Microfactories optimize manufacturing by utilizing compact, automated systems that reduce space, energy consumption, and production time compared to traditional factories, which rely on large-scale, labor-intensive processes. These innovative setups enable localized production, rapid prototyping, and greater flexibility in small-batch manufacturing, addressing modern demands for customization and sustainability. Explore how microfactories are redefining manufacturing efficiency and agility in the evolving industrial landscape.

Why it is important

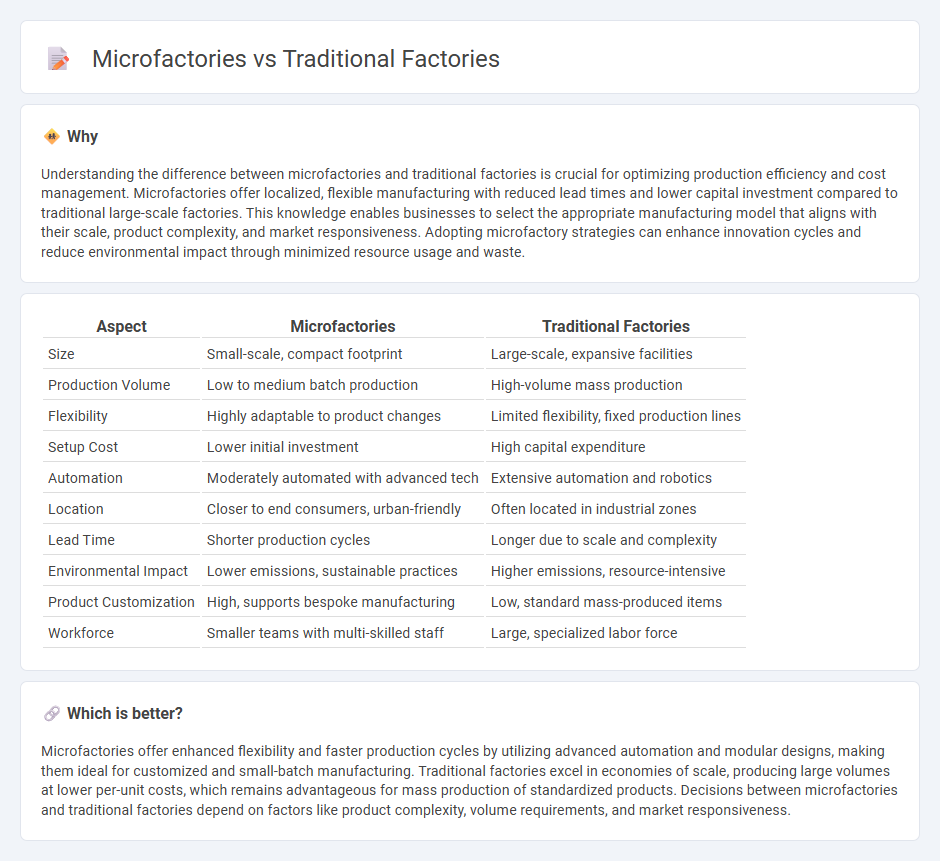

Understanding the difference between microfactories and traditional factories is crucial for optimizing production efficiency and cost management. Microfactories offer localized, flexible manufacturing with reduced lead times and lower capital investment compared to traditional large-scale factories. This knowledge enables businesses to select the appropriate manufacturing model that aligns with their scale, product complexity, and market responsiveness. Adopting microfactory strategies can enhance innovation cycles and reduce environmental impact through minimized resource usage and waste.

Comparison Table

| Aspect | Microfactories | Traditional Factories |

|---|---|---|

| Size | Small-scale, compact footprint | Large-scale, expansive facilities |

| Production Volume | Low to medium batch production | High-volume mass production |

| Flexibility | Highly adaptable to product changes | Limited flexibility, fixed production lines |

| Setup Cost | Lower initial investment | High capital expenditure |

| Automation | Moderately automated with advanced tech | Extensive automation and robotics |

| Location | Closer to end consumers, urban-friendly | Often located in industrial zones |

| Lead Time | Shorter production cycles | Longer due to scale and complexity |

| Environmental Impact | Lower emissions, sustainable practices | Higher emissions, resource-intensive |

| Product Customization | High, supports bespoke manufacturing | Low, standard mass-produced items |

| Workforce | Smaller teams with multi-skilled staff | Large, specialized labor force |

Which is better?

Microfactories offer enhanced flexibility and faster production cycles by utilizing advanced automation and modular designs, making them ideal for customized and small-batch manufacturing. Traditional factories excel in economies of scale, producing large volumes at lower per-unit costs, which remains advantageous for mass production of standardized products. Decisions between microfactories and traditional factories depend on factors like product complexity, volume requirements, and market responsiveness.

Connection

Microfactories and traditional factories are connected through complementary manufacturing processes that enhance overall production efficiency. Microfactories specialize in flexible, small-scale, and localized production using advanced technologies like automation and IoT, while traditional factories focus on large-scale mass production. Integrating microfactories into supply chains optimizes customization and reduces lead times, supporting just-in-time manufacturing and responsive market demands.

Key Terms

Scale of Production

Traditional factories typically operate on a large scale, producing high volumes of standardized products through extensive assembly lines and automation. Microfactories emphasize smaller-scale, flexible production, often tailored for customization and rapid response to local market demands, leveraging advanced technologies like 3D printing and modular setups. Explore the distinct advantages of both systems to understand their impact on efficiency and innovation.

Automation Level

Traditional factories often rely on large-scale, manual labor processes with limited automation integration, resulting in slower production cycles and higher labor costs. Microfactories leverage advanced automation technologies, such as robotics and AI-driven systems, to enhance precision, reduce waste, and enable rapid, flexible manufacturing at a smaller scale. Explore the evolving landscape of factory automation to understand how microfactories are transforming industrial production.

Flexibility

Traditional factories are typically large-scale facilities optimized for mass production with rigid workflows, limiting their ability to quickly adapt to market changes. Microfactories, by contrast, leverage modular designs, advanced automation, and localized production to deliver high flexibility and rapid reconfiguration, meeting customized demands efficiently. Explore the benefits and use cases of microfactories to understand how they reshape modern manufacturing flexibility.

Source and External Links

Factory - Wikipedia - Traditional factories, emerging between 1770 and 1850, replaced artisan shops with mechanized production in industries like textiles, footwear, and machinery, evolving through electrification and automation to improve efficiency and layout flexibility.

Advanced Manufacturing vs. Traditional Manufacturing - SixDe - Traditional manufacturing relies on hierarchical organization and mass production with mostly semi-skilled labor using processes like welding and casting, contrasting with advanced manufacturing's customization and technology use.

Friends or Foes: Additive and Traditional Manufacturing - Traditional manufacturing benefits include high-volume, cost-effective production with strong part consistency but faces drawbacks such as high material waste and inflexibility in design changes.

dowidth.com

dowidth.com