Smart dust technology enables real-time monitoring of manufacturing processes through networks of tiny, wireless sensors that provide precise data on equipment and environmental conditions. Manufacturing Execution Systems (MES) integrate this data to optimize production workflows, enhance quality control, and improve overall plant efficiency by bridging the gap between enterprise resource planning (ERP) and operational technology (OT). Explore how combining smart dust with MES can revolutionize manufacturing operations and boost productivity.

Why it is important

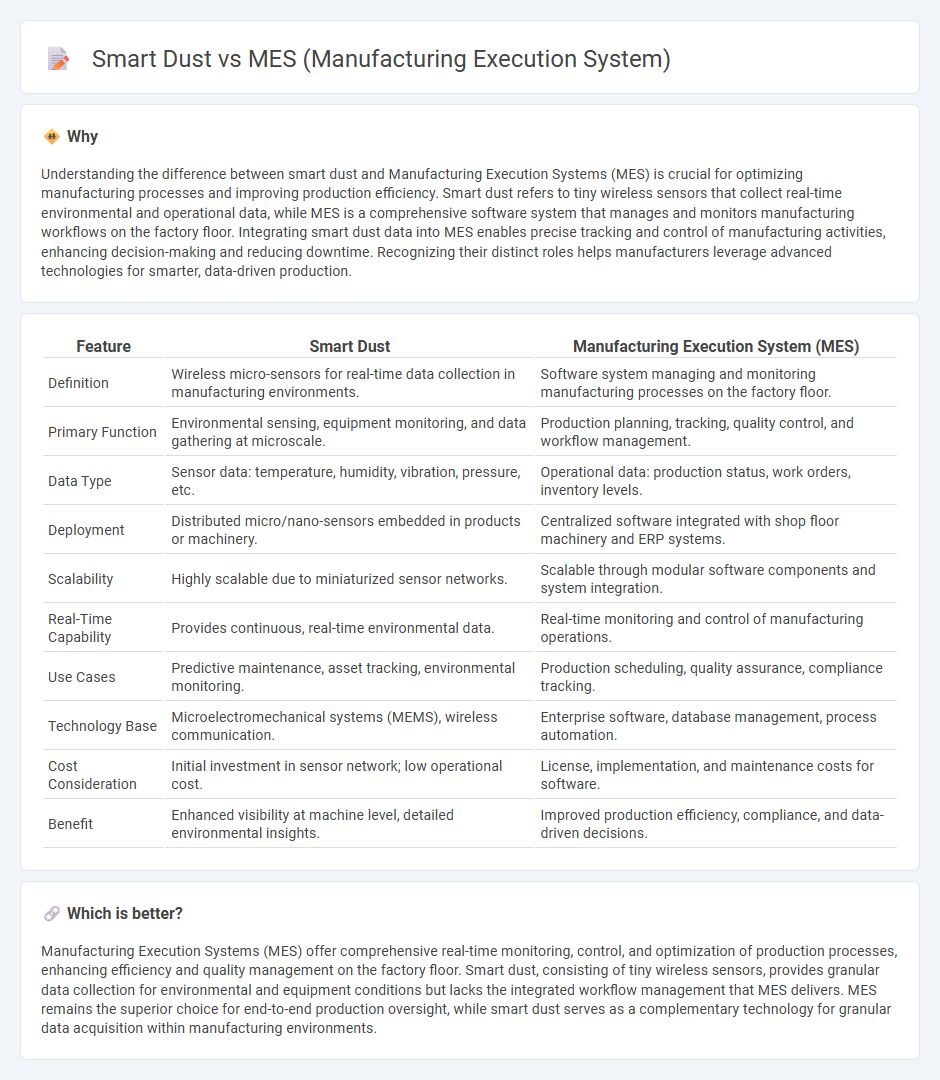

Understanding the difference between smart dust and Manufacturing Execution Systems (MES) is crucial for optimizing manufacturing processes and improving production efficiency. Smart dust refers to tiny wireless sensors that collect real-time environmental and operational data, while MES is a comprehensive software system that manages and monitors manufacturing workflows on the factory floor. Integrating smart dust data into MES enables precise tracking and control of manufacturing activities, enhancing decision-making and reducing downtime. Recognizing their distinct roles helps manufacturers leverage advanced technologies for smarter, data-driven production.

Comparison Table

| Feature | Smart Dust | Manufacturing Execution System (MES) |

|---|---|---|

| Definition | Wireless micro-sensors for real-time data collection in manufacturing environments. | Software system managing and monitoring manufacturing processes on the factory floor. |

| Primary Function | Environmental sensing, equipment monitoring, and data gathering at microscale. | Production planning, tracking, quality control, and workflow management. |

| Data Type | Sensor data: temperature, humidity, vibration, pressure, etc. | Operational data: production status, work orders, inventory levels. |

| Deployment | Distributed micro/nano-sensors embedded in products or machinery. | Centralized software integrated with shop floor machinery and ERP systems. |

| Scalability | Highly scalable due to miniaturized sensor networks. | Scalable through modular software components and system integration. |

| Real-Time Capability | Provides continuous, real-time environmental data. | Real-time monitoring and control of manufacturing operations. |

| Use Cases | Predictive maintenance, asset tracking, environmental monitoring. | Production scheduling, quality assurance, compliance tracking. |

| Technology Base | Microelectromechanical systems (MEMS), wireless communication. | Enterprise software, database management, process automation. |

| Cost Consideration | Initial investment in sensor network; low operational cost. | License, implementation, and maintenance costs for software. |

| Benefit | Enhanced visibility at machine level, detailed environmental insights. | Improved production efficiency, compliance, and data-driven decisions. |

Which is better?

Manufacturing Execution Systems (MES) offer comprehensive real-time monitoring, control, and optimization of production processes, enhancing efficiency and quality management on the factory floor. Smart dust, consisting of tiny wireless sensors, provides granular data collection for environmental and equipment conditions but lacks the integrated workflow management that MES delivers. MES remains the superior choice for end-to-end production oversight, while smart dust serves as a complementary technology for granular data acquisition within manufacturing environments.

Connection

Smart dust technology enhances Manufacturing Execution Systems (MES) by providing real-time, granular data through distributed micro-sensors that monitor equipment performance, environmental conditions, and process variables. This integration enables MES platforms to optimize production workflows, predict maintenance needs, and increase overall operational efficiency by leveraging precise, continuous data streams. Implementation of smart dust within MES frameworks supports advanced analytics and dynamic decision-making, driving Industry 4.0 transformation in manufacturing environments.

Key Terms

Real-time Production Monitoring

Manufacturing Execution Systems (MES) provide comprehensive real-time production monitoring by integrating data from machines, operators, and workflows to optimize manufacturing efficiency and traceability. Smart dust consists of tiny wireless sensors dispersed across the production floor, capturing hyper-local environmental and operational data with high precision and low latency. Explore how combining MES with smart dust technology can revolutionize real-time production monitoring and control.

Wireless Sensor Networks

MES (Manufacturing Execution System) integrates real-time data from wireless sensor networks (WSNs) to optimize production processes, offering comprehensive control over manufacturing operations. Smart dust consists of tiny, wireless sensor nodes that collect and transmit environmental and operational data, enabling granular monitoring and predictive maintenance within industrial settings. Explore how wireless sensor networks transform MES efficiency through smart dust applications for advanced manufacturing insights.

Data Integration

MES (Manufacturing Execution System) centralizes real-time production data, enabling seamless integration between shop floor processes and enterprise systems to optimize manufacturing efficiency. Smart dust consists of tiny, wireless sensors that collect granular environmental and operational data, enhancing data granularity and situational awareness across the production environment. Explore how combining MES and smart dust technologies revolutionizes data integration for smarter, more responsive manufacturing.

Source and External Links

Manufacturing Execution System - Wikipedia - A software system used to track and document the transformation of raw materials into finished goods, providing real-time data to enhance production operations.

What is a Manufacturing Execution System (MES)? - IBM - An MES serves as a bridge between enterprise planning and actual manufacturing operations, providing real-time visibility and control over production processes.

The MES Beginners Guide - Rockwell Automation - A software system that tracks real-time data on the production cycle, connecting and controlling machines and data flows on the factory floor.

dowidth.com

dowidth.com