Circular manufacturing emphasizes resource efficiency by reusing materials and minimizing waste throughout the production cycle, promoting sustainability and environmental responsibility. Discrete manufacturing focuses on producing distinct, countable products through assembly lines, often involving complex configurations and customization. Explore how each manufacturing approach can optimize operations and support your business goals.

Why it is important

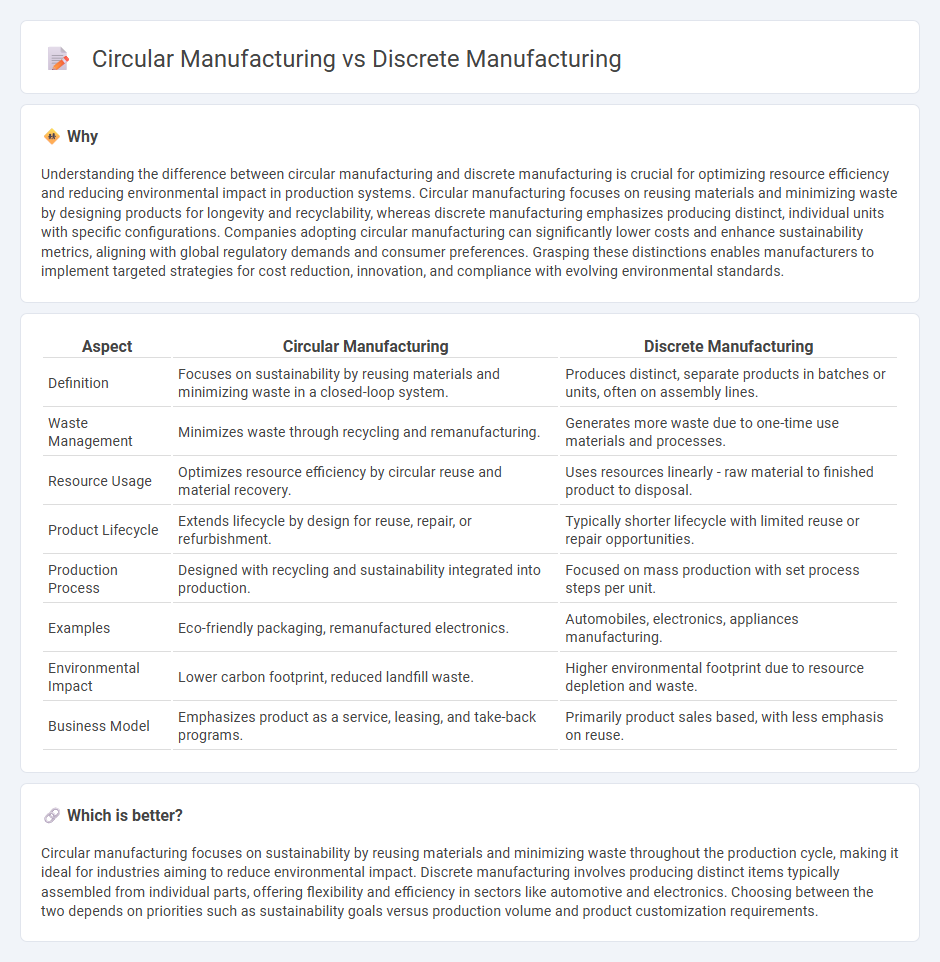

Understanding the difference between circular manufacturing and discrete manufacturing is crucial for optimizing resource efficiency and reducing environmental impact in production systems. Circular manufacturing focuses on reusing materials and minimizing waste by designing products for longevity and recyclability, whereas discrete manufacturing emphasizes producing distinct, individual units with specific configurations. Companies adopting circular manufacturing can significantly lower costs and enhance sustainability metrics, aligning with global regulatory demands and consumer preferences. Grasping these distinctions enables manufacturers to implement targeted strategies for cost reduction, innovation, and compliance with evolving environmental standards.

Comparison Table

| Aspect | Circular Manufacturing | Discrete Manufacturing |

|---|---|---|

| Definition | Focuses on sustainability by reusing materials and minimizing waste in a closed-loop system. | Produces distinct, separate products in batches or units, often on assembly lines. |

| Waste Management | Minimizes waste through recycling and remanufacturing. | Generates more waste due to one-time use materials and processes. |

| Resource Usage | Optimizes resource efficiency by circular reuse and material recovery. | Uses resources linearly - raw material to finished product to disposal. |

| Product Lifecycle | Extends lifecycle by design for reuse, repair, or refurbishment. | Typically shorter lifecycle with limited reuse or repair opportunities. |

| Production Process | Designed with recycling and sustainability integrated into production. | Focused on mass production with set process steps per unit. |

| Examples | Eco-friendly packaging, remanufactured electronics. | Automobiles, electronics, appliances manufacturing. |

| Environmental Impact | Lower carbon footprint, reduced landfill waste. | Higher environmental footprint due to resource depletion and waste. |

| Business Model | Emphasizes product as a service, leasing, and take-back programs. | Primarily product sales based, with less emphasis on reuse. |

Which is better?

Circular manufacturing focuses on sustainability by reusing materials and minimizing waste throughout the production cycle, making it ideal for industries aiming to reduce environmental impact. Discrete manufacturing involves producing distinct items typically assembled from individual parts, offering flexibility and efficiency in sectors like automotive and electronics. Choosing between the two depends on priorities such as sustainability goals versus production volume and product customization requirements.

Connection

Circular manufacturing and discrete manufacturing intersect through the integration of sustainable practices into production processes that involve assembling distinct parts. Discrete manufacturing benefits from circular principles by adopting resource-efficient recycling, remanufacturing, and waste reduction strategies, extending the lifecycle of components and minimizing environmental impact. This synergy enhances supply chain resilience and operational efficiency while promoting eco-friendly product design and end-of-life management.

Key Terms

Bill of Materials (BOM)

Discrete manufacturing relies on a fixed Bill of Materials (BOM) outlining specific components and quantities required for each product, ensuring precise assembly and inventory control. Circular manufacturing integrates dynamic BOMs that accommodate product refurbishment, component reuse, and material recycling, promoting sustainability and reducing waste. Explore how adapting BOM strategies can optimize efficiency and environmental impact in both manufacturing models.

Recycling Loop

Discrete manufacturing produces distinct, countable products, often generating waste that ends up in landfills, whereas circular manufacturing emphasizes a recycling loop to minimize waste and reuse materials continuously. The recycling loop in circular manufacturing involves collecting, processing, and reintegrating materials back into production, significantly reducing resource consumption and environmental impact. Explore how integrating recycling loops transforms manufacturing sustainability and efficiency.

Product Lifecycle

Discrete manufacturing emphasizes the production of distinct items through linear processes, often resulting in significant waste after product use. Circular manufacturing integrates sustainable practices by designing products for reuse, refurbishment, and recycling, extending the product lifecycle and minimizing environmental impact. Discover how circular manufacturing transforms traditional production models for enhanced sustainability.

Source and External Links

Discrete manufacturing - Discrete manufacturing is the production of items that are distinct and easily identifiable from one another, such as automobiles, furniture, and smartphones, often involving individual or separate unit production that can be low volume/high complexity or high volume/low complexity.

Discrete vs. Process Manufacturing - How Do They Differ? - Discrete manufacturing produces goods from individual components and sub-assemblies using bills of materials and sequential assembly, with examples including car manufacturers producing various models assembled from thousands of parts.

Discrete Manufacturing - Typically characterized by work orders producing specific quantities of single items, with routing instructions for independent operations, discrete manufacturing suits make-to-stock, make-to-order, assemble-to-order, or engineer-to-order strategies for products like cars, furniture, electronics, and airplanes.

dowidth.com

dowidth.com