Dark factories operate without human presence during production, relying on full automation, robotics, and AI to maintain continuous manufacturing processes. Lights-out manufacturing optimizes efficiency by eliminating the need for lighting and human intervention, reducing operational costs and minimizing errors. Explore further to understand how these cutting-edge manufacturing models transform industrial productivity.

Why it is important

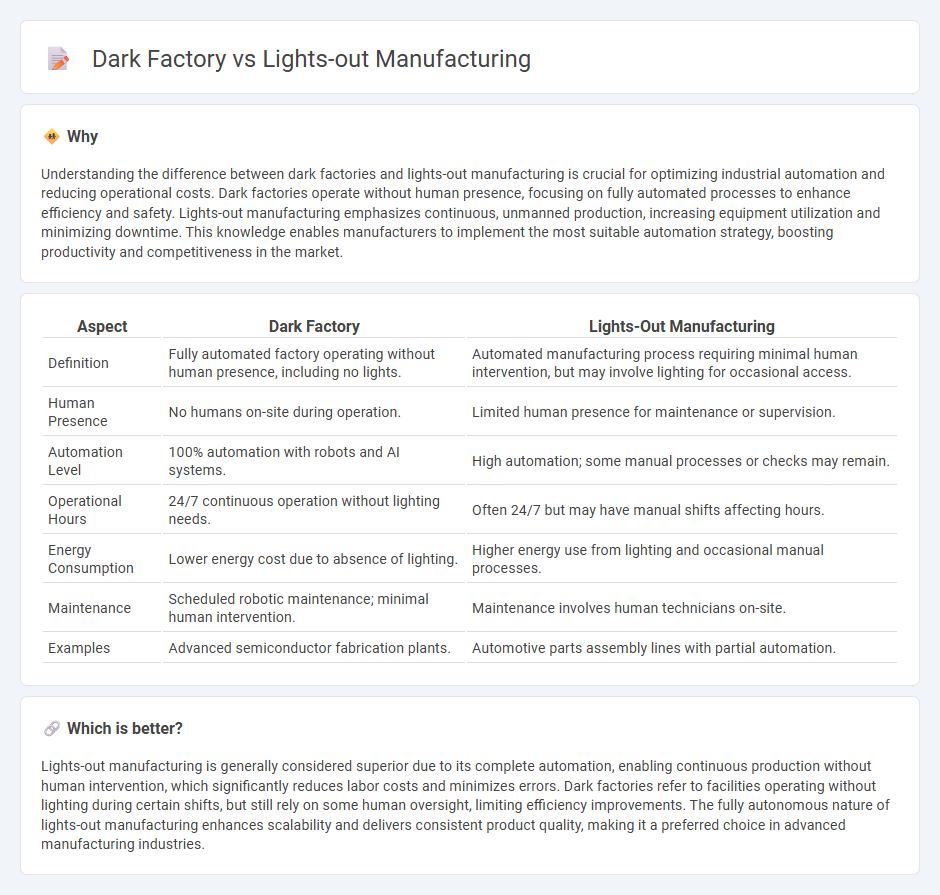

Understanding the difference between dark factories and lights-out manufacturing is crucial for optimizing industrial automation and reducing operational costs. Dark factories operate without human presence, focusing on fully automated processes to enhance efficiency and safety. Lights-out manufacturing emphasizes continuous, unmanned production, increasing equipment utilization and minimizing downtime. This knowledge enables manufacturers to implement the most suitable automation strategy, boosting productivity and competitiveness in the market.

Comparison Table

| Aspect | Dark Factory | Lights-Out Manufacturing |

|---|---|---|

| Definition | Fully automated factory operating without human presence, including no lights. | Automated manufacturing process requiring minimal human intervention, but may involve lighting for occasional access. |

| Human Presence | No humans on-site during operation. | Limited human presence for maintenance or supervision. |

| Automation Level | 100% automation with robots and AI systems. | High automation; some manual processes or checks may remain. |

| Operational Hours | 24/7 continuous operation without lighting needs. | Often 24/7 but may have manual shifts affecting hours. |

| Energy Consumption | Lower energy cost due to absence of lighting. | Higher energy use from lighting and occasional manual processes. |

| Maintenance | Scheduled robotic maintenance; minimal human intervention. | Maintenance involves human technicians on-site. |

| Examples | Advanced semiconductor fabrication plants. | Automotive parts assembly lines with partial automation. |

Which is better?

Lights-out manufacturing is generally considered superior due to its complete automation, enabling continuous production without human intervention, which significantly reduces labor costs and minimizes errors. Dark factories refer to facilities operating without lighting during certain shifts, but still rely on some human oversight, limiting efficiency improvements. The fully autonomous nature of lights-out manufacturing enhances scalability and delivers consistent product quality, making it a preferred choice in advanced manufacturing industries.

Connection

Dark factories operate without human presence, relying on automation and robotics to perform manufacturing tasks, which is the core principle of lights-out manufacturing. Lights-out manufacturing emphasizes continuous production processes controlled remotely or autonomously, enhancing efficiency and reducing labor costs. Both concepts leverage advanced technologies such as AI, IoT, and machine learning to optimize factory operations and minimize human intervention.

Key Terms

Automation

Lights-out manufacturing refers to fully automated production systems operating without human presence, often in controlled environments using robotics, AI, and advanced sensors to optimize efficiency and reduce errors. Dark factories take this concept further by eliminating all human intervention entirely, including maintenance tasks, enabling continuous 24/7 operation and maximizing production throughput. Explore the latest technologies and strategies driving these innovations in automation to enhance manufacturing performance.

Human Intervention

Lights-out manufacturing operates with minimal but some human intervention for monitoring and maintenance, whereas a dark factory is fully autonomous, running entirely without human presence during production. Both systems leverage automation and robotics to optimize efficiency and reduce errors, but lights-out manufacturing allows periodic human oversight to address unexpected issues. Explore the distinctions and operational implications of these advanced manufacturing models to better understand their impact on industry.

Robotics

Lights-out manufacturing leverages fully automated robotic systems operating without human intervention during production shifts, maximizing efficiency and minimizing errors. Dark factories take this concept further by eliminating human presence entirely, relying on advanced robotics, AI, and IoT technologies to run manufacturing processes 24/7 in completely unlit environments. Discover more about how robotics innovation drives these futuristic manufacturing models.

Source and External Links

Lights-out factory - Siemens Digital Industries Software - A lights-out factory, also known as a dark factory, operates with minimal human activity, allowing fully automated manufacturing with robots and software to run production processes independently, ideal for simple mass production or "lights-sparse" factories handling more complex products.

What is Lights Out Manufacturing? Exploring Full Automation - Lights-out manufacturing uses fully automated technology to run production facilities 24/7 with little or no human intervention, leading to reduced labor costs, fewer accidents, and consistent quality.

What is "Lights Out" Dark Manufacturing? | ATS - Dark factories are automated plants relying on robotics, AI, and IoT that can operate without human presence, driven by factors including labor shortages and cost pressures, with benefits like increased efficiency and lower overhead.

dowidth.com

dowidth.com