Digital twins enable real-time simulation and monitoring of manufacturing processes by creating precise virtual replicas of physical assets, enhancing design accuracy and operational efficiency. Physical prototypes provide tangible models for hands-on testing and validation, essential for assessing material properties and ergonomic factors before full-scale production. Explore how integrating digital twins with physical prototypes can revolutionize product development and reduce time-to-market.

Why it is important

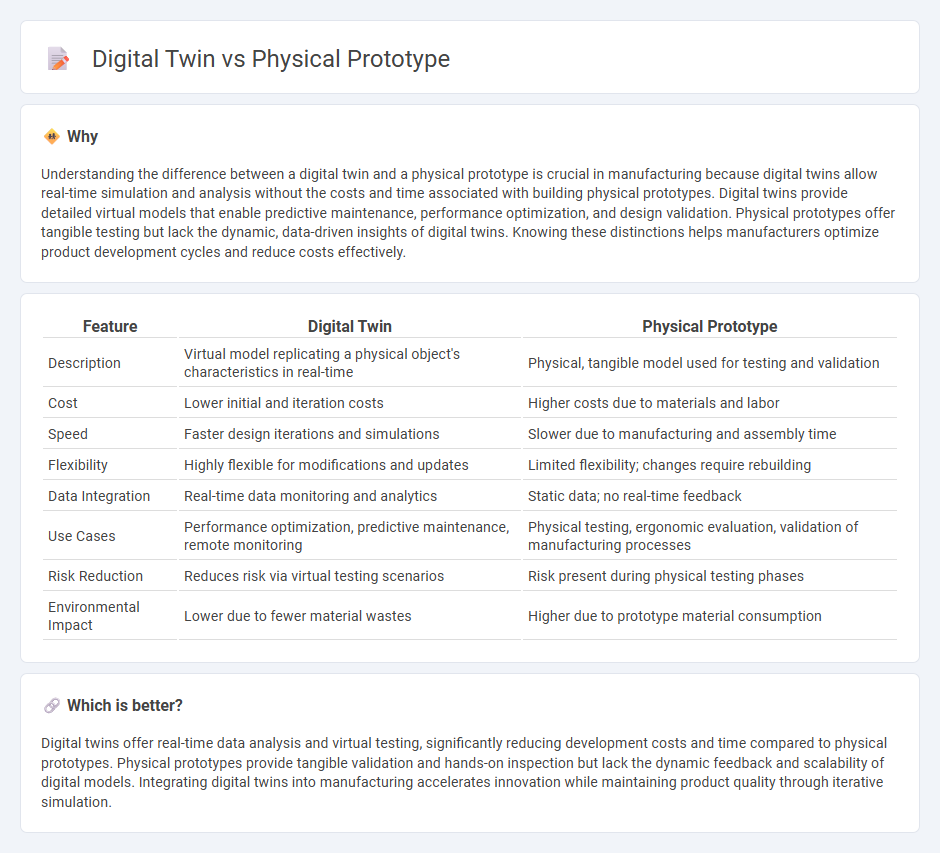

Understanding the difference between a digital twin and a physical prototype is crucial in manufacturing because digital twins allow real-time simulation and analysis without the costs and time associated with building physical prototypes. Digital twins provide detailed virtual models that enable predictive maintenance, performance optimization, and design validation. Physical prototypes offer tangible testing but lack the dynamic, data-driven insights of digital twins. Knowing these distinctions helps manufacturers optimize product development cycles and reduce costs effectively.

Comparison Table

| Feature | Digital Twin | Physical Prototype |

|---|---|---|

| Description | Virtual model replicating a physical object's characteristics in real-time | Physical, tangible model used for testing and validation |

| Cost | Lower initial and iteration costs | Higher costs due to materials and labor |

| Speed | Faster design iterations and simulations | Slower due to manufacturing and assembly time |

| Flexibility | Highly flexible for modifications and updates | Limited flexibility; changes require rebuilding |

| Data Integration | Real-time data monitoring and analytics | Static data; no real-time feedback |

| Use Cases | Performance optimization, predictive maintenance, remote monitoring | Physical testing, ergonomic evaluation, validation of manufacturing processes |

| Risk Reduction | Reduces risk via virtual testing scenarios | Risk present during physical testing phases |

| Environmental Impact | Lower due to fewer material wastes | Higher due to prototype material consumption |

Which is better?

Digital twins offer real-time data analysis and virtual testing, significantly reducing development costs and time compared to physical prototypes. Physical prototypes provide tangible validation and hands-on inspection but lack the dynamic feedback and scalability of digital models. Integrating digital twins into manufacturing accelerates innovation while maintaining product quality through iterative simulation.

Connection

Digital twins create a virtual replica of a physical prototype, enabling real-time simulation and analysis throughout the manufacturing process. This connection allows manufacturers to identify design flaws, optimize performance, and reduce production costs before creating physical models. Integrating digital twins with physical prototypes accelerates product development cycles and enhances precision in manufacturing.

Key Terms

Tangible Model

A physical prototype serves as a tangible model, providing real-world interaction and testing capabilities that help identify design flaws early. In contrast, a digital twin offers a virtual representation with real-time data integration, enabling continuous monitoring and simulation without the need for physical presence. Explore more insights on how tangible models and digital twins complement each other in modern product development.

Virtual Simulation

A physical prototype provides tangible testing of designs, while a digital twin enables real-time virtual simulation of systems, allowing for more precise analysis and optimization without physical constraints. Digital twins integrate IoT data and advanced modeling to predict performance and detect issues before manufacturing. Discover how leveraging virtual simulation through digital twins can revolutionize product development processes.

Real-time Data

A physical prototype provides tangible, real-world testing but lacks continuous real-time data updates, limiting immediate insights into performance under varying conditions. In contrast, a digital twin integrates real-time sensor data, enabling dynamic simulation and instant monitoring of system behaviors, which enhances predictive maintenance and operational efficiency. Explore further to discover how real-time data transforms product development processes.

Source and External Links

Turning Your Engineering Idea into Reality: A Guide to Physical Product Prototyping - Physical product prototyping is the process of creating a preliminary version of a physical product to test its design and functionality, enabling identification of issues and improvements before final production.

Digital vs Physical: Unveiling the Power of Rapid Prototyping in Product Development - Physical prototypes provide critical tactile feedback, functional testing, material validation, and stakeholder engagement, making them essential for validating many aspects of a product's design and user experience.

5 Key Principles In Physical Product Prototype Development - Effective physical prototyping starts with low-fidelity models using quick, inexpensive materials such as cardboard or clay to validate concepts before advancing to higher fidelity prototypes.

dowidth.com

dowidth.com