Industrial metaverse integrates virtual reality, augmented reality, and digital twins to create immersive environments that enhance manufacturing processes. Industrial IoT focuses on connecting machines and sensors through the internet to enable real-time data collection and analytics for optimizing production efficiency. Discover how these technologies revolutionize manufacturing by exploring their unique benefits and applications.

Why it is important

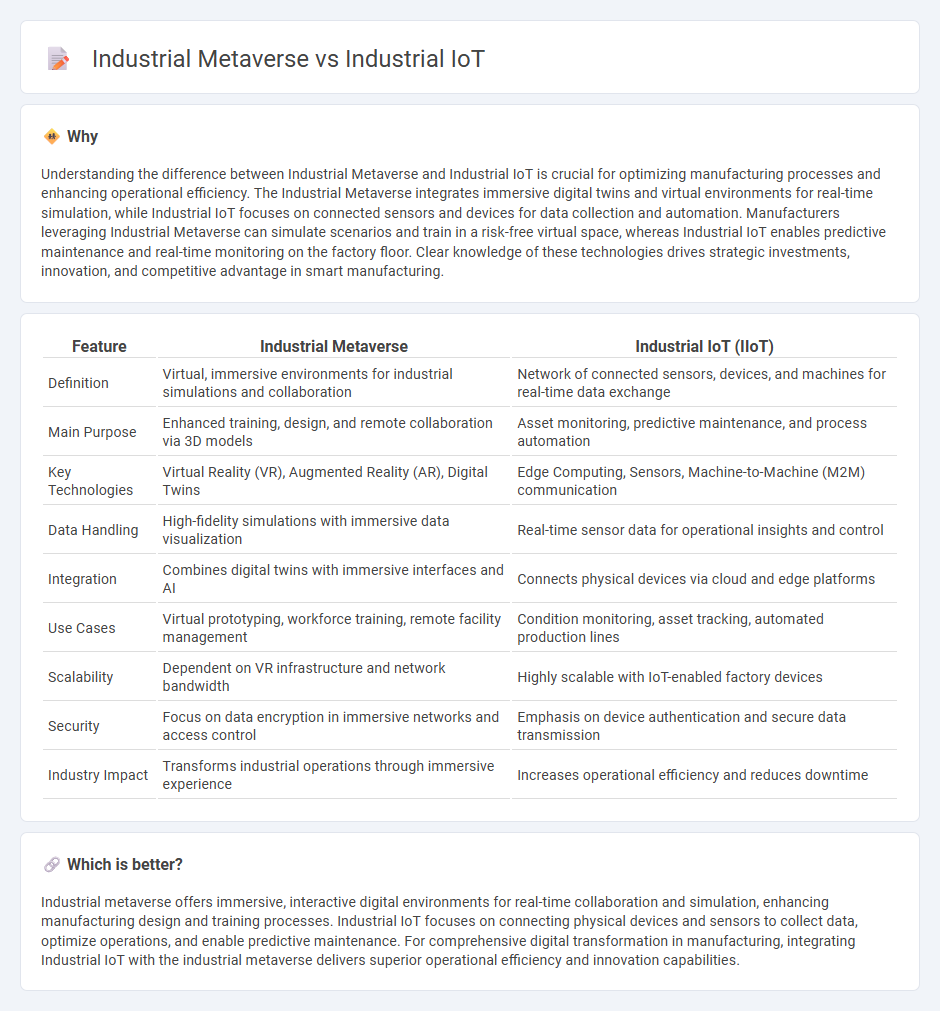

Understanding the difference between Industrial Metaverse and Industrial IoT is crucial for optimizing manufacturing processes and enhancing operational efficiency. The Industrial Metaverse integrates immersive digital twins and virtual environments for real-time simulation, while Industrial IoT focuses on connected sensors and devices for data collection and automation. Manufacturers leveraging Industrial Metaverse can simulate scenarios and train in a risk-free virtual space, whereas Industrial IoT enables predictive maintenance and real-time monitoring on the factory floor. Clear knowledge of these technologies drives strategic investments, innovation, and competitive advantage in smart manufacturing.

Comparison Table

| Feature | Industrial Metaverse | Industrial IoT (IIoT) |

|---|---|---|

| Definition | Virtual, immersive environments for industrial simulations and collaboration | Network of connected sensors, devices, and machines for real-time data exchange |

| Main Purpose | Enhanced training, design, and remote collaboration via 3D models | Asset monitoring, predictive maintenance, and process automation |

| Key Technologies | Virtual Reality (VR), Augmented Reality (AR), Digital Twins | Edge Computing, Sensors, Machine-to-Machine (M2M) communication |

| Data Handling | High-fidelity simulations with immersive data visualization | Real-time sensor data for operational insights and control |

| Integration | Combines digital twins with immersive interfaces and AI | Connects physical devices via cloud and edge platforms |

| Use Cases | Virtual prototyping, workforce training, remote facility management | Condition monitoring, asset tracking, automated production lines |

| Scalability | Dependent on VR infrastructure and network bandwidth | Highly scalable with IoT-enabled factory devices |

| Security | Focus on data encryption in immersive networks and access control | Emphasis on device authentication and secure data transmission |

| Industry Impact | Transforms industrial operations through immersive experience | Increases operational efficiency and reduces downtime |

Which is better?

Industrial metaverse offers immersive, interactive digital environments for real-time collaboration and simulation, enhancing manufacturing design and training processes. Industrial IoT focuses on connecting physical devices and sensors to collect data, optimize operations, and enable predictive maintenance. For comprehensive digital transformation in manufacturing, integrating Industrial IoT with the industrial metaverse delivers superior operational efficiency and innovation capabilities.

Connection

The Industrial Metaverse leverages Industrial IoT (IIoT) by integrating real-time sensor data from connected machinery to create immersive digital twins that mirror physical manufacturing environments. This synergy enables enhanced predictive maintenance, optimized production workflows, and remote monitoring within virtual simulations. By combining IIoT data streams with advanced visualization technologies, manufacturers achieve greater operational efficiency and accelerated innovation cycles.

Key Terms

Connectivity

Industrial IoT (IIoT) leverages sensor networks, machine-to-machine (M2M) communication, and cloud integration to enable real-time data exchange and predictive maintenance across manufacturing systems. The industrial metaverse incorporates IIoT connectivity but extends it by integrating augmented reality (AR), digital twins, and immersive virtual environments to enhance collaboration and operational visualization. Explore how these technologies revolutionize industrial connectivity and drive smarter, more connected manufacturing processes.

Digital Twin

Industrial IoT integrates sensors and real-time data analytics to create Digital Twins that mirror physical assets for monitoring and predictive maintenance. The Industrial Metaverse expands this concept by embedding these Digital Twins into a persistent, virtual environment enabling immersive simulations, collaboration, and advanced scenario planning. Discover how the fusion of Industrial IoT and the Industrial Metaverse transforms Digital Twin applications into comprehensive digital ecosystems.

Immersive Simulation

Industrial IoT leverages interconnected sensors and devices to collect real-time data for monitoring and optimizing manufacturing processes. Industrial metaverse builds on this foundation by integrating immersive simulation technologies such as virtual and augmented reality to create interactive, 3D digital twins for scenario planning and training. Explore how immersive simulation transforms industrial operations by blending IoT data with virtual environments.

Source and External Links

Industrial IoT | Digital Transformation - AWS - Industrial IoT (IIoT) integrates machines, cloud, analytics, and people to digitize processes, boost productivity, and enable predictive quality and maintenance across industries like manufacturing, energy, and agriculture.

What is industrial IoT - Arm - IIoT enables real-time monitoring, control, and optimization of industrial processes and supply chains by connecting smart, low-power devices operating from sensor to cloud.

What is IIoT (Industrial Internet of Things)? | Definition from TechTarget - IIoT uses networked smart sensors and actuators to collect, exchange, and analyze data, improving efficiency, reliability, and enabling predictive maintenance in manufacturing and energy sectors.

dowidth.com

dowidth.com