Factory as a Service (FaaS) provides scalable, cloud-connected manufacturing resources that allow businesses to outsource production without investing in physical infrastructure, while On-Demand Manufacturing delivers custom products quickly by utilizing a network of flexible factories. Both models emphasize agility, reduced lead times, and cost efficiency, transforming traditional manufacturing paradigms through digital integration and automation. Explore how these innovative manufacturing solutions can optimize your supply chain and accelerate product development.

Why it is important

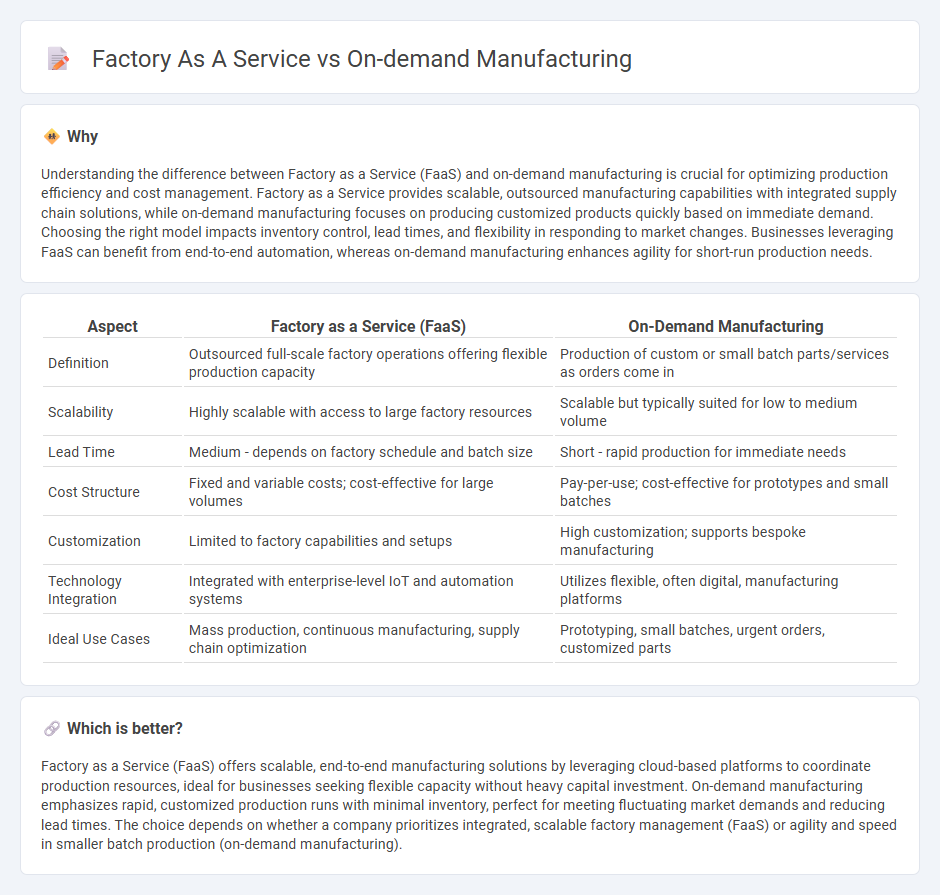

Understanding the difference between Factory as a Service (FaaS) and on-demand manufacturing is crucial for optimizing production efficiency and cost management. Factory as a Service provides scalable, outsourced manufacturing capabilities with integrated supply chain solutions, while on-demand manufacturing focuses on producing customized products quickly based on immediate demand. Choosing the right model impacts inventory control, lead times, and flexibility in responding to market changes. Businesses leveraging FaaS can benefit from end-to-end automation, whereas on-demand manufacturing enhances agility for short-run production needs.

Comparison Table

| Aspect | Factory as a Service (FaaS) | On-Demand Manufacturing |

|---|---|---|

| Definition | Outsourced full-scale factory operations offering flexible production capacity | Production of custom or small batch parts/services as orders come in |

| Scalability | Highly scalable with access to large factory resources | Scalable but typically suited for low to medium volume |

| Lead Time | Medium - depends on factory schedule and batch size | Short - rapid production for immediate needs |

| Cost Structure | Fixed and variable costs; cost-effective for large volumes | Pay-per-use; cost-effective for prototypes and small batches |

| Customization | Limited to factory capabilities and setups | High customization; supports bespoke manufacturing |

| Technology Integration | Integrated with enterprise-level IoT and automation systems | Utilizes flexible, often digital, manufacturing platforms |

| Ideal Use Cases | Mass production, continuous manufacturing, supply chain optimization | Prototyping, small batches, urgent orders, customized parts |

Which is better?

Factory as a Service (FaaS) offers scalable, end-to-end manufacturing solutions by leveraging cloud-based platforms to coordinate production resources, ideal for businesses seeking flexible capacity without heavy capital investment. On-demand manufacturing emphasizes rapid, customized production runs with minimal inventory, perfect for meeting fluctuating market demands and reducing lead times. The choice depends on whether a company prioritizes integrated, scalable factory management (FaaS) or agility and speed in smaller batch production (on-demand manufacturing).

Connection

Factory as a Service (FaaS) and on-demand manufacturing are interconnected through their shared focus on flexible, scalable production capabilities facilitated by digital platforms. FaaS leverages cloud-based infrastructure to provide manufacturers with real-time access to factory resources and equipment, enabling rapid response to market demands. On-demand manufacturing utilizes this model to produce customized products efficiently without the need for large inventory investments, optimizing supply chains and reducing lead times.

Key Terms

Customization

On-demand manufacturing excels in customization by producing unique, low-volume products tailored to specific requirements through flexible digital workflows and rapid prototyping. Factory as a Service (FaaS) offers scalable customization by providing access to advanced manufacturing infrastructure and expertise on a subscription basis, enabling clients to customize production without heavy capital investment. Explore the differences in customization capabilities and benefits of these models for your manufacturing needs.

Scalability

On-demand manufacturing offers rapid scalability by utilizing flexible production resources tailored to fluctuating customer demands without significant upfront capital investment. Factory as a Service (FaaS) provides scalable manufacturing capabilities through cloud-based platforms that integrate automation, real-time data analytics, and modular equipment to efficiently adjust output levels. Explore more to understand which solution best aligns with your scalability needs.

Digital Platform

On-demand manufacturing leverages digital platforms to enable real-time production scalability, reducing inventory costs and accelerating time-to-market through cloud-based order processing and AI-driven resource allocation. Factory as a Service (FaaS) uses digital platforms to provide flexible, accessible manufacturing capacity by connecting users to a network of smart factories equipped with IoT and automation for on-demand production. Explore how these digital platforms transform manufacturing ecosystems for enhanced efficiency and responsiveness.

Source and External Links

On-Demand Manufacturing: The Future of Production | MakerVerse - On-demand manufacturing is a model where products are made only after receiving specific orders, offering benefits like lower inventory costs, faster time-to-market, and greater flexibility compared to traditional mass production methods by leveraging technologies such as 3D printing and CNC machining.

On-Demand Manufacturing Basics: How It Works and Pros & Cons - This system enables production based on customer demands, emphasizing low-volume, customized manufacturing, cost-effective small-batch orders, and faster turnaround times due to reduced lead times and instant quoting on CAD models.

On-Demand manufacturing: Get a quote | Dassault Systemes(r) - On-demand manufacturing produces parts exactly as needed, replacing traditional large-batch production; it operates via digital platforms where users upload designs, get instant quotes, select manufacturers, and track production in real-time, improving transparency and adaptability.

dowidth.com

dowidth.com