Industrial edge computing enhances manufacturing operations by processing data closer to production machinery, reducing latency and enabling real-time analytics unlike traditional SCADA systems that rely on centralized control. Edge computing supports faster decision-making and predictive maintenance through distributed intelligence, improving operational efficiency and minimizing downtime on the factory floor. Explore how integrating industrial edge computing with SCADA can revolutionize your manufacturing processes.

Why it is important

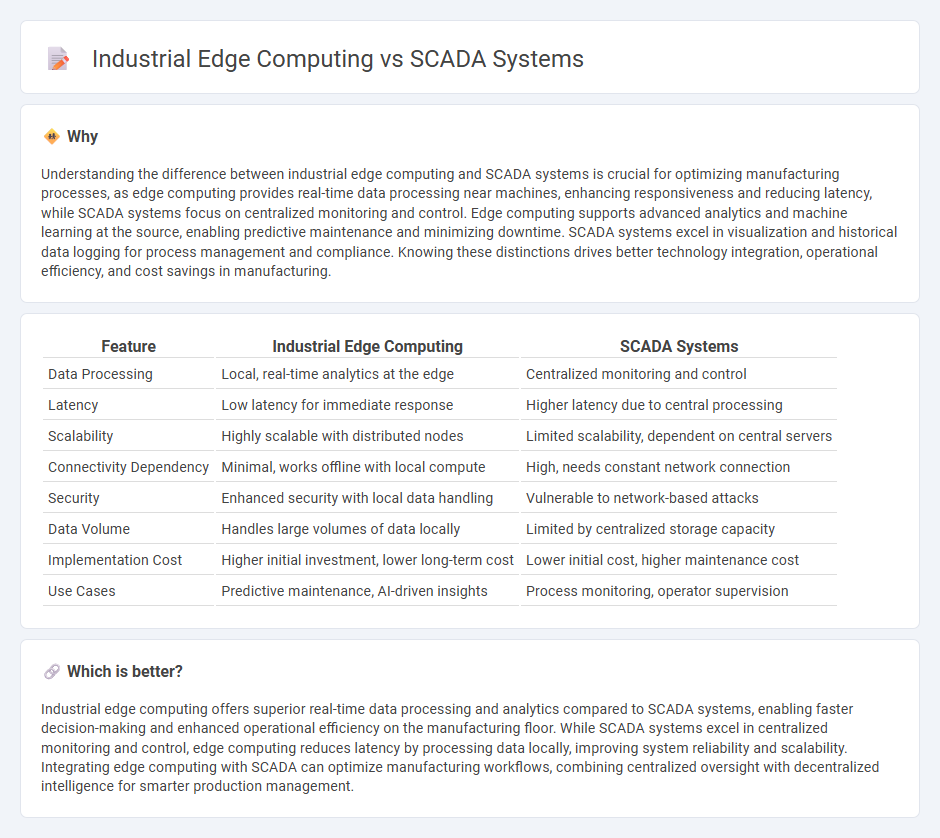

Understanding the difference between industrial edge computing and SCADA systems is crucial for optimizing manufacturing processes, as edge computing provides real-time data processing near machines, enhancing responsiveness and reducing latency, while SCADA systems focus on centralized monitoring and control. Edge computing supports advanced analytics and machine learning at the source, enabling predictive maintenance and minimizing downtime. SCADA systems excel in visualization and historical data logging for process management and compliance. Knowing these distinctions drives better technology integration, operational efficiency, and cost savings in manufacturing.

Comparison Table

| Feature | Industrial Edge Computing | SCADA Systems |

|---|---|---|

| Data Processing | Local, real-time analytics at the edge | Centralized monitoring and control |

| Latency | Low latency for immediate response | Higher latency due to central processing |

| Scalability | Highly scalable with distributed nodes | Limited scalability, dependent on central servers |

| Connectivity Dependency | Minimal, works offline with local compute | High, needs constant network connection |

| Security | Enhanced security with local data handling | Vulnerable to network-based attacks |

| Data Volume | Handles large volumes of data locally | Limited by centralized storage capacity |

| Implementation Cost | Higher initial investment, lower long-term cost | Lower initial cost, higher maintenance cost |

| Use Cases | Predictive maintenance, AI-driven insights | Process monitoring, operator supervision |

Which is better?

Industrial edge computing offers superior real-time data processing and analytics compared to SCADA systems, enabling faster decision-making and enhanced operational efficiency on the manufacturing floor. While SCADA systems excel in centralized monitoring and control, edge computing reduces latency by processing data locally, improving system reliability and scalability. Integrating edge computing with SCADA can optimize manufacturing workflows, combining centralized oversight with decentralized intelligence for smarter production management.

Connection

Industrial edge computing enhances SCADA systems by processing data locally on manufacturing floors, reducing latency and improving real-time decision-making for automation and control. SCADA systems leverage edge computing to collect, analyze, and visualize operational data from sensors and machinery, enabling predictive maintenance and optimizing production efficiency. This integration supports increased reliability, scalability, and cybersecurity in modern manufacturing environments.

Key Terms

Real-time Data Acquisition

SCADA systems excel in real-time data acquisition by continuously monitoring and controlling industrial processes through centralized control units, ensuring immediate response to operational changes. Industrial edge computing enhances this capability by processing data locally at the source, reducing latency and enabling faster decision-making in environments with high data volumes and connectivity challenges. Explore detailed insights into how these technologies complement each other for optimized industrial automation.

Distributed Processing

SCADA systems primarily rely on centralized processing architectures, where data collected from sensors and field devices is transmitted to a central control room for analysis and decision-making. Industrial edge computing distributes this processing closer to the data source, enabling real-time analytics, reduced latency, and enhanced system resilience by processing data locally at edge devices. Explore how distributed processing transforms industrial automation by visiting our detailed comparison of SCADA systems and industrial edge computing.

Latency

SCADA systems often experience higher latency due to centralized data processing, which can delay real-time decision-making in critical industrial operations. Industrial edge computing minimizes latency by processing data locally at the source, enabling faster response times and enhanced operational efficiency. Explore the benefits and trade-offs of these technologies in latency-sensitive environments to optimize your industrial control strategy.

Source and External Links

What is SCADA system and how does it work? - AVEVA - SCADA systems combine software and hardware to automate control and monitoring of industrial processes through components like RTUs/PLCs, HMIs, communication infrastructure, and databases, enabling real-time process visualization and control.

SCADA - Wikipedia - SCADA is a system used to control and monitor physical processes such as electricity transmission and water distribution, consisting of supervisory computers, RTUs, PLCs, and HMIs, communicating data and control commands across systems.

What is SCADA? Supervisory Control and Data Acquisition - Inductive Automation - SCADA is a software and hardware system allowing industrial control and monitoring by interfacing directly with plant machinery and devices, collecting real-time data, and providing operators insight via HMIs to manage processes efficiently.

dowidth.com

dowidth.com