Industrial Internet leverages connected devices and real-time data analytics to optimize manufacturing processes and enhance operational efficiency. Product Lifecycle Management (PLM) centralizes design, development, and production information, enabling seamless collaboration and streamlined product workflows. Discover how integrating Industrial Internet with PLM transforms manufacturing agility and innovation.

Why it is important

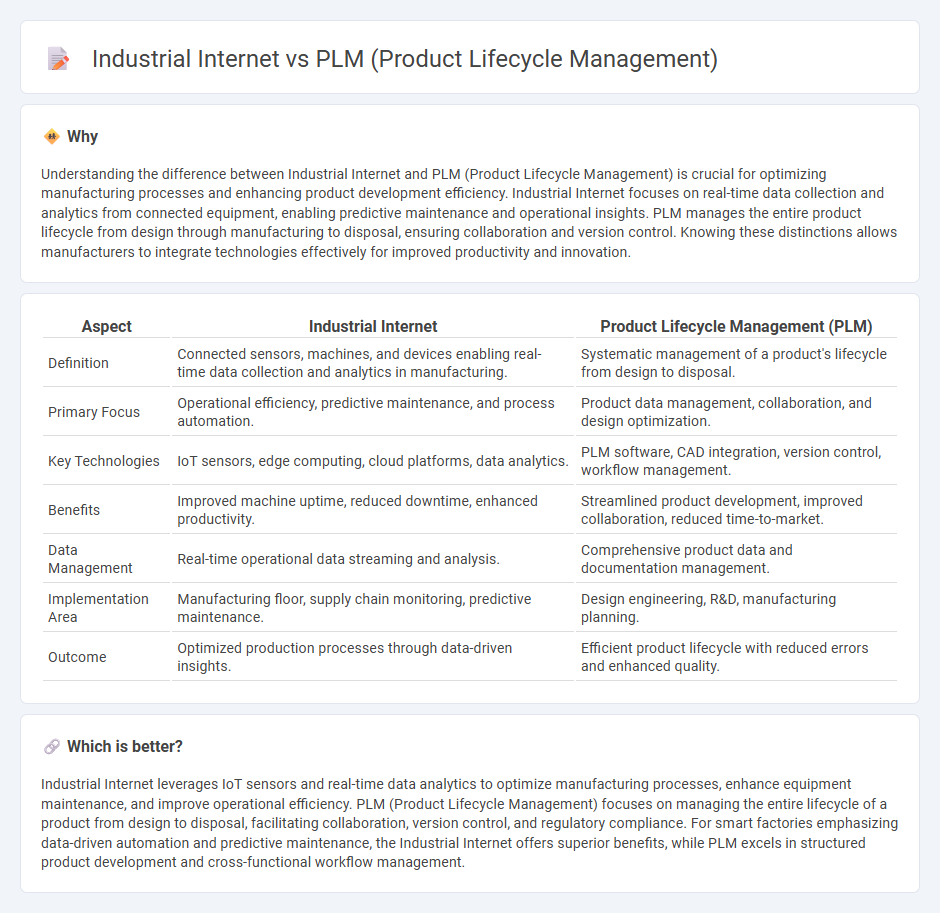

Understanding the difference between Industrial Internet and PLM (Product Lifecycle Management) is crucial for optimizing manufacturing processes and enhancing product development efficiency. Industrial Internet focuses on real-time data collection and analytics from connected equipment, enabling predictive maintenance and operational insights. PLM manages the entire product lifecycle from design through manufacturing to disposal, ensuring collaboration and version control. Knowing these distinctions allows manufacturers to integrate technologies effectively for improved productivity and innovation.

Comparison Table

| Aspect | Industrial Internet | Product Lifecycle Management (PLM) |

|---|---|---|

| Definition | Connected sensors, machines, and devices enabling real-time data collection and analytics in manufacturing. | Systematic management of a product's lifecycle from design to disposal. |

| Primary Focus | Operational efficiency, predictive maintenance, and process automation. | Product data management, collaboration, and design optimization. |

| Key Technologies | IoT sensors, edge computing, cloud platforms, data analytics. | PLM software, CAD integration, version control, workflow management. |

| Benefits | Improved machine uptime, reduced downtime, enhanced productivity. | Streamlined product development, improved collaboration, reduced time-to-market. |

| Data Management | Real-time operational data streaming and analysis. | Comprehensive product data and documentation management. |

| Implementation Area | Manufacturing floor, supply chain monitoring, predictive maintenance. | Design engineering, R&D, manufacturing planning. |

| Outcome | Optimized production processes through data-driven insights. | Efficient product lifecycle with reduced errors and enhanced quality. |

Which is better?

Industrial Internet leverages IoT sensors and real-time data analytics to optimize manufacturing processes, enhance equipment maintenance, and improve operational efficiency. PLM (Product Lifecycle Management) focuses on managing the entire lifecycle of a product from design to disposal, facilitating collaboration, version control, and regulatory compliance. For smart factories emphasizing data-driven automation and predictive maintenance, the Industrial Internet offers superior benefits, while PLM excels in structured product development and cross-functional workflow management.

Connection

The industrial internet integrates IoT sensors and data analytics within manufacturing systems, enhancing real-time monitoring and predictive maintenance. PLM systems leverage this data to streamline product design, development, and lifecycle management, improving collaboration across departments. This synergy optimizes production efficiency, reduces downtime, and accelerates time-to-market for manufacturing enterprises.

Key Terms

PLM (Product Lifecycle Management):

PLM (Product Lifecycle Management) serves as a foundational framework for managing the complete lifecycle of a product from inception through design, manufacturing, and disposal, integrating essential data and processes across departments. Industrial Internet, on the other hand, leverages IoT, big data, and analytics to optimize real-time operations and product performance, often relying on PLM systems for historical and design context. Explore how combining advanced PLM strategies with Industrial Internet technologies drives innovation and efficiency in smart manufacturing.

BOM (Bill of Materials)

Product Lifecycle Management (PLM) systems centralize BOM (Bill of Materials) data to streamline product design, engineering changes, and regulatory compliance throughout the product lifecycle. Industrial Internet platforms enhance BOM management by integrating real-time sensor data and operational analytics from IoT devices, enabling predictive maintenance and dynamic inventory optimization. Explore how combining PLM with Industrial Internet technologies transforms BOM accuracy and operational efficiency.

Change Management

Product Lifecycle Management (PLM) systems centralize data and processes to streamline product changes, ensuring traceability, version control, and collaboration across teams. Industrial Internet technologies enhance Change Management by integrating real-time sensor data and predictive analytics to anticipate and address product issues faster. Explore how combining PLM with industrial internet accelerates efficient Change Management in manufacturing.

Source and External Links

Product lifecycle - Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from inception through engineering, design, manufacture, service, and disposal, integrating people, data, processes, and business systems for a company-wide product information backbone.

What Is PLM Software? | Product Lifecycle Management - PLM software manages all information and processes across a product's lifecycle globally, supporting development, service, and disposal, and helping businesses unify product value chains for faster innovation and improved product quality.

Product Life Cycle Management (PLM) Explained - PLM integrates information, processes, and people from development, marketing, and service with key phases of product design and development, manufacturing, and distribution to improve coordination, quality assurance, and market delivery.

dowidth.com

dowidth.com