Flexible manufacturing systems enable efficient production by adapting to varied product types through automated processes and modular equipment, reducing downtime and increasing responsiveness. Additive manufacturing, also known as 3D printing, builds components layer by layer directly from digital models, allowing for complex geometries and customization with minimal material waste. Explore the key differences and applications of flexible and additive manufacturing to enhance your production strategy.

Why it is important

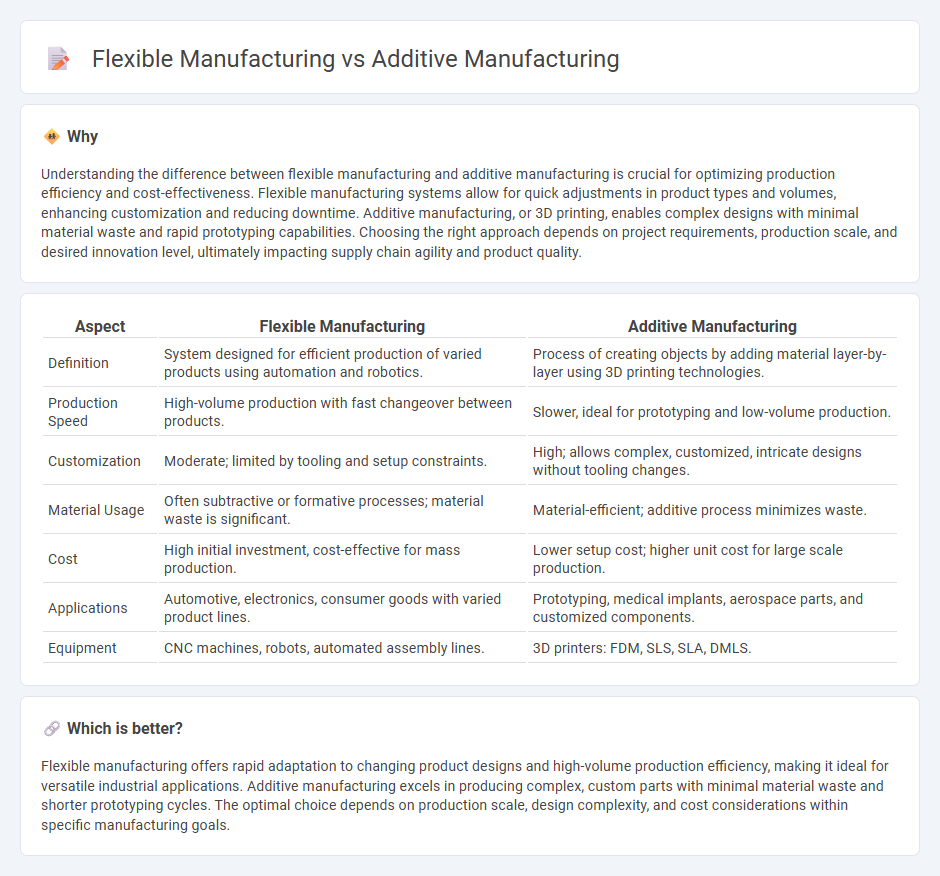

Understanding the difference between flexible manufacturing and additive manufacturing is crucial for optimizing production efficiency and cost-effectiveness. Flexible manufacturing systems allow for quick adjustments in product types and volumes, enhancing customization and reducing downtime. Additive manufacturing, or 3D printing, enables complex designs with minimal material waste and rapid prototyping capabilities. Choosing the right approach depends on project requirements, production scale, and desired innovation level, ultimately impacting supply chain agility and product quality.

Comparison Table

| Aspect | Flexible Manufacturing | Additive Manufacturing |

|---|---|---|

| Definition | System designed for efficient production of varied products using automation and robotics. | Process of creating objects by adding material layer-by-layer using 3D printing technologies. |

| Production Speed | High-volume production with fast changeover between products. | Slower, ideal for prototyping and low-volume production. |

| Customization | Moderate; limited by tooling and setup constraints. | High; allows complex, customized, intricate designs without tooling changes. |

| Material Usage | Often subtractive or formative processes; material waste is significant. | Material-efficient; additive process minimizes waste. |

| Cost | High initial investment, cost-effective for mass production. | Lower setup cost; higher unit cost for large scale production. |

| Applications | Automotive, electronics, consumer goods with varied product lines. | Prototyping, medical implants, aerospace parts, and customized components. |

| Equipment | CNC machines, robots, automated assembly lines. | 3D printers: FDM, SLS, SLA, DMLS. |

Which is better?

Flexible manufacturing offers rapid adaptation to changing product designs and high-volume production efficiency, making it ideal for versatile industrial applications. Additive manufacturing excels in producing complex, custom parts with minimal material waste and shorter prototyping cycles. The optimal choice depends on production scale, design complexity, and cost considerations within specific manufacturing goals.

Connection

Flexible manufacturing systems enhance production adaptability by integrating additive manufacturing techniques, enabling rapid prototyping and customized part fabrication without the need for dedicated tooling. Additive manufacturing supports flexible manufacturing by allowing on-demand production, reducing lead times, and minimizing inventory costs. The synergy between these technologies optimizes manufacturing processes, increases efficiency, and supports mass customization in modern industrial environments.

Key Terms

3D Printing

3D printing, a core technology in additive manufacturing, builds objects layer by layer using materials like plastics, metals, and composites, enabling complex geometries and rapid prototyping. Flexible manufacturing systems, in contrast, optimize production lines for adaptability and efficiency, integrating various processes to switch between different products with minimal downtime. Explore the unique advantages of 3D printing within flexible manufacturing frameworks to enhance innovation and production agility.

Reconfigurability

Additive manufacturing excels in reconfigurability by enabling rapid design changes and customization without the need for new tooling, making it ideal for prototyping and complex geometries. Flexible manufacturing systems offer reconfigurability through modular equipment and automated controls, allowing quick adaptation to different product types and volumes. Explore detailed comparisons of how reconfigurability impacts production efficiency and cost-effectiveness in both manufacturing approaches.

Customization

Additive manufacturing enables high levels of customization by producing complex, unique parts layer by layer directly from digital models, eliminating the need for specialized tooling. Flexible manufacturing systems achieve customization through adaptable machinery and reconfigurable processes capable of handling variable product types in small batches. Explore how each manufacturing approach enhances customization to determine the best fit for specific production goals.

Source and External Links

Additive manufacturing, explained | MIT Sloan - Additive manufacturing creates objects layer by layer directly from digital designs, commonly known as 3D printing, and has evolved from rapid prototyping to manufacturing functional parts using diverse materials like polymers, metals, and ceramics.

Additive manufacturing | NIST - Additive manufacturing builds three-dimensional products layer by layer using digital designs, enabling complex, material-efficient fabrication in fields ranging from aerospace to biomedical implants, with standards being developed to support industrial adoption.

The 7 categories of Additive Manufacturing - Loughborough University - Additive manufacturing encompasses multiple processes classified by ASTM into seven categories, including vat photopolymerization, material jetting, and binder jetting, each differing by materials and layering technology.

dowidth.com

dowidth.com