Collaborative robots, or cobots, enhance manufacturing efficiency by working alongside human operators, offering flexibility and precision that traditional assembly lines often lack. Unlike traditional assembly lines, which rely on repetitive, segmented tasks with limited adaptability, cobots can be easily programmed for diverse functions and ensure higher safety standards through advanced sensors and AI integration. Discover the transformative impact of collaborative robots on modern manufacturing processes.

Why it is important

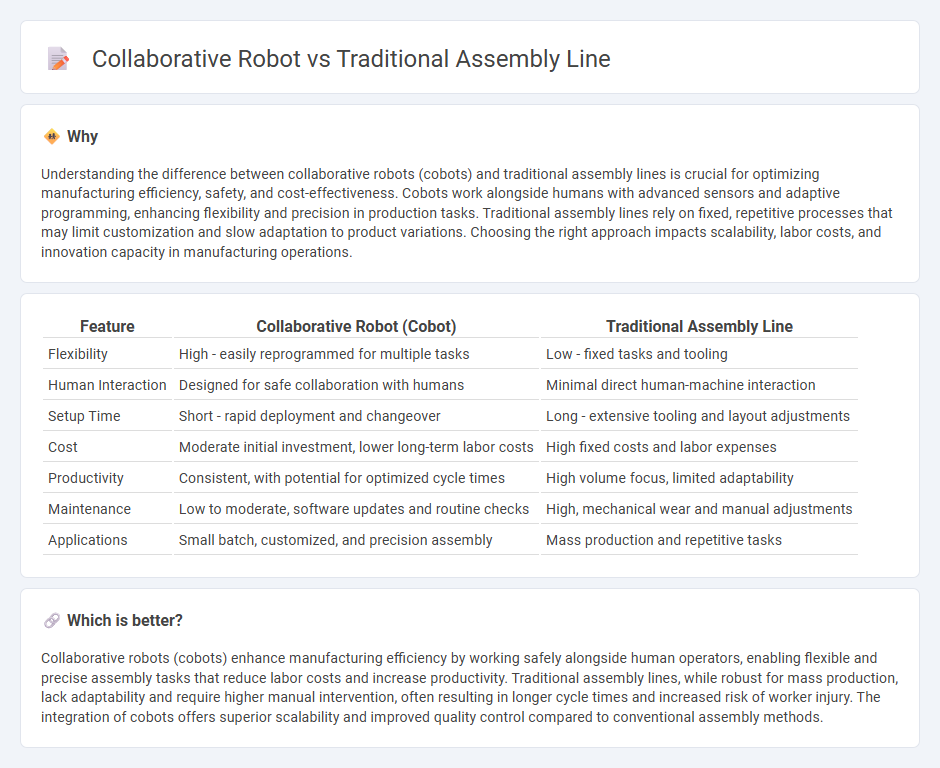

Understanding the difference between collaborative robots (cobots) and traditional assembly lines is crucial for optimizing manufacturing efficiency, safety, and cost-effectiveness. Cobots work alongside humans with advanced sensors and adaptive programming, enhancing flexibility and precision in production tasks. Traditional assembly lines rely on fixed, repetitive processes that may limit customization and slow adaptation to product variations. Choosing the right approach impacts scalability, labor costs, and innovation capacity in manufacturing operations.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Traditional Assembly Line |

|---|---|---|

| Flexibility | High - easily reprogrammed for multiple tasks | Low - fixed tasks and tooling |

| Human Interaction | Designed for safe collaboration with humans | Minimal direct human-machine interaction |

| Setup Time | Short - rapid deployment and changeover | Long - extensive tooling and layout adjustments |

| Cost | Moderate initial investment, lower long-term labor costs | High fixed costs and labor expenses |

| Productivity | Consistent, with potential for optimized cycle times | High volume focus, limited adaptability |

| Maintenance | Low to moderate, software updates and routine checks | High, mechanical wear and manual adjustments |

| Applications | Small batch, customized, and precision assembly | Mass production and repetitive tasks |

Which is better?

Collaborative robots (cobots) enhance manufacturing efficiency by working safely alongside human operators, enabling flexible and precise assembly tasks that reduce labor costs and increase productivity. Traditional assembly lines, while robust for mass production, lack adaptability and require higher manual intervention, often resulting in longer cycle times and increased risk of worker injury. The integration of cobots offers superior scalability and improved quality control compared to conventional assembly methods.

Connection

Collaborative robots (cobots) integrate seamlessly into traditional assembly lines by enhancing efficiency and flexibility without replacing human workers. Cobots handle repetitive, precise tasks alongside operators, reducing errors and improving throughput in manufacturing processes. This synergy accelerates production cycles while maintaining high-quality standards on conventional assembly lines.

Key Terms

Fixed Automation

Traditional assembly lines rely on fixed automation systems characterized by rigid, pre-programmed machinery designed for repetitive tasks with minimal flexibility, often resulting in high initial investment and limited adaptability. Collaborative robots (cobots) enhance fixed automation by offering programmable, user-friendly interfaces and safety features that allow seamless human-robot interaction, boosting productivity and reducing downtime. Discover how integrating cobots into fixed automation transforms manufacturing efficiency and scalability.

Human-Robot Interaction

Traditional assembly lines rely heavily on human labor performing repetitive tasks, often leading to fatigue and errors, whereas collaborative robots (cobots) are designed to work safely alongside humans, enhancing productivity and reducing physical strain. Cobots integrate advanced sensors and machine learning algorithms to adapt to human movements, enabling seamless interaction and real-time task adjustments. Discover how human-robot collaboration is transforming manufacturing efficiency and workplace safety by exploring the latest innovations in cobot technology.

Flexibility

Traditional assembly lines offer limited flexibility with fixed stations designed for repetitive tasks, leading to higher setup times and reduced adaptability to product changes. Collaborative robots (cobots) enhance flexibility by easily reprogramming and integrating with existing workflows, allowing real-time adjustments and customization in production processes. Explore how cobots transform manufacturing agility to boost efficiency and reduce downtime.

Source and External Links

Assembly Line: Manufacturing Explained - The classic assembly line involves workers or machines arranged in a straight line, each performing a specific task in sequence, ideal for mass production of standardized products with efficiency and simplicity but limited flexibility.

The Different Types of Assembly Lines in Manufacturing - The classic assembly line, epitomized by early car manufacturing, uses multiple sequential steps performed by different workers to produce essentially identical, complex products like cars.

Assembly line (manufacturing) - Traditional assembly lines are systematic sequences where workers or machines at stations modify products moving along a conveyor belt, pioneered by Henry Ford to reduce production time and costs significantly in the early 1900s.

dowidth.com

dowidth.com