Microfactories utilize compact, automated systems to produce goods locally with greater flexibility and reduced overhead compared to traditional factories, which operate on larger scales with extensive machinery and workforce. These microfactories enable quicker adaptation to market changes and customization through advanced technologies like 3D printing and IoT integration. Explore how microfactories are revolutionizing manufacturing efficiency and sustainability in today's industrial landscape.

Why it is important

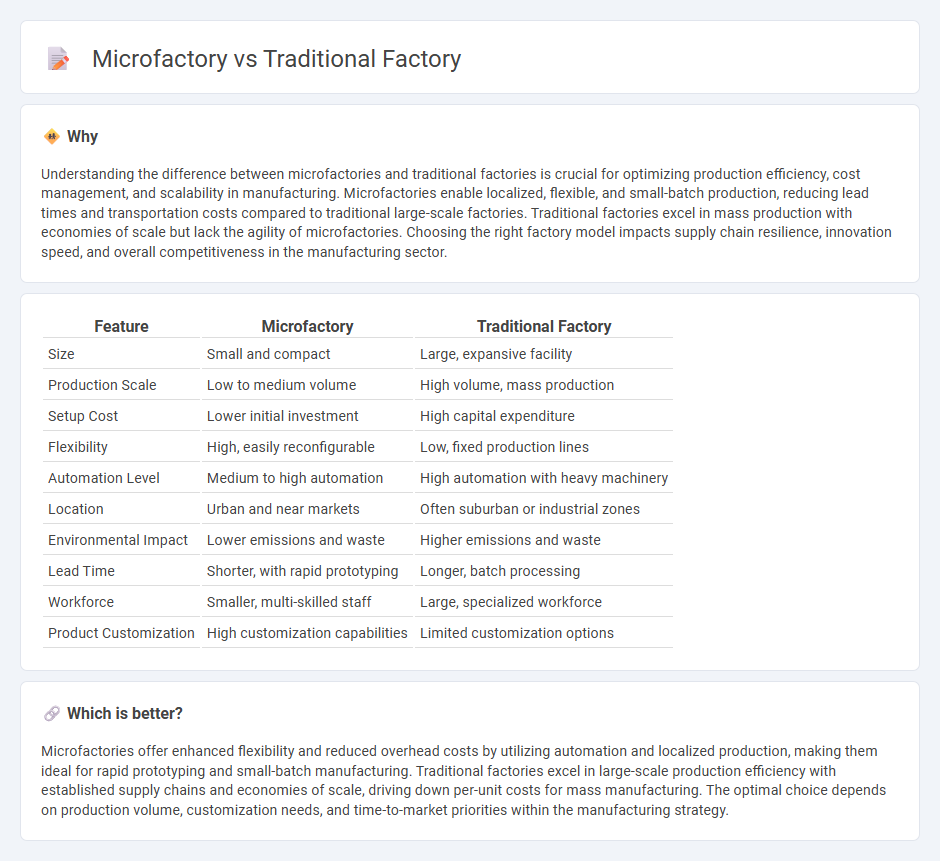

Understanding the difference between microfactories and traditional factories is crucial for optimizing production efficiency, cost management, and scalability in manufacturing. Microfactories enable localized, flexible, and small-batch production, reducing lead times and transportation costs compared to traditional large-scale factories. Traditional factories excel in mass production with economies of scale but lack the agility of microfactories. Choosing the right factory model impacts supply chain resilience, innovation speed, and overall competitiveness in the manufacturing sector.

Comparison Table

| Feature | Microfactory | Traditional Factory |

|---|---|---|

| Size | Small and compact | Large, expansive facility |

| Production Scale | Low to medium volume | High volume, mass production |

| Setup Cost | Lower initial investment | High capital expenditure |

| Flexibility | High, easily reconfigurable | Low, fixed production lines |

| Automation Level | Medium to high automation | High automation with heavy machinery |

| Location | Urban and near markets | Often suburban or industrial zones |

| Environmental Impact | Lower emissions and waste | Higher emissions and waste |

| Lead Time | Shorter, with rapid prototyping | Longer, batch processing |

| Workforce | Smaller, multi-skilled staff | Large, specialized workforce |

| Product Customization | High customization capabilities | Limited customization options |

Which is better?

Microfactories offer enhanced flexibility and reduced overhead costs by utilizing automation and localized production, making them ideal for rapid prototyping and small-batch manufacturing. Traditional factories excel in large-scale production efficiency with established supply chains and economies of scale, driving down per-unit costs for mass manufacturing. The optimal choice depends on production volume, customization needs, and time-to-market priorities within the manufacturing strategy.

Connection

Microfactories and traditional factories are connected through their shared goal of optimizing production efficiency while addressing different scales and customization levels. Microfactories leverage advanced technologies such as automation and IoT to enable localized, flexible manufacturing, complementing the large-scale, high-volume capabilities of traditional factories. This integration allows businesses to balance mass production with agile responses to market demands, enhancing supply chain resilience and reducing lead times.

Key Terms

Mass Production vs. Flexible Production

Traditional factories excel in mass production by utilizing large-scale assembly lines optimized for high-volume, standardized goods, minimizing per-unit costs. Microfactories prioritize flexible production with modular equipment and adaptable workflows, enabling customized outputs and rapid response to market changes. Discover how microfactories transform manufacturing efficiency and agility here.

Large-scale Infrastructure vs. Modular Design

Traditional factories rely on large-scale infrastructure with extensive machinery and centralized production lines, enabling mass production but often resulting in higher operational costs and limited flexibility. Microfactories emphasize modular design, allowing for scalable, customizable manufacturing processes that reduce footprint and enable rapid adaptation to market changes. Explore how shifting from traditional to microfactory models can optimize efficiency and innovation in manufacturing.

High Inventory vs. Just-in-Time Manufacturing

Traditional factories typically operate with high inventory levels to mitigate supply chain disruptions and ensure continuous production, leading to increased storage costs and potential waste. Microfactories emphasize just-in-time manufacturing, producing goods in smaller batches as needed to reduce inventory expenses and enhance responsiveness to market demands. Explore the advantages and challenges of each manufacturing approach to optimize your production strategy.

Source and External Links

From Traditional to Smart: The Evolution of Factories in Manufacturing - Traditional factories rely on manual labor and mechanical processes, with operations following a linear series of steps from raw material procurement to finished product distribution, leading to inefficiencies and quality inconsistencies due to limited automation.

Factory - Wikipedia - Traditional factories emerged in the late 18th century as large-scale, mechanized facilities that replaced artisan workshops, using technologies like steam engines and, later, electric motors to enable mass production and more efficient layouts.

Traditional manufacturing factory vs. smart factory - In traditional factories, processes are manual and isolated, with limited integration between systems, minimal data for decision-making, and fixed production lines that require physical reconfiguration for changes.

dowidth.com

dowidth.com