Adaptive machining improves CNC machining by using real-time sensor feedback and advanced algorithms to adjust tool paths dynamically, enhancing precision and reducing material waste. CNC machining relies on pre-programmed instructions to execute fixed tool movements, making it highly efficient for repetitive tasks but less flexible to changes during production. Explore the benefits and applications of adaptive machining compared to traditional CNC processes to optimize your manufacturing workflow.

Why it is important

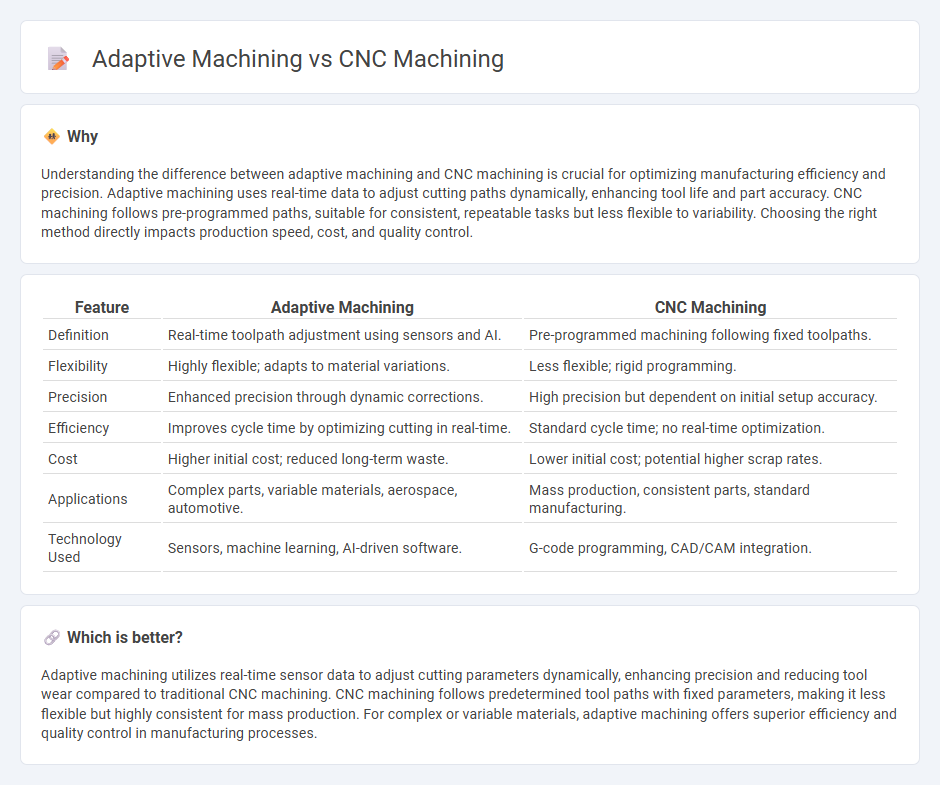

Understanding the difference between adaptive machining and CNC machining is crucial for optimizing manufacturing efficiency and precision. Adaptive machining uses real-time data to adjust cutting paths dynamically, enhancing tool life and part accuracy. CNC machining follows pre-programmed paths, suitable for consistent, repeatable tasks but less flexible to variability. Choosing the right method directly impacts production speed, cost, and quality control.

Comparison Table

| Feature | Adaptive Machining | CNC Machining |

|---|---|---|

| Definition | Real-time toolpath adjustment using sensors and AI. | Pre-programmed machining following fixed toolpaths. |

| Flexibility | Highly flexible; adapts to material variations. | Less flexible; rigid programming. |

| Precision | Enhanced precision through dynamic corrections. | High precision but dependent on initial setup accuracy. |

| Efficiency | Improves cycle time by optimizing cutting in real-time. | Standard cycle time; no real-time optimization. |

| Cost | Higher initial cost; reduced long-term waste. | Lower initial cost; potential higher scrap rates. |

| Applications | Complex parts, variable materials, aerospace, automotive. | Mass production, consistent parts, standard manufacturing. |

| Technology Used | Sensors, machine learning, AI-driven software. | G-code programming, CAD/CAM integration. |

Which is better?

Adaptive machining utilizes real-time sensor data to adjust cutting parameters dynamically, enhancing precision and reducing tool wear compared to traditional CNC machining. CNC machining follows predetermined tool paths with fixed parameters, making it less flexible but highly consistent for mass production. For complex or variable materials, adaptive machining offers superior efficiency and quality control in manufacturing processes.

Connection

Adaptive machining and CNC machining are interconnected through advanced computer numerical control systems that enable real-time adjustments in tool paths and cutting parameters during the manufacturing process. CNC machining provides the precise automation framework, while adaptive machining enhances efficiency by continuously optimizing cutting conditions based on sensor feedback and material properties. This integration leads to improved surface finish, reduced tool wear, and higher overall productivity in manufacturing operations.

Key Terms

Precision

CNC machining offers high precision through programmed tool paths that ensure consistent, repeatable results on complex geometries. Adaptive machining enhances precision by continuously adjusting cutting parameters in real-time based on sensor feedback, reducing tool wear and improving surface finish. Explore the latest advancements in precision machining to understand how adaptive technology is transforming manufacturing accuracy.

Flexibility

CNC machining offers precise control through predefined programs but is limited in adapting to real-time changes in material or tool conditions. Adaptive machining utilizes sensor feedback and real-time data to adjust cutting parameters dynamically, enhancing flexibility and reducing scrap rates. Explore the benefits of adaptive machining for your manufacturing processes and improve operational efficiency.

Automation

CNC machining offers precise control through pre-programmed instructions, while adaptive machining enhances automation by dynamically adjusting cutting parameters in real-time based on sensor feedback. Adaptive machining improves efficiency, reduces tool wear, and enables smarter handling of complex geometries compared to traditional CNC processes. Explore how integrating adaptive technologies can transform your automated manufacturing workflow.

Source and External Links

Online CNC Machining Service | Get a Quote - CNC machining is an automated, subtractive process that transforms solid material blocks into precise parts using computer-controlled end mills, ideal for both prototyping and production in industries like aerospace, medical, and automotive.

All About CNC Machining and How It Works - CNC machining creates parts by removing material from a workpiece based on instructions from G-code generated from CAD models, with operations automated and controlled by computer for high precision and repeatability.

What is CNC Machining? - CNC machining uses computerized controls to operate tools like lathes, mills, and drills, enabling highly automated and accurate manufacturing processes.

dowidth.com

dowidth.com