Industrial metaverse integrates augmented reality, digital twin technology, and IoT to create immersive, interconnected virtual environments for manufacturing processes. Digital twins focus on creating real-time, data-driven virtual replicas of physical assets to optimize production and maintenance. Explore how these technologies transform manufacturing innovation and efficiency.

Why it is important

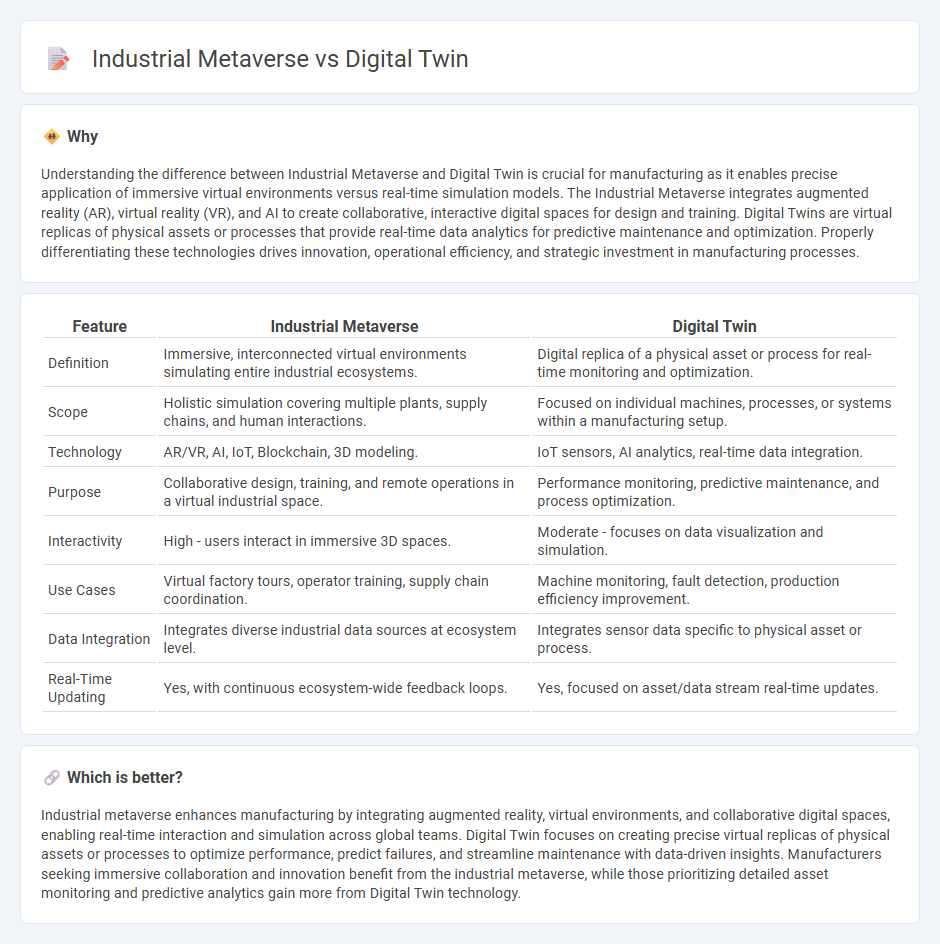

Understanding the difference between Industrial Metaverse and Digital Twin is crucial for manufacturing as it enables precise application of immersive virtual environments versus real-time simulation models. The Industrial Metaverse integrates augmented reality (AR), virtual reality (VR), and AI to create collaborative, interactive digital spaces for design and training. Digital Twins are virtual replicas of physical assets or processes that provide real-time data analytics for predictive maintenance and optimization. Properly differentiating these technologies drives innovation, operational efficiency, and strategic investment in manufacturing processes.

Comparison Table

| Feature | Industrial Metaverse | Digital Twin |

|---|---|---|

| Definition | Immersive, interconnected virtual environments simulating entire industrial ecosystems. | Digital replica of a physical asset or process for real-time monitoring and optimization. |

| Scope | Holistic simulation covering multiple plants, supply chains, and human interactions. | Focused on individual machines, processes, or systems within a manufacturing setup. |

| Technology | AR/VR, AI, IoT, Blockchain, 3D modeling. | IoT sensors, AI analytics, real-time data integration. |

| Purpose | Collaborative design, training, and remote operations in a virtual industrial space. | Performance monitoring, predictive maintenance, and process optimization. |

| Interactivity | High - users interact in immersive 3D spaces. | Moderate - focuses on data visualization and simulation. |

| Use Cases | Virtual factory tours, operator training, supply chain coordination. | Machine monitoring, fault detection, production efficiency improvement. |

| Data Integration | Integrates diverse industrial data sources at ecosystem level. | Integrates sensor data specific to physical asset or process. |

| Real-Time Updating | Yes, with continuous ecosystem-wide feedback loops. | Yes, focused on asset/data stream real-time updates. |

Which is better?

Industrial metaverse enhances manufacturing by integrating augmented reality, virtual environments, and collaborative digital spaces, enabling real-time interaction and simulation across global teams. Digital Twin focuses on creating precise virtual replicas of physical assets or processes to optimize performance, predict failures, and streamline maintenance with data-driven insights. Manufacturers seeking immersive collaboration and innovation benefit from the industrial metaverse, while those prioritizing detailed asset monitoring and predictive analytics gain more from Digital Twin technology.

Connection

The Industrial Metaverse leverages Digital Twin technology by creating virtual replicas of physical manufacturing assets, enabling real-time monitoring and simulation of production processes. This integration enhances predictive maintenance, optimizes supply chain management, and accelerates product development cycles. Digital Twins serve as foundational elements within the Industrial Metaverse, facilitating immersive, data-driven decision-making in smart factories.

Key Terms

Simulation

Digital Twin technology creates precise virtual replicas of physical assets, enabling real-time simulation and predictive maintenance to optimize industrial operations. The Industrial Metaverse expands this concept by integrating interconnected digital environments that support collaborative simulations and immersive experiences across multiple sites. Discover how these advanced simulation tools are revolutionizing industrial processes.

Real-time Data Integration

Digital Twin technology enables precise real-time data integration by creating dynamic virtual replicas of physical assets, enhancing predictive maintenance and operational efficiency. The Industrial Metaverse extends this concept by incorporating immersive 3D environments and collaborative platforms, allowing multiple stakeholders to interact with synchronized real-time data streams across distributed networks. Explore how these innovations revolutionize industrial processes and unlock new potentials in smart manufacturing.

Virtual Collaboration

Digital Twin technology enables precise virtual replication of physical assets, allowing real-time monitoring and simulation to optimize industrial processes. The Industrial Metaverse expands this concept by creating immersive, interactive environments where multiple stakeholders can collaborate virtually across complex systems and workflows. Explore how these innovations transform industrial collaboration by enhancing efficiency and decision-making in connected virtual spaces.

Source and External Links

Definition of a Digital Twin - A digital twin is an integrated data-driven virtual representation of real-world entities and processes, synchronized with the physical counterpart at specified frequency and fidelity.

Digital twin - Wikipedia - A digital twin is a digital model of an actual or intended real-world system, product, or process, used for simulation, integration, testing, monitoring, and maintenance.

What Is a Digital Twin? | IBM - A digital twin is a virtual, real-time updated representation of a physical object or system, used for analysis, simulation, and decision-making across its lifecycle.

dowidth.com

dowidth.com