Predictive maintenance utilizes data analytics and IoT sensors to anticipate equipment failures before they occur, reducing downtime and maintenance costs. Run-to-failure maintenance involves operating machinery until breakdown, which often leads to unexpected production halts and higher repair expenses. Discover how choosing the right strategy can optimize your manufacturing efficiency and asset longevity.

Why it is important

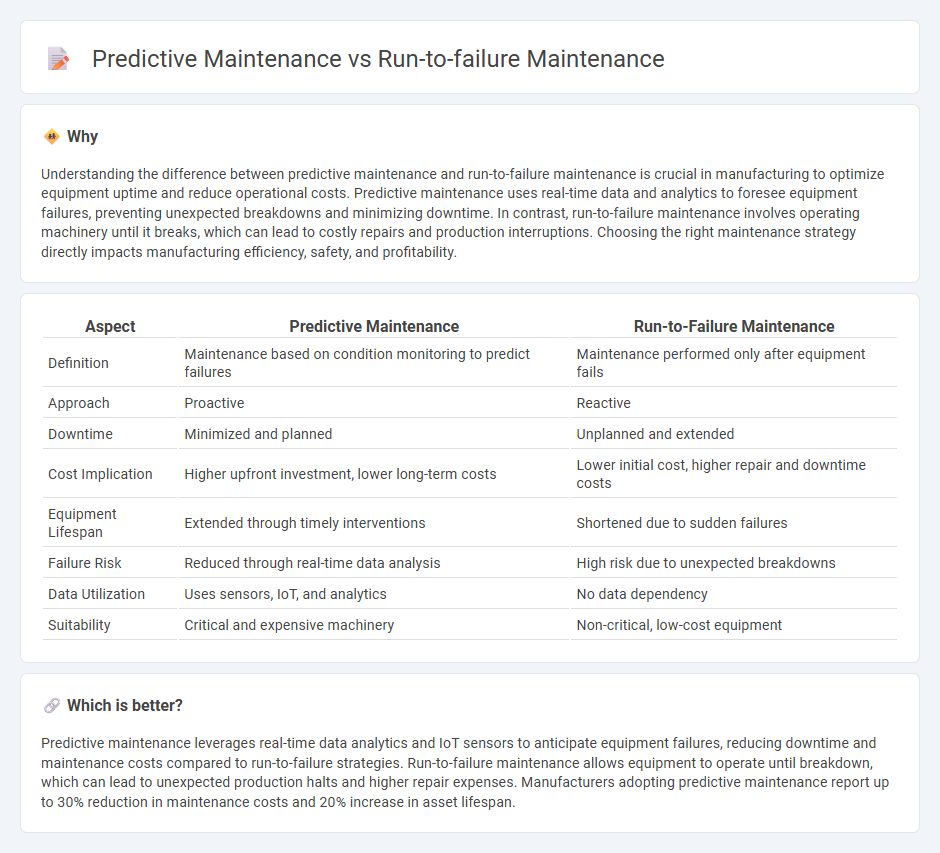

Understanding the difference between predictive maintenance and run-to-failure maintenance is crucial in manufacturing to optimize equipment uptime and reduce operational costs. Predictive maintenance uses real-time data and analytics to foresee equipment failures, preventing unexpected breakdowns and minimizing downtime. In contrast, run-to-failure maintenance involves operating machinery until it breaks, which can lead to costly repairs and production interruptions. Choosing the right maintenance strategy directly impacts manufacturing efficiency, safety, and profitability.

Comparison Table

| Aspect | Predictive Maintenance | Run-to-Failure Maintenance |

|---|---|---|

| Definition | Maintenance based on condition monitoring to predict failures | Maintenance performed only after equipment fails |

| Approach | Proactive | Reactive |

| Downtime | Minimized and planned | Unplanned and extended |

| Cost Implication | Higher upfront investment, lower long-term costs | Lower initial cost, higher repair and downtime costs |

| Equipment Lifespan | Extended through timely interventions | Shortened due to sudden failures |

| Failure Risk | Reduced through real-time data analysis | High risk due to unexpected breakdowns |

| Data Utilization | Uses sensors, IoT, and analytics | No data dependency |

| Suitability | Critical and expensive machinery | Non-critical, low-cost equipment |

Which is better?

Predictive maintenance leverages real-time data analytics and IoT sensors to anticipate equipment failures, reducing downtime and maintenance costs compared to run-to-failure strategies. Run-to-failure maintenance allows equipment to operate until breakdown, which can lead to unexpected production halts and higher repair expenses. Manufacturers adopting predictive maintenance report up to 30% reduction in maintenance costs and 20% increase in asset lifespan.

Connection

Predictive maintenance and run-to-failure maintenance are connected through their focus on equipment lifecycle management but differ in approach; predictive maintenance uses data analytics and IoT sensors to forecast failures and schedule timely interventions, minimizing downtime and repair costs. Run-to-failure maintenance allows equipment to operate until breakdown, which can be strategically applied when the cost of downtime or repair is lower than preventive actions. Integrating predictive maintenance data can optimize run-to-failure decisions by identifying critical components that benefit most from condition-based monitoring.

Key Terms

Downtime

Run-to-failure maintenance leads to unpredictable and often prolonged downtime due to unexpected equipment breakdowns, causing significant disruptions in production. Predictive maintenance utilizes real-time data and condition monitoring to forecast failures, effectively minimizing downtime by scheduling maintenance only when needed. Explore how predictive maintenance can enhance operational efficiency and reduce downtime costs in your industry.

Condition Monitoring

Run-to-failure maintenance allows equipment to operate until breakdown occurs, leading to unplanned downtime and higher repair costs, whereas predictive maintenance uses condition monitoring technologies like vibration analysis, thermography, and oil analysis to anticipate failures and schedule repairs proactively. Condition monitoring provides real-time data that enhance asset reliability, optimize maintenance schedules, and reduce operational expenses by targeting interventions only when necessary. Explore the latest advancements in condition monitoring to maximize your maintenance strategy efficiency.

Failure Prediction

Run-to-failure maintenance allows equipment to operate until it breaks down, often leading to unexpected downtime and costly repairs, while predictive maintenance uses data analytics and sensor technologies to forecast potential failures before they occur. Failure prediction models leverage machine learning algorithms, vibration analysis, and thermal imaging to optimize maintenance schedules, reduce operational costs, and enhance equipment reliability. Discover how integrating advanced failure prediction techniques can transform your maintenance strategy and maximize asset performance.

Source and External Links

What is the Difference between Run-to-Failure and Breakdown Maintenance? - Run-to-failure maintenance is a simple strategy where assets are allowed to operate until failure occurs, and then maintenance is performed; it's planned and mainly applied to non-critical equipment to save costs.

When to implement run-to-failure (RTF) maintenance - Eptura - Run-to-failure means letting a specific part run until it fails without inspections or active maintenance, and then replacing it instead of repairing.

Optimizing Your Strategy with Run-to-Failure Maintenance - MicroMain - RTF is a reactive maintenance approach where equipment is used until it fails, then fixed or replaced, ideal for non-critical and low-value items, offering cost savings due to no scheduled upkeep.

dowidth.com

dowidth.com