Machine vision enhances manufacturing accuracy and speed by using cameras and AI to inspect and guide assembly processes, reducing human error and increasing efficiency. Manual assembly relies on skilled workers for intricate tasks but often faces variability and slower production rates. Explore how integrating machine vision can revolutionize your assembly line performance and quality.

Why it is important

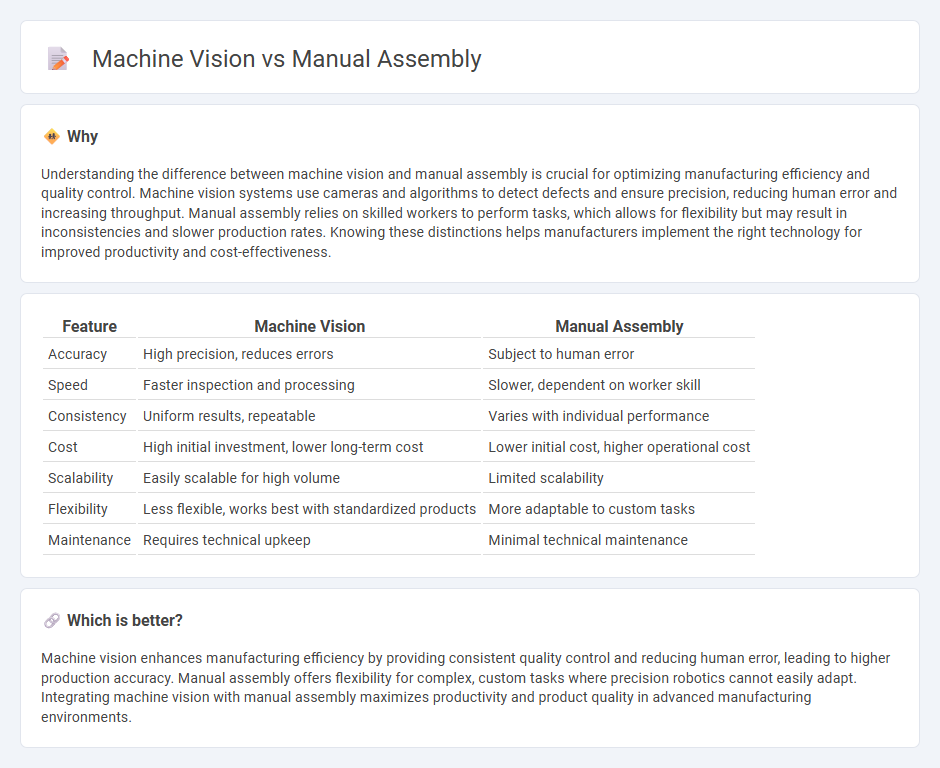

Understanding the difference between machine vision and manual assembly is crucial for optimizing manufacturing efficiency and quality control. Machine vision systems use cameras and algorithms to detect defects and ensure precision, reducing human error and increasing throughput. Manual assembly relies on skilled workers to perform tasks, which allows for flexibility but may result in inconsistencies and slower production rates. Knowing these distinctions helps manufacturers implement the right technology for improved productivity and cost-effectiveness.

Comparison Table

| Feature | Machine Vision | Manual Assembly |

|---|---|---|

| Accuracy | High precision, reduces errors | Subject to human error |

| Speed | Faster inspection and processing | Slower, dependent on worker skill |

| Consistency | Uniform results, repeatable | Varies with individual performance |

| Cost | High initial investment, lower long-term cost | Lower initial cost, higher operational cost |

| Scalability | Easily scalable for high volume | Limited scalability |

| Flexibility | Less flexible, works best with standardized products | More adaptable to custom tasks |

| Maintenance | Requires technical upkeep | Minimal technical maintenance |

Which is better?

Machine vision enhances manufacturing efficiency by providing consistent quality control and reducing human error, leading to higher production accuracy. Manual assembly offers flexibility for complex, custom tasks where precision robotics cannot easily adapt. Integrating machine vision with manual assembly maximizes productivity and product quality in advanced manufacturing environments.

Connection

Machine vision enhances manual assembly by providing real-time quality inspection, reducing human error, and increasing precision on production lines. Integrating automated visual inspection systems allows workers to detect defects faster and ensures components meet stringent manufacturing standards. This synergy boosts overall efficiency, product consistency, and reduces operational costs in manufacturing environments.

Key Terms

Human Labor

Human labor remains crucial in manual assembly, offering dexterity and adaptability in complex tasks where machines may struggle. Machine vision enhances efficiency by automating inspection and reducing human error, yet it often requires continuous human oversight for quality control. Discover more about how the integration of human expertise and machine vision optimizes production workflows.

Automation

Manual assembly relies heavily on human labor, which can introduce inconsistencies and slower production rates compared to the precision and speed offered by machine vision systems in automated manufacturing. Machine vision enhances quality control by accurately detecting defects, guiding robotic assembly, and ensuring high repeatability, significantly improving overall operational efficiency. Explore how integrating machine vision into automated lines can revolutionize your production process and reduce costs.

Defect Detection

Manual assembly relies heavily on human inspection for defect detection, which can lead to inconsistencies and higher error rates due to fatigue and subjective judgment. Machine vision systems utilize advanced cameras and AI algorithms to identify defects with high precision and speed, ensuring consistent quality control in manufacturing processes. Explore how integrating machine vision can enhance defect detection efficiency in your production line.

Source and External Links

Manual vs. Automated Assembly - Manual PCB assembly is faster and more economical for low-volume or prototype runs, especially with through-hole components, but may require skilled technicians for quality inspection and rework.

Manual vs. Automated Assembly: Choose the Right Type of PCB Assembly - Manual assembly offers flexibility and cost savings for small batches or prototypes, but is slower, labor-intensive, and prone to human error compared to automated methods.

Manual assembly - Manual assembly relies on human dexterity and intelligence, often supported by tools and guidance systems to maintain quality and efficiency in manufacturing processes.

dowidth.com

dowidth.com