Soft robotics offers enhanced flexibility and adaptability through compliant materials, making it ideal for delicate and precise manufacturing tasks. Hydraulic systems deliver powerful, high-force performance suitable for heavy-duty applications and precise control under extreme loads. Explore the differences between these technologies to optimize manufacturing processes.

Why it is important

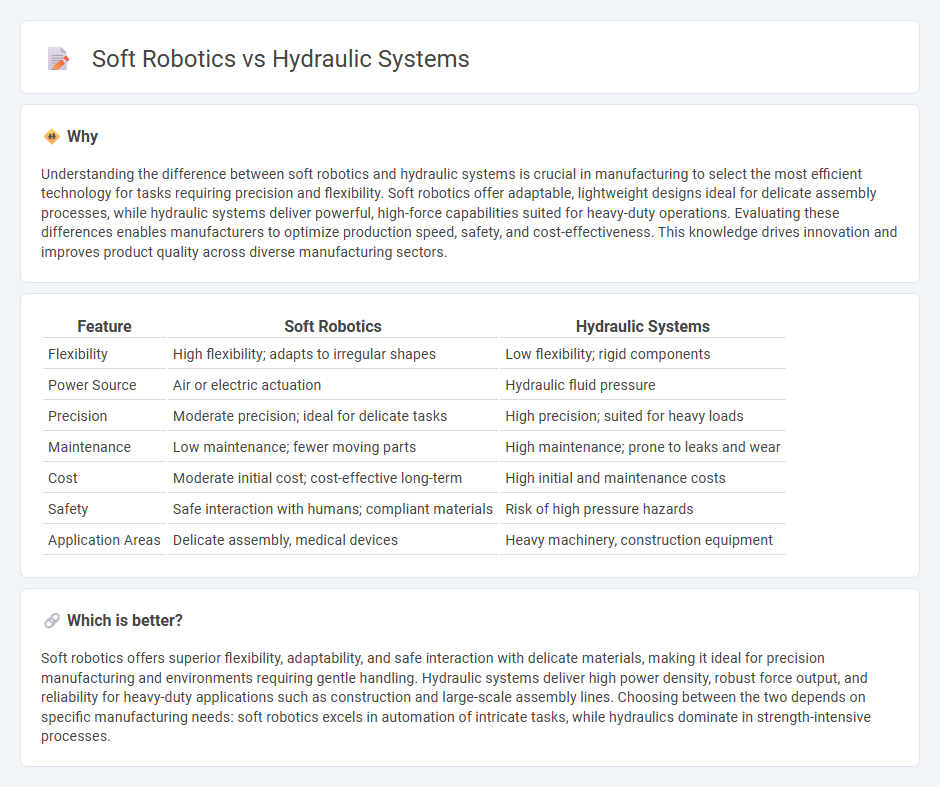

Understanding the difference between soft robotics and hydraulic systems is crucial in manufacturing to select the most efficient technology for tasks requiring precision and flexibility. Soft robotics offer adaptable, lightweight designs ideal for delicate assembly processes, while hydraulic systems deliver powerful, high-force capabilities suited for heavy-duty operations. Evaluating these differences enables manufacturers to optimize production speed, safety, and cost-effectiveness. This knowledge drives innovation and improves product quality across diverse manufacturing sectors.

Comparison Table

| Feature | Soft Robotics | Hydraulic Systems |

|---|---|---|

| Flexibility | High flexibility; adapts to irregular shapes | Low flexibility; rigid components |

| Power Source | Air or electric actuation | Hydraulic fluid pressure |

| Precision | Moderate precision; ideal for delicate tasks | High precision; suited for heavy loads |

| Maintenance | Low maintenance; fewer moving parts | High maintenance; prone to leaks and wear |

| Cost | Moderate initial cost; cost-effective long-term | High initial and maintenance costs |

| Safety | Safe interaction with humans; compliant materials | Risk of high pressure hazards |

| Application Areas | Delicate assembly, medical devices | Heavy machinery, construction equipment |

Which is better?

Soft robotics offers superior flexibility, adaptability, and safe interaction with delicate materials, making it ideal for precision manufacturing and environments requiring gentle handling. Hydraulic systems deliver high power density, robust force output, and reliability for heavy-duty applications such as construction and large-scale assembly lines. Choosing between the two depends on specific manufacturing needs: soft robotics excels in automation of intricate tasks, while hydraulics dominate in strength-intensive processes.

Connection

Soft robotics integrates hydraulic systems to enable flexible, precise, and powerful movements in manufacturing processes, enhancing automation capabilities. Hydraulic actuators provide the necessary fluid pressure to control soft robotic components, allowing delicate handling and adaptability in assembly lines. This synergy improves efficiency and safety by combining the compliance of soft materials with the strength and reliability of hydraulic power.

Key Terms

Actuators

Hydraulic systems utilize fluid pressure to power actuators, offering high force output and precise control ideal for heavy-duty applications, while soft robotics employ compliant, flexible actuators made from materials like silicone, enabling safer interaction with delicate objects and environments. Hydraulic actuators offer durability and strength, but soft robotic actuators provide adaptability and resilience in unpredictable conditions. Explore the evolving landscape of actuators to understand how these technologies can transform automation and robotics.

Compliance

Hydraulic systems offer precise control and high force output, but often lack the inherent compliance necessary for delicate or adaptive tasks, making them less suitable for environments requiring safe human interaction. Soft robotics leverage flexible materials and structures to achieve superior compliance, enabling safer and more adaptable performance in unstructured settings. Explore the latest advancements in compliant soft robotics for insights into next-generation adaptive systems.

Fluid Power

Hydraulic systems utilize pressurized fluids to generate high force and precise motion, making them ideal for heavy-duty machinery and industrial applications. Soft robotics employs flexible materials and fluid power to create adaptable, safe, and biologically inspired movements, often using pneumatics or hydraulics for actuation. Explore the latest advancements and key differences in fluid power technologies to enhance your understanding of both fields.

Source and External Links

Hydraulic System: 5 Common Examples and Their Applications - Hydraulic systems transmit energy via incompressible fluid, with common types including open-center systems where fluid flows idly and closed-loop systems featuring continuous fluid movement between actuator and pump for precise control.

What Is a Hydraulic System? Definition, Design, and Components - Hydraulic systems use pressurized fluid to transfer mechanical power, relying on pumps to convert mechanical energy into hydraulic energy and actuators like hydraulic motors to convert fluid pressure back to mechanical motion.

8 Common Types of Hydraulic Systems in the Fluid Mechanics - Open loop hydraulic systems circulate fluid through valves and actuators back to the reservoir and are suitable for low pressure, while closed-loop systems recycle fluid between piston pump and motor for high-pressure, compact, and multidirectional applications.

dowidth.com

dowidth.com