Lights out factories exemplify fully automated production environments operating without human intervention, significantly reducing labor costs and increasing efficiency. Green manufacturing focuses on sustainable practices that minimize environmental impact through energy-efficient processes, waste reduction, and the use of renewable materials. Explore the benefits and challenges of integrating lights out automation with green manufacturing to advance eco-friendly industrial innovation.

Why it is important

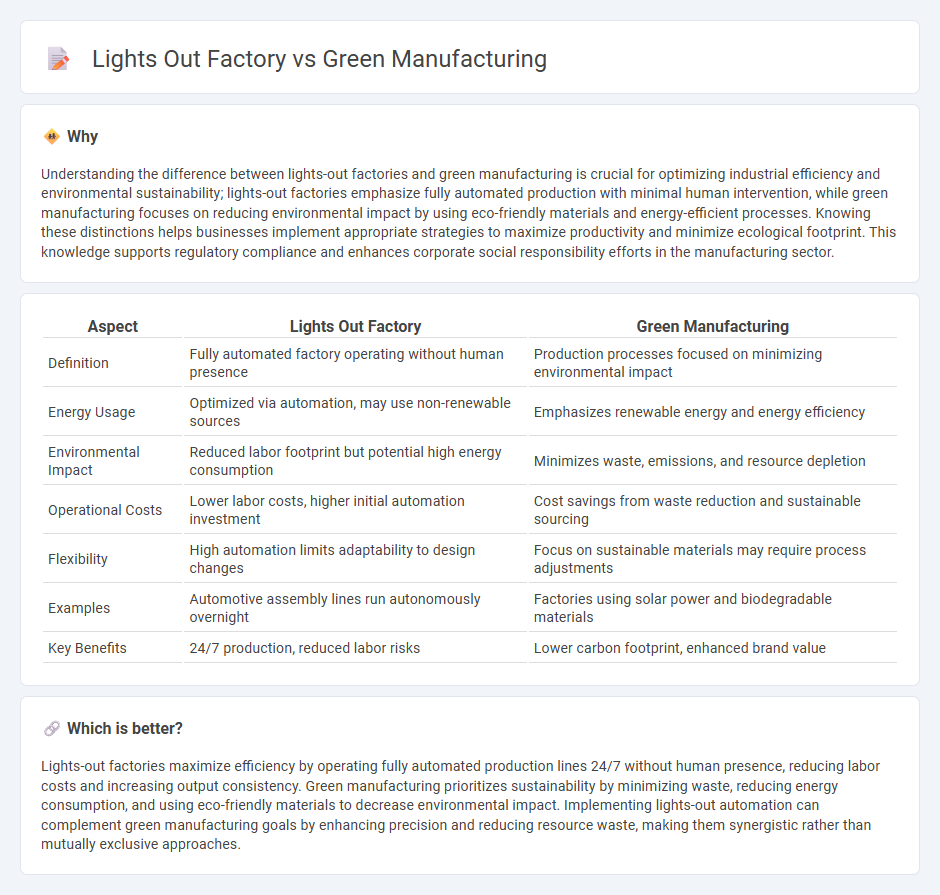

Understanding the difference between lights-out factories and green manufacturing is crucial for optimizing industrial efficiency and environmental sustainability; lights-out factories emphasize fully automated production with minimal human intervention, while green manufacturing focuses on reducing environmental impact by using eco-friendly materials and energy-efficient processes. Knowing these distinctions helps businesses implement appropriate strategies to maximize productivity and minimize ecological footprint. This knowledge supports regulatory compliance and enhances corporate social responsibility efforts in the manufacturing sector.

Comparison Table

| Aspect | Lights Out Factory | Green Manufacturing |

|---|---|---|

| Definition | Fully automated factory operating without human presence | Production processes focused on minimizing environmental impact |

| Energy Usage | Optimized via automation, may use non-renewable sources | Emphasizes renewable energy and energy efficiency |

| Environmental Impact | Reduced labor footprint but potential high energy consumption | Minimizes waste, emissions, and resource depletion |

| Operational Costs | Lower labor costs, higher initial automation investment | Cost savings from waste reduction and sustainable sourcing |

| Flexibility | High automation limits adaptability to design changes | Focus on sustainable materials may require process adjustments |

| Examples | Automotive assembly lines run autonomously overnight | Factories using solar power and biodegradable materials |

| Key Benefits | 24/7 production, reduced labor risks | Lower carbon footprint, enhanced brand value |

Which is better?

Lights-out factories maximize efficiency by operating fully automated production lines 24/7 without human presence, reducing labor costs and increasing output consistency. Green manufacturing prioritizes sustainability by minimizing waste, reducing energy consumption, and using eco-friendly materials to decrease environmental impact. Implementing lights-out automation can complement green manufacturing goals by enhancing precision and reducing resource waste, making them synergistic rather than mutually exclusive approaches.

Connection

Lights-out factories optimize energy consumption by operating with minimal human intervention, aligning with green manufacturing principles that prioritize sustainability and reduced environmental impact. Automated production systems in lights-out factories significantly lower electricity usage and waste, contributing to carbon footprint reduction in manufacturing processes. Integrating advanced robotics and AI technologies enables continuous, energy-efficient operations supporting eco-friendly industrial practices.

Key Terms

**Green Manufacturing:**

Green manufacturing emphasizes sustainable production processes that minimize environmental impact through energy efficiency, waste reduction, and the use of renewable resources. It integrates eco-friendly materials and adopts clean technologies to reduce carbon emissions and conserve natural resources. Explore how green manufacturing drives innovation and sustainability in modern industry.

Sustainability

Green manufacturing emphasizes reducing environmental impact through sustainable practices like energy efficiency, waste minimization, and use of renewable resources. Lights out factories prioritize automation to run with minimal human intervention, often enhancing energy savings and operational efficiency by operating 24/7 without lighting needs. Explore detailed comparisons to understand how these approaches align with sustainability goals.

Energy Efficiency

Green manufacturing emphasizes reducing energy consumption through sustainable processes, eco-friendly materials, and waste minimization to lower the overall environmental impact. Lights-out factories maximize energy efficiency by automating production with minimal human intervention, reducing energy use during off-peak hours and optimizing machine operation. Explore the innovative strategies driving energy efficiency in both green manufacturing and lights-out factories.

Source and External Links

What Is Green Manufacturing? - IBM - Green manufacturing focuses on producing products by reducing carbon footprint, minimizing environmental impacts, conserving energy, and using renewable resources and efficient technologies, all while benefiting businesses through cost savings and regulatory compliance.

What is Green Manufacturing? (Plus 5 Steps to a Greener Future) - Green manufacturing is about minimizing environmental impact and maximizing resource efficiency through eco-friendly processes, such as adopting lean manufacturing and continuous improvement to reduce waste and energy use.

Green Manufacturing: The Business Benefits of Sustainability - Green manufacturing entails reducing environmental pollutants and natural resources usage, which helps companies lower costs and energy consumption while improving productivity and sustainability.

dowidth.com

dowidth.com