Soft robotics offers enhanced flexibility and gentle handling suited for delicate items, while traditional pick-and-place machines deliver high-speed precision in repetitive tasks. Advances in soft materials and actuators enable robots to adapt to varied manufacturing processes, reducing product damage and increasing efficiency. Explore the evolving roles of soft robotics and pick-and-place systems in modern manufacturing for optimized productivity.

Why it is important

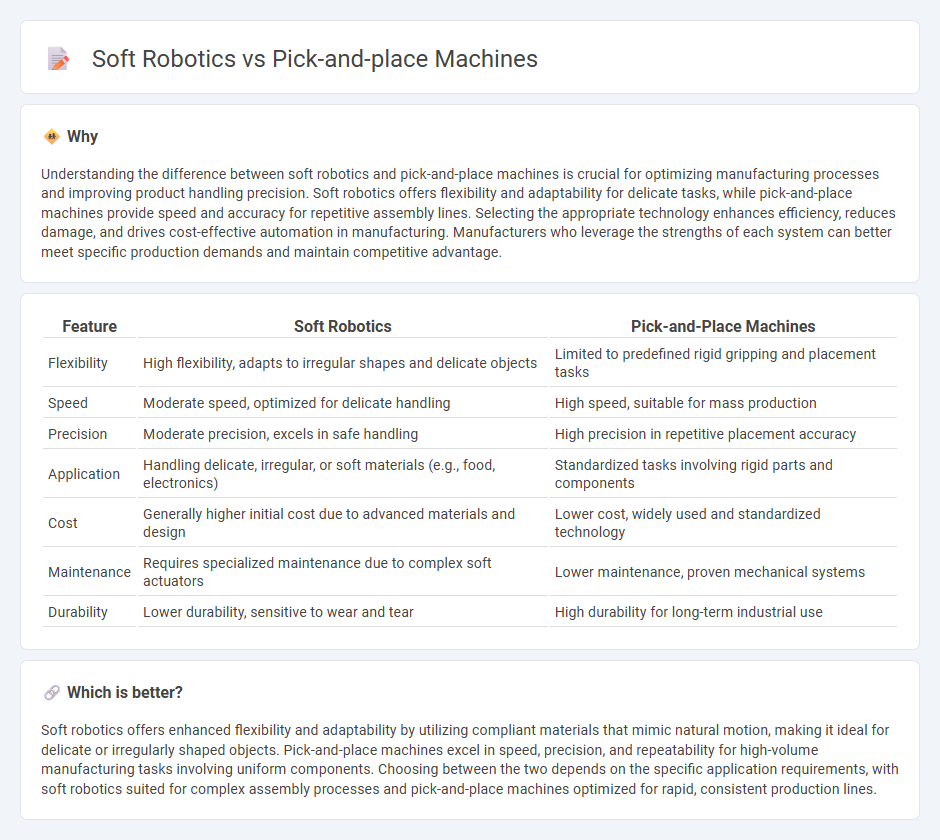

Understanding the difference between soft robotics and pick-and-place machines is crucial for optimizing manufacturing processes and improving product handling precision. Soft robotics offers flexibility and adaptability for delicate tasks, while pick-and-place machines provide speed and accuracy for repetitive assembly lines. Selecting the appropriate technology enhances efficiency, reduces damage, and drives cost-effective automation in manufacturing. Manufacturers who leverage the strengths of each system can better meet specific production demands and maintain competitive advantage.

Comparison Table

| Feature | Soft Robotics | Pick-and-Place Machines |

|---|---|---|

| Flexibility | High flexibility, adapts to irregular shapes and delicate objects | Limited to predefined rigid gripping and placement tasks |

| Speed | Moderate speed, optimized for delicate handling | High speed, suitable for mass production |

| Precision | Moderate precision, excels in safe handling | High precision in repetitive placement accuracy |

| Application | Handling delicate, irregular, or soft materials (e.g., food, electronics) | Standardized tasks involving rigid parts and components |

| Cost | Generally higher initial cost due to advanced materials and design | Lower cost, widely used and standardized technology |

| Maintenance | Requires specialized maintenance due to complex soft actuators | Lower maintenance, proven mechanical systems |

| Durability | Lower durability, sensitive to wear and tear | High durability for long-term industrial use |

Which is better?

Soft robotics offers enhanced flexibility and adaptability by utilizing compliant materials that mimic natural motion, making it ideal for delicate or irregularly shaped objects. Pick-and-place machines excel in speed, precision, and repeatability for high-volume manufacturing tasks involving uniform components. Choosing between the two depends on the specific application requirements, with soft robotics suited for complex assembly processes and pick-and-place machines optimized for rapid, consistent production lines.

Connection

Soft robotics enhances pick-and-place machines by providing flexible, adaptive grippers that handle delicate or irregularly shaped objects with precision, reducing damage and improving efficiency. Integrating soft robotic components allows these machines to operate in complex manufacturing environments, accommodating a wide range of product variations. This synergy advances automation by increasing reliability and expanding the types of materials and items that can be effectively managed on assembly lines.

Key Terms

Precision

Pick-and-place machines deliver high precision through rigid mechanical components and programmed movements, ideal for repetitive tasks requiring consistent accuracy within micrometer tolerances. Soft robotics utilize flexible, adaptive materials and sensors to gently manipulate objects, enhancing precision in handling delicate or irregularly shaped items where traditional rigidity falls short. Explore how the evolving technologies in both fields address diverse precision requirements across various industries.

Flexibility

Pick-and-place machines offer high-speed precision for repetitive tasks but lack the adaptability required for handling diverse or delicate items. Soft robotics provide enhanced flexibility through compliant materials and adaptive grippers, enabling manipulation of irregular shapes and fragile objects with minimal damage. Explore how integrating soft robotics can revolutionize automation by combining speed and flexibility for advanced manufacturing needs.

Throughput

Pick-and-place machines excel in high-throughput applications due to their rapid, precise, and repetitive actions, making them ideal for industries requiring mass production and minimal cycle time. Soft robotics offer greater adaptability and gentle handling, but their throughput is generally lower compared to rigid pick-and-place systems because of slower actuation speeds. Explore how each technology can optimize your production efficiency by diving deeper into throughput comparisons.

Source and External Links

Pick-and-Place Machine|Glossary - Nikon - A pick-and-place machine is automated equipment that places surface-mount components onto PCBs using a robotic arm with vacuum suction, crucial for high-speed electronics assembly like smartphones and laptops.

Pick-and-place machine - Wikipedia - Pick-and-place machines are robotic systems for precise, high-speed placement of surface-mount devices on PCBs, incorporating machine vision and AI for flexible, efficient manufacturing, and enabling IoT connectivity for predictive maintenance.

Top 10 SMT Machines Worldwide - NextPCB - Pick-and-place machines work by picking components and placing them on circuit boards using design files, and come in manual and automated types, with manual versions relying on operator skill but often being less accurate.

dowidth.com

dowidth.com