Human augmentation enhances worker capabilities through wearable devices and neural interfaces, improving precision, strength, and real-time decision-making in manufacturing processes. Machine vision leverages advanced cameras and AI algorithms to automate quality control and detect defects with unparalleled speed and accuracy. Discover how integrating human augmentation and machine vision is transforming manufacturing efficiency and innovation.

Why it is important

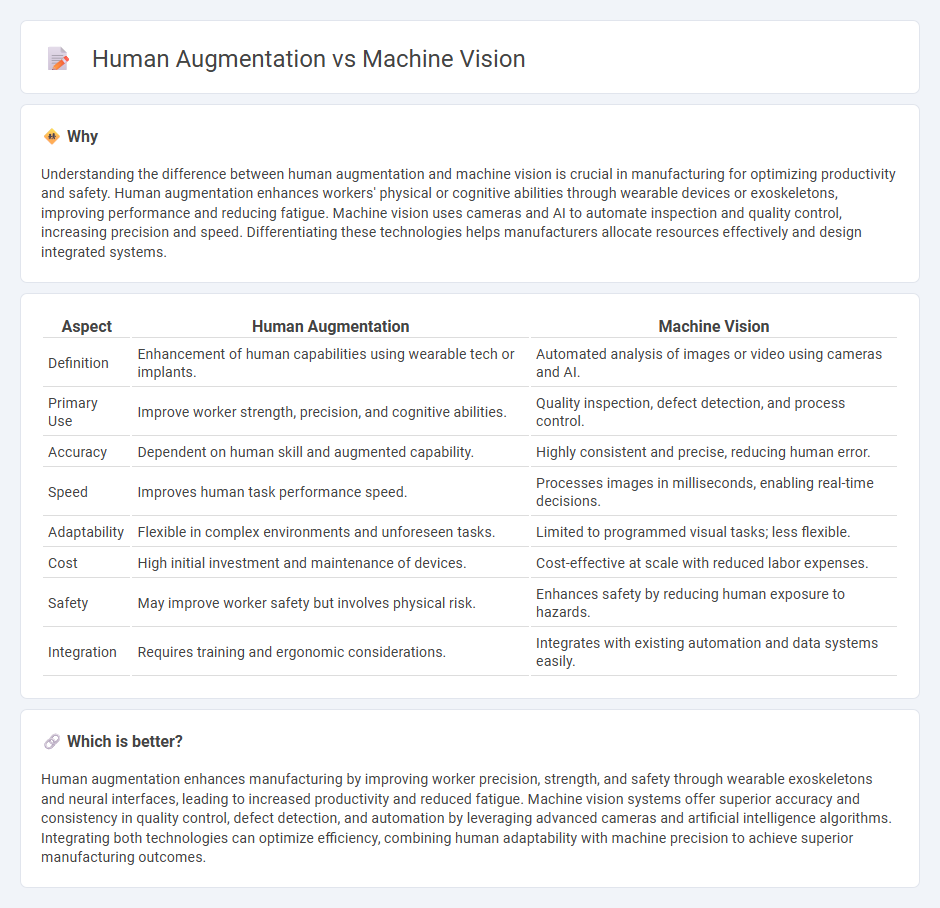

Understanding the difference between human augmentation and machine vision is crucial in manufacturing for optimizing productivity and safety. Human augmentation enhances workers' physical or cognitive abilities through wearable devices or exoskeletons, improving performance and reducing fatigue. Machine vision uses cameras and AI to automate inspection and quality control, increasing precision and speed. Differentiating these technologies helps manufacturers allocate resources effectively and design integrated systems.

Comparison Table

| Aspect | Human Augmentation | Machine Vision |

|---|---|---|

| Definition | Enhancement of human capabilities using wearable tech or implants. | Automated analysis of images or video using cameras and AI. |

| Primary Use | Improve worker strength, precision, and cognitive abilities. | Quality inspection, defect detection, and process control. |

| Accuracy | Dependent on human skill and augmented capability. | Highly consistent and precise, reducing human error. |

| Speed | Improves human task performance speed. | Processes images in milliseconds, enabling real-time decisions. |

| Adaptability | Flexible in complex environments and unforeseen tasks. | Limited to programmed visual tasks; less flexible. |

| Cost | High initial investment and maintenance of devices. | Cost-effective at scale with reduced labor expenses. |

| Safety | May improve worker safety but involves physical risk. | Enhances safety by reducing human exposure to hazards. |

| Integration | Requires training and ergonomic considerations. | Integrates with existing automation and data systems easily. |

Which is better?

Human augmentation enhances manufacturing by improving worker precision, strength, and safety through wearable exoskeletons and neural interfaces, leading to increased productivity and reduced fatigue. Machine vision systems offer superior accuracy and consistency in quality control, defect detection, and automation by leveraging advanced cameras and artificial intelligence algorithms. Integrating both technologies can optimize efficiency, combining human adaptability with machine precision to achieve superior manufacturing outcomes.

Connection

Human augmentation enhances workers' capabilities by integrating wearable sensors and exoskeletons that improve strength and precision, while machine vision systems provide real-time quality inspection and process monitoring. The synergy between human augmentation and machine vision enables seamless collaboration, optimizing assembly line efficiency and reducing error rates through enhanced sensory feedback and automated visual analysis. Combining these technologies supports predictive maintenance and adaptive manufacturing, driving innovation and competitive advantage in the manufacturing industry.

Key Terms

**Machine Vision:**

Machine vision employs advanced algorithms and high-resolution cameras to analyze visual data rapidly and with high accuracy, outperforming human capabilities in repetitive or complex inspection tasks. Industries such as manufacturing, healthcare, and autonomous vehicles leverage machine vision for defect detection, quality control, and real-time decision-making, significantly increasing productivity and reducing error rates. Explore deeper insights into machine vision technology and its impact on modern automation solutions.

Image Processing

Machine vision leverages advanced algorithms and high-resolution cameras to rapidly analyze and interpret images with precision far surpassing human capabilities. Human augmentation in image processing enhances visual perception through wearable technology, enabling real-time data overlay and improved decision-making in complex environments. Discover how these cutting-edge technologies revolutionize image processing by exploring their unique applications and benefits.

Automated Inspection

Automated inspection leverages machine vision technology to enhance accuracy and speed beyond human capabilities, identifying defects with high precision in manufacturing and quality control processes. Human augmentation integrates machine vision systems with wearable devices or augmented reality to empower workers with real-time data and decision support during inspections. Explore how the synergy between machine vision and human augmentation transforms automated inspection efficiency and reliability.

Source and External Links

What Is Machine Vision? (Intel) - Machine vision combines smart cameras, industrial PCs, and AI to automate quality inspection, part identification, and robotic guidance in manufacturing, enabling high-speed, accurate decision-making on the factory floor.

Machine Vision Vs Computer Vision (Zebra Technologies) - Machine vision is a specialized subset of computer vision focused on industrial applications, using image capture and analysis to drive actions like object inspection, flaw detection, and process control in structured environments.

Machine vision basics: definitions, uses, and benefits (Cognex) - Machine vision allows automated systems to visually identify, measure, and sort components or products with high speed and accuracy, improving quality, reducing waste, and enabling efficient tracking in logistics and manufacturing.

dowidth.com

dowidth.com