacturing. |

Which is better?

Dark factories maximize efficiency by operating fully automated production lines without human intervention, reducing labor costs and minimizing errors. Cyber-physical systems integrate computing, networking, and physical processes, enabling real-time monitoring, adaptive control, and enhanced flexibility in manufacturing environments. Manufacturing facilities leveraging cyber-physical systems typically achieve greater scalability and resilience compared to fully autonomous dark factories.

Connection

Dark factories leverage cyber-physical systems (CPS) to enable fully automated manufacturing processes without human intervention, utilizing sensors, robotics, and AI for real-time monitoring and control. Cyber-physical systems integrate physical production machinery with digital networks, facilitating data exchange and predictive maintenance that drives the efficiency of dark factory operations. This connection enhances production speed, precision, and reduces operational costs by minimizing human error and downtime.

Key Terms

**Cyber-Physical Systems:**

Cyber-Physical Systems (CPS) integrate computation, networking, and physical processes through embedded sensors and actuators to enable real-time monitoring and control in industrial environments. Unlike dark factories, which emphasize fully automated production without human intervention, CPS focus on enhancing human-machine collaboration, improving system resilience, and enabling adaptive manufacturing processes. Explore in-depth how Cyber-Physical Systems transform modern industry by visiting our detailed analysis.

Sensors and Actuators

Cyber-Physical Systems (CPS) integrate sensors and actuators to create real-time feedback loops that enhance automation, while dark factories utilize these components for fully autonomous operations in environments without human intervention. Sensors in CPS continuously monitor physical processes, and actuators execute precise control actions, enabling adaptive and intelligent manufacturing. Explore how advanced sensor-actuator networks drive innovation in industry 4.0 by learning more about their roles in CPS and dark factories.

Real-time Data Integration

Cyber-physical systems (CPS) leverage real-time data integration by connecting physical processes with computational resources, enabling dynamic monitoring and control essential for smart manufacturing. Dark factories rely heavily on real-time data integration from CPS to automate production without human intervention, optimizing efficiency and responsiveness. Explore deeper into how real-time data integration transforms manufacturing through CPS and dark factory innovations.

Source and External Links

10 Examples of Cyber-Physical Systems | Claroty - Cyber-physical systems are engineered platforms integrating computation, control, networking, and analytics with physical environments, playing a transformative role across industries like manufacturing and healthcare by enabling real-time integration between the cyber and physical worlds.

Cyber-Physical Systems (CPS) Explained - Splunk - CPS are systems that model, automate, and control physical mechanisms in a digital environment, deeply intertwining physical and digital behaviors to allow real-time control and simulation, integral to Industry 4.0 and advanced manufacturing processes.

Cyber-Physical Systems - a Concept Map - Ptolemy Project - CPS involve integration of computation, networking, and physical processes with feedback loops, focusing on combining abstractions from physical dynamics and computing to create a cohesive engineering discipline with broad societal and economic impact.

dowidth.com

dowidth.com