Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing processes and boost operational efficiency. Total Quality Management (TQM) focuses on continuous improvement, employee involvement, and customer satisfaction to enhance product quality and reduce defects. Explore how integrating hyperautomation with TQM strategies can transform manufacturing performance.

Why it is important

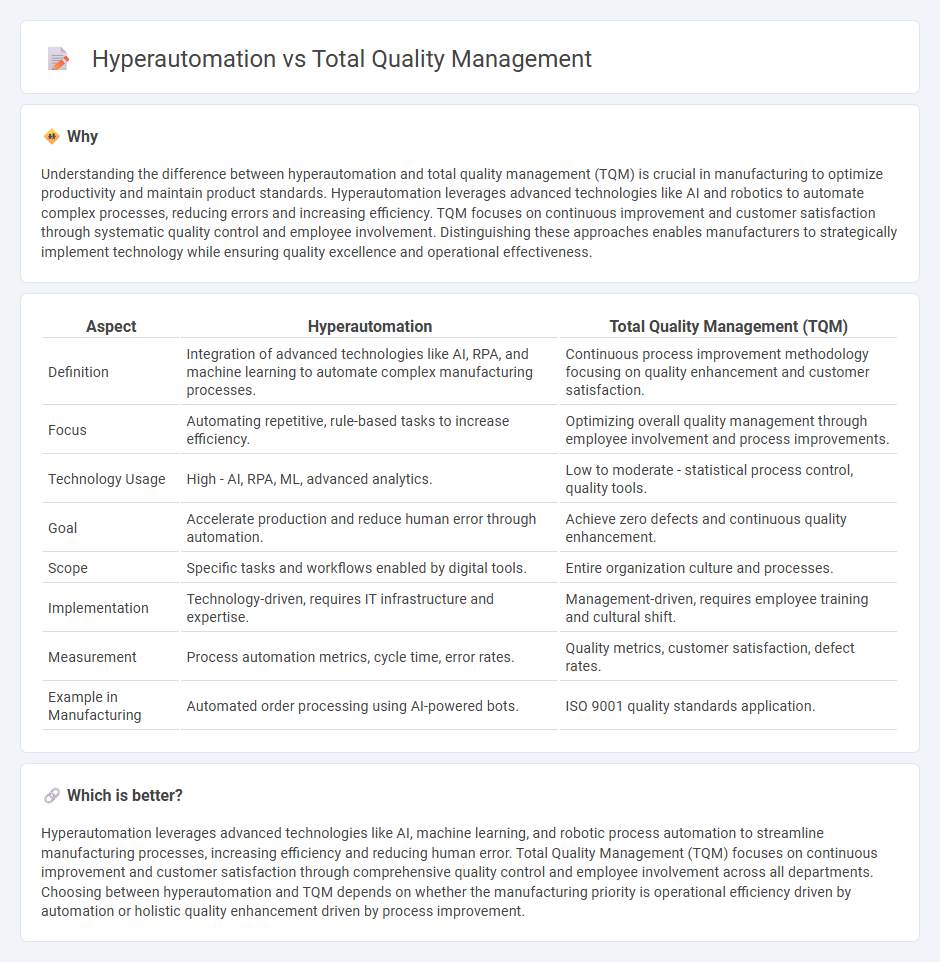

Understanding the difference between hyperautomation and total quality management (TQM) is crucial in manufacturing to optimize productivity and maintain product standards. Hyperautomation leverages advanced technologies like AI and robotics to automate complex processes, reducing errors and increasing efficiency. TQM focuses on continuous improvement and customer satisfaction through systematic quality control and employee involvement. Distinguishing these approaches enables manufacturers to strategically implement technology while ensuring quality excellence and operational effectiveness.

Comparison Table

| Aspect | Hyperautomation | Total Quality Management (TQM) |

|---|---|---|

| Definition | Integration of advanced technologies like AI, RPA, and machine learning to automate complex manufacturing processes. | Continuous process improvement methodology focusing on quality enhancement and customer satisfaction. |

| Focus | Automating repetitive, rule-based tasks to increase efficiency. | Optimizing overall quality management through employee involvement and process improvements. |

| Technology Usage | High - AI, RPA, ML, advanced analytics. | Low to moderate - statistical process control, quality tools. |

| Goal | Accelerate production and reduce human error through automation. | Achieve zero defects and continuous quality enhancement. |

| Scope | Specific tasks and workflows enabled by digital tools. | Entire organization culture and processes. |

| Implementation | Technology-driven, requires IT infrastructure and expertise. | Management-driven, requires employee training and cultural shift. |

| Measurement | Process automation metrics, cycle time, error rates. | Quality metrics, customer satisfaction, defect rates. |

| Example in Manufacturing | Automated order processing using AI-powered bots. | ISO 9001 quality standards application. |

Which is better?

Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing processes, increasing efficiency and reducing human error. Total Quality Management (TQM) focuses on continuous improvement and customer satisfaction through comprehensive quality control and employee involvement across all departments. Choosing between hyperautomation and TQM depends on whether the manufacturing priority is operational efficiency driven by automation or holistic quality enhancement driven by process improvement.

Connection

Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing processes, which directly enhances the implementation of Total Quality Management (TQM) by enabling real-time data analysis and continuous improvement. Total Quality Management benefits from hyperautomation through improved process consistency, reduction of human errors, and accelerated feedback loops that promote product quality and operational efficiency. The synergy between hyperautomation and TQM drives manufacturing excellence by aligning automated workflows with quality objectives, thus boosting overall productivity and customer satisfaction.

Key Terms

**Total Quality Management:**

Total Quality Management (TQM) centers on continuous improvement, customer satisfaction, and employee involvement to enhance organizational processes and product quality. It emphasizes data-driven decision-making, process standardization, and comprehensive training to reduce errors and inefficiencies. Explore more to understand how TQM principles can transform business operations and compete with hyperautomation strategies.

Continuous Improvement

Total Quality Management (TQM) emphasizes continuous improvement through systematic feedback, employee involvement, and process optimization to enhance product quality and customer satisfaction. Hyperautomation leverages advanced technologies such as AI, machine learning, and robotic process automation to accelerate and scale continuous improvement by automating complex workflows and data analysis. Explore how integrating TQM principles with hyperautomation strategies can drive superior operational excellence and sustained growth.

Customer Focus

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction through systematic processes and employee involvement, ensuring consistent product and service quality. Hyperautomation leverages advanced technologies like AI and RPA to streamline workflows and enhance responsiveness, directly improving customer experience by reducing errors and speeding delivery. Explore how integrating TQM with hyperautomation can drive superior customer focus and operational excellence.

Source and External Links

Total Quality Management (TQM): What Is It, Principles and Systems - This article provides an overview of Total Quality Management, outlining its principles and steps for implementation, including the PDCA cycle.

Total Quality Management (TQM) PDF - This document defines TQM as a philosophy emphasizing continuous improvement across all organizational operations, focusing on customer satisfaction and employee involvement.

Mastering the 8 Principles of TQM - This article highlights the core principles of TQM, including client-centricity, leadership, and continuous refinement, and discusses its benefits in optimizing operations and client satisfaction.

dowidth.com

dowidth.com