Biofabrication integrates living cells with biomaterials to create complex tissue structures, revolutionizing regenerative medicine and implantable devices. Electrospinning produces nanofibrous scaffolds through polymer jetting, offering high surface area and tunable porosity essential for tissue engineering and filtration. Explore further to understand how these advanced manufacturing techniques reshape biomedical innovations.

Why it is important

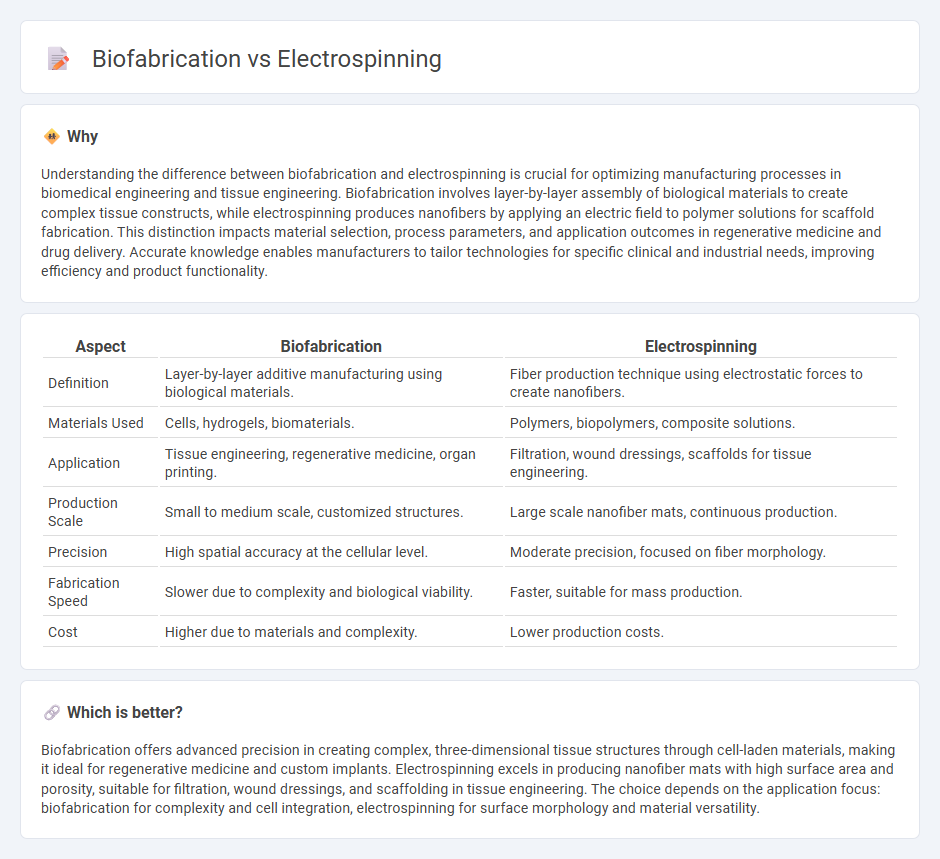

Understanding the difference between biofabrication and electrospinning is crucial for optimizing manufacturing processes in biomedical engineering and tissue engineering. Biofabrication involves layer-by-layer assembly of biological materials to create complex tissue constructs, while electrospinning produces nanofibers by applying an electric field to polymer solutions for scaffold fabrication. This distinction impacts material selection, process parameters, and application outcomes in regenerative medicine and drug delivery. Accurate knowledge enables manufacturers to tailor technologies for specific clinical and industrial needs, improving efficiency and product functionality.

Comparison Table

| Aspect | Biofabrication | Electrospinning |

|---|---|---|

| Definition | Layer-by-layer additive manufacturing using biological materials. | Fiber production technique using electrostatic forces to create nanofibers. |

| Materials Used | Cells, hydrogels, biomaterials. | Polymers, biopolymers, composite solutions. |

| Application | Tissue engineering, regenerative medicine, organ printing. | Filtration, wound dressings, scaffolds for tissue engineering. |

| Production Scale | Small to medium scale, customized structures. | Large scale nanofiber mats, continuous production. |

| Precision | High spatial accuracy at the cellular level. | Moderate precision, focused on fiber morphology. |

| Fabrication Speed | Slower due to complexity and biological viability. | Faster, suitable for mass production. |

| Cost | Higher due to materials and complexity. | Lower production costs. |

Which is better?

Biofabrication offers advanced precision in creating complex, three-dimensional tissue structures through cell-laden materials, making it ideal for regenerative medicine and custom implants. Electrospinning excels in producing nanofiber mats with high surface area and porosity, suitable for filtration, wound dressings, and scaffolding in tissue engineering. The choice depends on the application focus: biofabrication for complexity and cell integration, electrospinning for surface morphology and material versatility.

Connection

Biofabrication integrates living cells and biomaterials to create tissue-like structures, while electrospinning produces nanofibrous scaffolds that mimic the extracellular matrix. Electrospinning is crucial in biofabrication for generating precise, high-surface-area scaffolds that support cell growth and tissue regeneration. This synergy enhances the development of advanced biomaterials for regenerative medicine and tissue engineering applications.

Key Terms

Nanofibers

Electrospinning produces nanofibers by applying a strong electric field to a polymer solution, creating fibers with diameters ranging from tens to hundreds of nanometers, ideal for tissue engineering and drug delivery. Biofabrication encompasses a broader range of techniques, including 3D bioprinting and electrospinning, to create complex biological structures mimicking natural tissues with high precision and biocompatibility. Explore the latest advancements to understand how nanofiber technologies are revolutionizing regenerative medicine.

Scaffold

Electrospinning produces nanofiber scaffolds with high surface area and porosity ideal for tissue engineering, enabling cell attachment and nutrient diffusion. Biofabrication encompasses various techniques like 3D bioprinting and self-assembly to create complex, biomimetic scaffolds with precise architecture and controlled mechanical properties. Explore the advancements in scaffold design to enhance regenerative medicine outcomes.

Biomaterials

Electrospinning creates nanofibrous scaffolds with high surface area and porosity, ideal for biomaterials in tissue engineering and drug delivery. Biofabrication encompasses broader techniques, including 3D bioprinting and cell seeding, enabling precise construction of complex tissue structures using biomaterials like hydrogels and biopolymers. Discover more about how these advanced methods impact biomaterial development and regenerative medicine.

Source and External Links

What is Electrospinning? - Electrospinning is a voltage-driven process where a polymer solution is electrically charged and ejected from a needle to form fine fibers collected on a target, involving formation of a Taylor cone and rapid whipping motion that produces a non-woven fiber mat.

Electrospinning and Electrospun Nanofibers: Methods - Electrospinning uses electrohydrodynamic forces where a charged liquid droplet forms a Taylor cone and ejects a charged jet that elongates, thins, and solidifies into fibers collected on a grounded target, involving four main steps from charging to solidification.

Electrospinning Fundamentals: Optimizing Solution and ... - Electrospinning produces nanofiber scaffolds by overcoming polymer solution surface tension with charge to create a stable jet whose morphology and alignment can be optimized for biomedical applications by adjusting solution and apparatus parameters.

dowidth.com

dowidth.com