Condition-based monitoring uses real-time data from sensors to assess equipment performance and trigger maintenance only when certain thresholds are exceeded. Predictive maintenance employs advanced analytics and machine learning algorithms to forecast potential failures before they occur, optimizing maintenance schedules and reducing downtime. Explore how these innovative approaches enhance manufacturing efficiency and asset management.

Why it is important

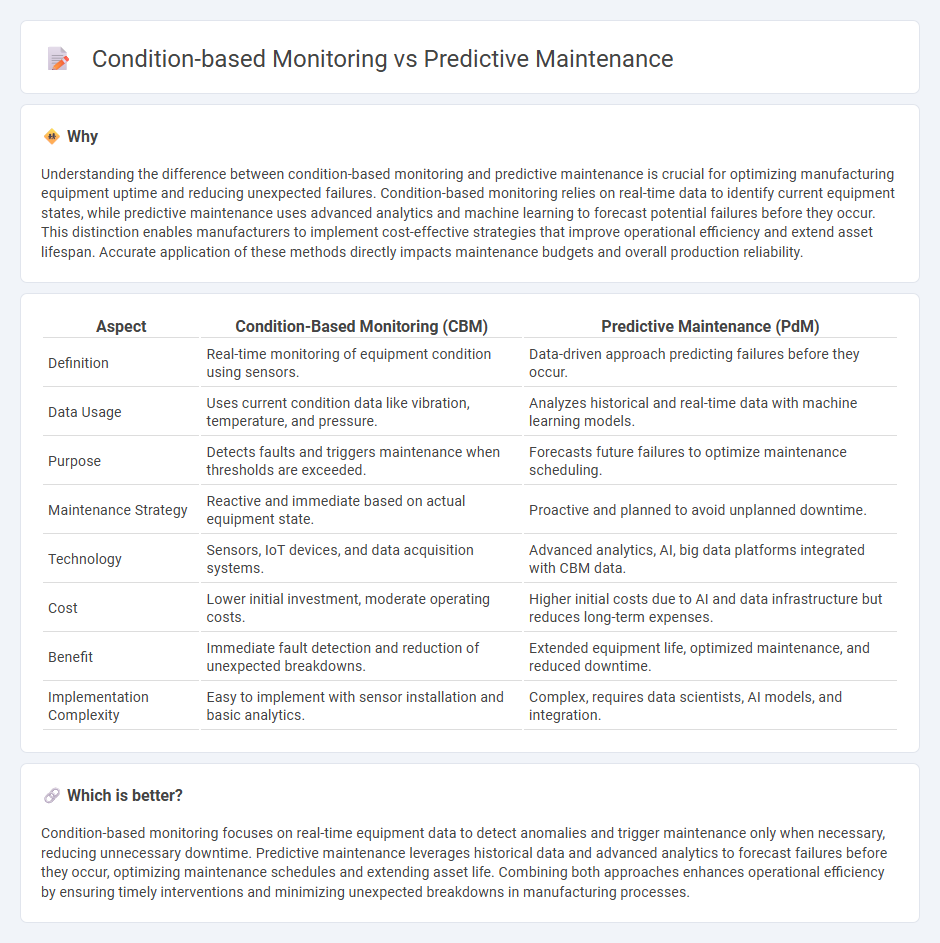

Understanding the difference between condition-based monitoring and predictive maintenance is crucial for optimizing manufacturing equipment uptime and reducing unexpected failures. Condition-based monitoring relies on real-time data to identify current equipment states, while predictive maintenance uses advanced analytics and machine learning to forecast potential failures before they occur. This distinction enables manufacturers to implement cost-effective strategies that improve operational efficiency and extend asset lifespan. Accurate application of these methods directly impacts maintenance budgets and overall production reliability.

Comparison Table

| Aspect | Condition-Based Monitoring (CBM) | Predictive Maintenance (PdM) |

|---|---|---|

| Definition | Real-time monitoring of equipment condition using sensors. | Data-driven approach predicting failures before they occur. |

| Data Usage | Uses current condition data like vibration, temperature, and pressure. | Analyzes historical and real-time data with machine learning models. |

| Purpose | Detects faults and triggers maintenance when thresholds are exceeded. | Forecasts future failures to optimize maintenance scheduling. |

| Maintenance Strategy | Reactive and immediate based on actual equipment state. | Proactive and planned to avoid unplanned downtime. |

| Technology | Sensors, IoT devices, and data acquisition systems. | Advanced analytics, AI, big data platforms integrated with CBM data. |

| Cost | Lower initial investment, moderate operating costs. | Higher initial costs due to AI and data infrastructure but reduces long-term expenses. |

| Benefit | Immediate fault detection and reduction of unexpected breakdowns. | Extended equipment life, optimized maintenance, and reduced downtime. |

| Implementation Complexity | Easy to implement with sensor installation and basic analytics. | Complex, requires data scientists, AI models, and integration. |

Which is better?

Condition-based monitoring focuses on real-time equipment data to detect anomalies and trigger maintenance only when necessary, reducing unnecessary downtime. Predictive maintenance leverages historical data and advanced analytics to forecast failures before they occur, optimizing maintenance schedules and extending asset life. Combining both approaches enhances operational efficiency by ensuring timely interventions and minimizing unexpected breakdowns in manufacturing processes.

Connection

Condition-based monitoring collects real-time data on equipment performance, enabling early detection of potential failures through sensor measurements and analysis of vibration, temperature, and pressure. Predictive maintenance uses this data to forecast machinery breakdowns, optimizing maintenance schedules and reducing downtime by anticipating issues before they cause disruptions. Together, these technologies improve asset reliability, extend equipment lifespan, and lower operational costs in manufacturing environments.

Key Terms

Sensors

Predictive maintenance leverages advanced sensors to collect continuous data on equipment performance, enabling algorithms to forecast potential failures before they occur. Condition-based monitoring uses sensors to track real-time parameters such as temperature, vibration, and pressure, triggering maintenance only when thresholds are exceeded. Explore key sensor technologies and their impact on optimizing maintenance strategies for improved operational efficiency.

Failure Prediction

Predictive maintenance leverages advanced analytics and machine learning algorithms to forecast equipment failures before they occur, optimizing repair schedules and minimizing downtime. Condition-based monitoring relies on real-time data from sensors to assess the current state of machinery and trigger maintenance only when specific indicators show degradation. Explore in-depth strategies and technologies to enhance failure prediction accuracy in industrial applications.

Real-time Data

Predictive maintenance leverages real-time data analytics and machine learning algorithms to forecast equipment failures before they occur, minimizing downtime and repair costs. Condition-based monitoring continuously collects sensor data such as temperature, vibration, and pressure to assess equipment health and trigger maintenance only when specific thresholds are exceeded. Discover how integrating these advanced data-driven strategies can revolutionize your maintenance operations and drive operational excellence.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses sensor data and machine learning to continuously assess equipment health, predict future failures, and enable maintenance only when necessary, thus reducing downtime and costs while optimizing reliability and lifespan.

Predictive maintenance - Wikipedia - Predictive maintenance estimates equipment condition to schedule maintenance based on actual data and machine learning, reducing unexpected failures and optimizing plant availability and safety compared to routine or preventive maintenance.

What is Predictive Maintenance? Benefits, Challenges & Examples - Predictive maintenance analyzes real-time vehicle and sensor data to forecast failures in advance, improving fleet uptime, reducing maintenance costs, prioritizing urgent tasks, optimizing inventory, and extending asset life.

dowidth.com

dowidth.com