Machine vision inspection utilizes advanced cameras and image processing algorithms to detect defects and ensure quality control in manufacturing processes, providing high-speed, non-contact evaluation of products. Automated Optical Inspection (AOI) specifically focuses on using optical imaging to identify surface defects and verify component placements, commonly applied in electronics manufacturing for printed circuit board (PCB) inspection. Explore the differences and benefits of these technologies to enhance production efficiency and product reliability.

Why it is important

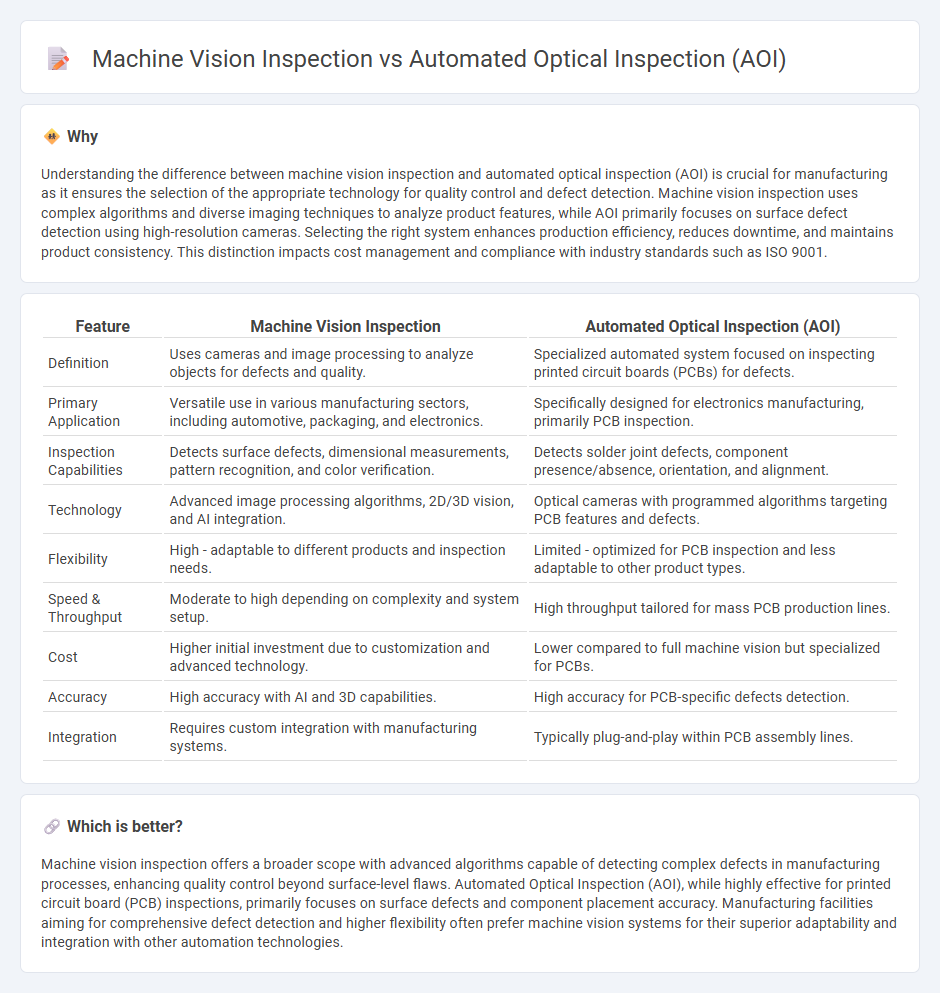

Understanding the difference between machine vision inspection and automated optical inspection (AOI) is crucial for manufacturing as it ensures the selection of the appropriate technology for quality control and defect detection. Machine vision inspection uses complex algorithms and diverse imaging techniques to analyze product features, while AOI primarily focuses on surface defect detection using high-resolution cameras. Selecting the right system enhances production efficiency, reduces downtime, and maintains product consistency. This distinction impacts cost management and compliance with industry standards such as ISO 9001.

Comparison Table

| Feature | Machine Vision Inspection | Automated Optical Inspection (AOI) |

|---|---|---|

| Definition | Uses cameras and image processing to analyze objects for defects and quality. | Specialized automated system focused on inspecting printed circuit boards (PCBs) for defects. |

| Primary Application | Versatile use in various manufacturing sectors, including automotive, packaging, and electronics. | Specifically designed for electronics manufacturing, primarily PCB inspection. |

| Inspection Capabilities | Detects surface defects, dimensional measurements, pattern recognition, and color verification. | Detects solder joint defects, component presence/absence, orientation, and alignment. |

| Technology | Advanced image processing algorithms, 2D/3D vision, and AI integration. | Optical cameras with programmed algorithms targeting PCB features and defects. |

| Flexibility | High - adaptable to different products and inspection needs. | Limited - optimized for PCB inspection and less adaptable to other product types. |

| Speed & Throughput | Moderate to high depending on complexity and system setup. | High throughput tailored for mass PCB production lines. |

| Cost | Higher initial investment due to customization and advanced technology. | Lower compared to full machine vision but specialized for PCBs. |

| Accuracy | High accuracy with AI and 3D capabilities. | High accuracy for PCB-specific defects detection. |

| Integration | Requires custom integration with manufacturing systems. | Typically plug-and-play within PCB assembly lines. |

Which is better?

Machine vision inspection offers a broader scope with advanced algorithms capable of detecting complex defects in manufacturing processes, enhancing quality control beyond surface-level flaws. Automated Optical Inspection (AOI), while highly effective for printed circuit board (PCB) inspections, primarily focuses on surface defects and component placement accuracy. Manufacturing facilities aiming for comprehensive defect detection and higher flexibility often prefer machine vision systems for their superior adaptability and integration with other automation technologies.

Connection

Machine vision inspection and automated optical inspection (AOI) are interconnected technologies that enhance manufacturing quality control by using high-resolution cameras and image processing algorithms to detect defects in products and components. AOI is a specific application of machine vision tailored for inspecting printed circuit boards (PCBs) and electronics, enabling real-time identification of soldering faults, component misplacements, and surface defects. Integrating these technologies optimizes production efficiency, reduces human error, and ensures consistent product quality.

Key Terms

Image Processing Algorithms

Automated Optical Inspection (AOI) and Machine Vision Inspection both rely heavily on sophisticated image processing algorithms to detect defects and ensure product quality. AOI typically uses rule-based algorithms designed for specific inspection tasks, such as pattern matching and defect location on printed circuit boards (PCBs), while machine vision incorporates advanced techniques like deep learning and neural networks for more adaptive, real-time analysis. Explore how evolving image processing algorithms enhance inspection accuracy and speed across these technologies.

Defect Detection

Automated Optical Inspection (AOI) uses high-resolution cameras and lighting to capture detailed images of printed circuit boards, focusing on identifying surface defects such as solder joint issues, misalignments, and missing components with high precision. Machine vision inspection integrates AI-driven algorithms and advanced imaging techniques to analyze complex patterns and defects across diverse manufacturing processes, enabling real-time adaptive defect classification beyond simple visual anomalies. Explore the latest advancements in AOI and machine vision to enhance your defect detection capabilities and improve quality control.

Inspection Flexibility

Automated Optical Inspection (AOI) excels in high-speed, specific defect detection on printed circuit boards with predetermined criteria, providing consistent precision but limited adaptability to varying inspection tasks. Machine vision inspection offers greater flexibility by employing advanced algorithms and multiple imaging techniques, allowing customization for diverse applications beyond fixed defect types. Explore deeper insights on how inspection flexibility impacts quality control effectiveness in manufacturing processes.

Source and External Links

Automated optical inspection - Automated optical inspection (AOI) is an automated visual inspection method used primarily in printed circuit board (PCB) manufacturing to detect defects like missing components, solder issues, and alignment problems at various production stages without physical contact.

What is AOI (Automated Optical Inspection) - AOI systems consist mainly of an optical system (including light sources, lenses, and cameras) and software algorithms to capture and analyze images to identify defects in manufacturing, with modern systems using LED lighting and 2D or 3D cameras.

Automated Optical Inspection Systems (AOI systems) - Advanced AOI systems provide fully automated 3D inspection with high-speed and high-accuracy capabilities for various industries, supporting customizable optics, illumination, and measurement resolutions down to 0.1 micron for detailed defect detection.

dowidth.com

dowidth.com